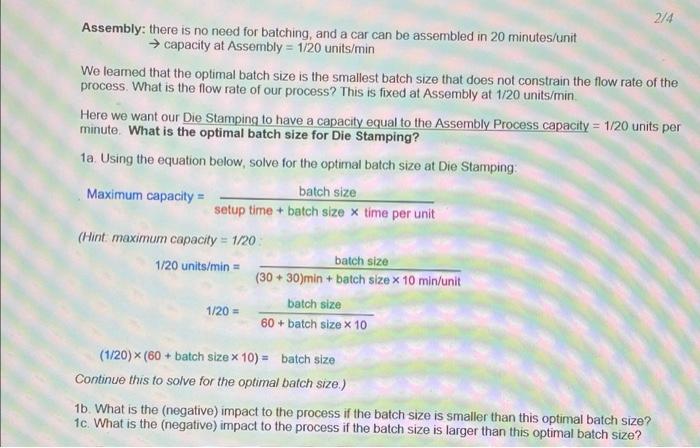

Question: 2/4 Assembly: there is no need for batching, and a car can be assembled in 20 minutes/unit capacity at Assembly = 1/20 units/min We leamed

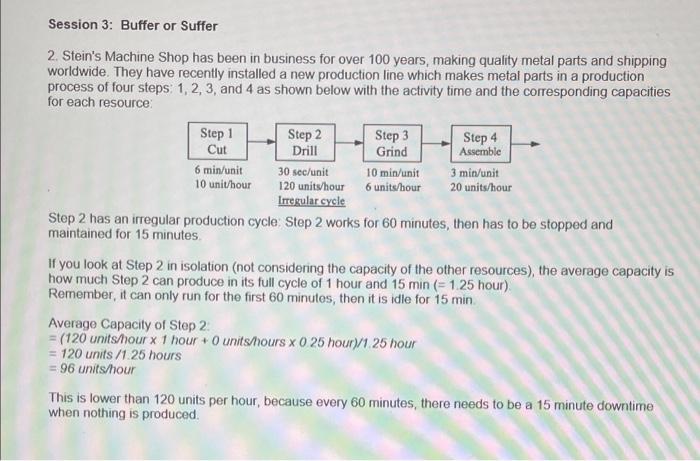

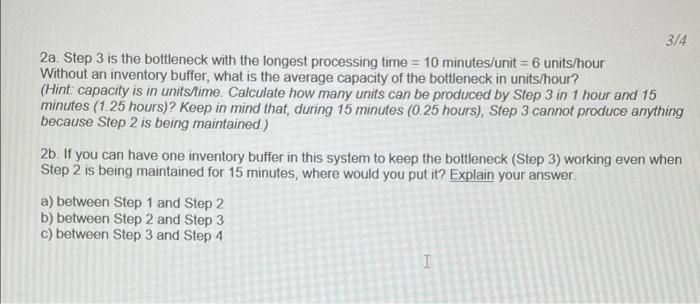

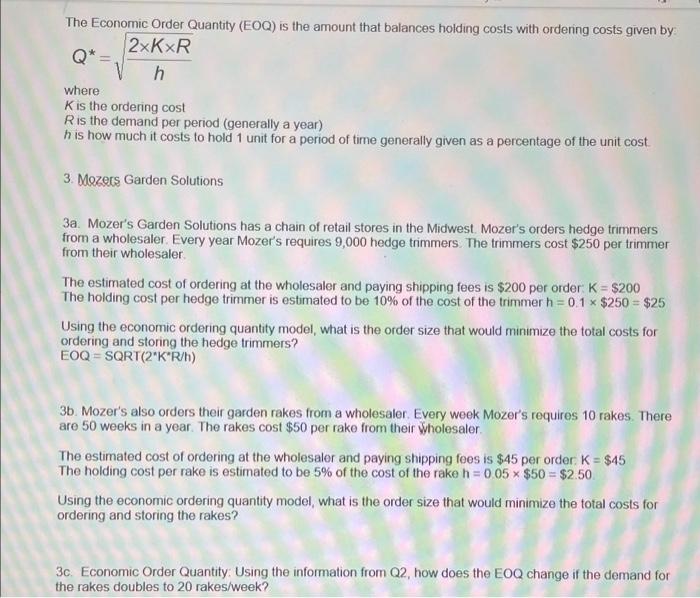

2/4 Assembly: there is no need for batching, and a car can be assembled in 20 minutes/unit capacity at Assembly = 1/20 units/min We leamed that the optimal batch size is the smallest batch size that does not constrain the flow rate of the process. What is the flow rate of our process? This is fixed at Assembly at 1/20 units/min Here we want our Die Stamping to have a capacity equal to the Assembly Process capacity = 1/20 units per minute. What is the optimal batch size for Die Stamping? 1a Using the equation below, solve for the optirnal batch size at Die Stamping: Maximum capacity = batch size setup time + batch size x time per unit (Hint maximum capacity = 1/20 batch size 1/20 units/min (30 + 30)min + batch size x 10 min/unit 1/20 = batch size 60+ batch size x 10 (1/20) > (60 + batch size x 10) = batch size Continue this to solve for the optimal batch size) 16. What is the (negative) impact to the process if the batch size is smaller than this optimal batch size? 1c. What is the (negative) impact to the process if the batch size is larger than this optimal batch size? Session 3: Buffer or Suffer 2. Stein's Machine Shop has been in business for over 100 years, making quality metal parts and shipping worldwide. They have recently installed a new production line which makes metal parts in a production process of four steps: 1,2,3, and 4 as shown below with the activity time and the corresponding capacities for each resource Step 1 Step 2 Step 3 Step 4 Cut Drill Grind Assemble 6 min/unit 30 sec/unit 10 min/unit 3 min/unit 10 unit/hour 120 units/hour 6 units/hour 20 units/hour Irregular cycle Step 2 has an irregular production cycle: Step 2 works for 60 minutes, then has to be stopped and maintained for 15 minutes If you look at Step 2 in isolation (not considering the capacity of the other resources), the average capacity is how much Step 2 can produce in its full cycle of 1 hour and 15 min (= 1.25 hour) Remember, it can only run for the first 60 minutes, then it is idle for 15 min Average Capacity of Step 2 = (120 units/hour x 1 hour + 0 units/hours x 0 25 hour)/1.25 hour = 120 units /1.25 hours = 96 units/hour This is lower than 120 units per hour, because every 60 minutes, there needs to be a 15 minute downtime when nothing is produced 3/4 2a. Step 3 is the bottleneck with the longest processing time = 10 minutes/unit = 6 units/hour Without an inventory buffer, what is the average capacity of the bottleneck in units/hour? (Hintcapacity is in units/time. Calculate how many units can be produced by Step 3 in 1 hour and 15 minutes (1.25 hours)? Keep in mind that, during 15 minutes (0.25 hours), Step 3 cannot produce anything because Step 2 is being maintained) 2b. If you can have one inventory buffer in this system to keep the bottleneck (Step 3) working even when Step 2 is being maintained for 15 minutes, where would you put it? Explain your answer a) between Step 1 and Step 2 b) between Step 2 and Step 3 c) between Step 3 and Step 4 I The Economic Order Quantity (EOQ) is the amount that balances holding costs with ordering costs given by 2xKxR Q* h where K is the ordering cost Ris the demand per period (generally a year) his how much it costs to hold 1 unit for a period of time generally given as a percentage of the unit cost 3. Mozers Garden Solutions 3a. Mozer's Garden Solutions has a chain of retail stores in the Midwest. Mozer's orders hedge trimmers from a wholesaler. Every year Mozer's requires 9,000 hedge trimmers. The trimmers cost $250 per trimmer from their wholesaler The estimated cost of ordering at the wholesaler and paying shipping fees is $200 per order K = $200 The holding cost per hedge trimmer is estimated to be 10% of the cost of the trimmer h = 0.1 * $250 = $25 Using the economic ordering quantity model, what is the order size that would minimize the total costs for ordering and storing the hedge trimmers? EOQ = SQRT(2"K"R/h) 3b. Mozer's also orders their garden rakes from a wholesaler. Every week Mozer's requires 10 rakes. There are 50 weeks in a year. The rakes cost $50 per rake from their Wholesaler The estimated cost of ordering at the wholesaler and paying shipping fees is $45 per order K = $45 The holding cost per rake is estimated to be 5% of the cost of the rake h=005 * $50 = $2.50 Using the economic ordering quantity model, what is the order size that would minimize the total costs for ordering and storing the rakes? 3c Economic Order Quantity: Using the information from Q2, how does the EOQ change if the demand for the rakes doubles to 20 rakes/week? 2/4 Assembly: there is no need for batching, and a car can be assembled in 20 minutes/unit capacity at Assembly = 1/20 units/min We leamed that the optimal batch size is the smallest batch size that does not constrain the flow rate of the process. What is the flow rate of our process? This is fixed at Assembly at 1/20 units/min Here we want our Die Stamping to have a capacity equal to the Assembly Process capacity = 1/20 units per minute. What is the optimal batch size for Die Stamping? 1a Using the equation below, solve for the optirnal batch size at Die Stamping: Maximum capacity = batch size setup time + batch size x time per unit (Hint maximum capacity = 1/20 batch size 1/20 units/min (30 + 30)min + batch size x 10 min/unit 1/20 = batch size 60+ batch size x 10 (1/20) > (60 + batch size x 10) = batch size Continue this to solve for the optimal batch size) 16. What is the (negative) impact to the process if the batch size is smaller than this optimal batch size? 1c. What is the (negative) impact to the process if the batch size is larger than this optimal batch size? Session 3: Buffer or Suffer 2. Stein's Machine Shop has been in business for over 100 years, making quality metal parts and shipping worldwide. They have recently installed a new production line which makes metal parts in a production process of four steps: 1,2,3, and 4 as shown below with the activity time and the corresponding capacities for each resource Step 1 Step 2 Step 3 Step 4 Cut Drill Grind Assemble 6 min/unit 30 sec/unit 10 min/unit 3 min/unit 10 unit/hour 120 units/hour 6 units/hour 20 units/hour Irregular cycle Step 2 has an irregular production cycle: Step 2 works for 60 minutes, then has to be stopped and maintained for 15 minutes If you look at Step 2 in isolation (not considering the capacity of the other resources), the average capacity is how much Step 2 can produce in its full cycle of 1 hour and 15 min (= 1.25 hour) Remember, it can only run for the first 60 minutes, then it is idle for 15 min Average Capacity of Step 2 = (120 units/hour x 1 hour + 0 units/hours x 0 25 hour)/1.25 hour = 120 units /1.25 hours = 96 units/hour This is lower than 120 units per hour, because every 60 minutes, there needs to be a 15 minute downtime when nothing is produced 3/4 2a. Step 3 is the bottleneck with the longest processing time = 10 minutes/unit = 6 units/hour Without an inventory buffer, what is the average capacity of the bottleneck in units/hour? (Hintcapacity is in units/time. Calculate how many units can be produced by Step 3 in 1 hour and 15 minutes (1.25 hours)? Keep in mind that, during 15 minutes (0.25 hours), Step 3 cannot produce anything because Step 2 is being maintained) 2b. If you can have one inventory buffer in this system to keep the bottleneck (Step 3) working even when Step 2 is being maintained for 15 minutes, where would you put it? Explain your answer a) between Step 1 and Step 2 b) between Step 2 and Step 3 c) between Step 3 and Step 4 I The Economic Order Quantity (EOQ) is the amount that balances holding costs with ordering costs given by 2xKxR Q* h where K is the ordering cost Ris the demand per period (generally a year) his how much it costs to hold 1 unit for a period of time generally given as a percentage of the unit cost 3. Mozers Garden Solutions 3a. Mozer's Garden Solutions has a chain of retail stores in the Midwest. Mozer's orders hedge trimmers from a wholesaler. Every year Mozer's requires 9,000 hedge trimmers. The trimmers cost $250 per trimmer from their wholesaler The estimated cost of ordering at the wholesaler and paying shipping fees is $200 per order K = $200 The holding cost per hedge trimmer is estimated to be 10% of the cost of the trimmer h = 0.1 * $250 = $25 Using the economic ordering quantity model, what is the order size that would minimize the total costs for ordering and storing the hedge trimmers? EOQ = SQRT(2"K"R/h) 3b. Mozer's also orders their garden rakes from a wholesaler. Every week Mozer's requires 10 rakes. There are 50 weeks in a year. The rakes cost $50 per rake from their Wholesaler The estimated cost of ordering at the wholesaler and paying shipping fees is $45 per order K = $45 The holding cost per rake is estimated to be 5% of the cost of the rake h=005 * $50 = $2.50 Using the economic ordering quantity model, what is the order size that would minimize the total costs for ordering and storing the rakes? 3c Economic Order Quantity: Using the information from Q2, how does the EOQ change if the demand for the rakes doubles to 20 rakes/week