Question: 24.12 A process is being developed to deposit a thin film of electronic grade silicon (Si) onto the inner surface of a hollow glass optical

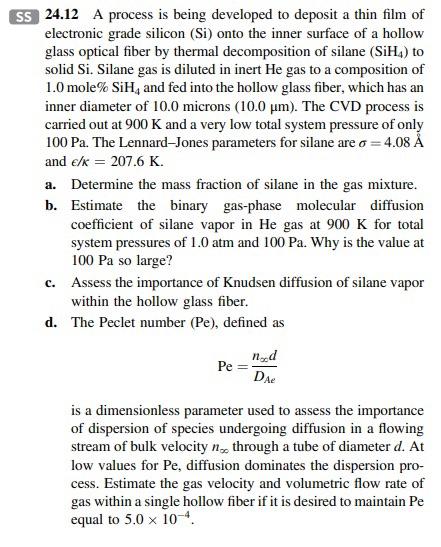

24.12 A process is being developed to deposit a thin film of electronic grade silicon (Si) onto the inner surface of a hollow glass optical fiber by thermal decomposition of silane (SiH4) to solid Si. Silane gas is diluted in inert He gas to a composition of 1.0 mole %SiH4 and fed into the hollow glass fiber, which has an inner diameter of 10.0 microns (10.0m). The CVD process is carried out at 900K and a very low total system pressure of only 100Pa. The Lennard-Jones parameters for silane are =4.08A and /=207.6K. a. Determine the mass fraction of silane in the gas mixture. b. Estimate the binary gas-phase molecular diffusion coefficient of silane vapor in He gas at 900K for total system pressures of 1.0 atm and 100Pa. Why is the value at 100Pa so large? c. Assess the importance of Knudsen diffusion of silane vapor within the hollow glass fiber. d. The Peclet number (Pe), defined as Pe=DAend is a dimensionless parameter used to assess the importance of dispersion of species undergoing diffusion in a flowing stream of bulk velocity n through a tube of diameter d. At low values for Pe, diffusion dominates the dispersion process. Estimate the gas velocity and volumetric flow rate of gas within a single hollow fiber if it is desired to maintain Pe equal to 5.0104

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts