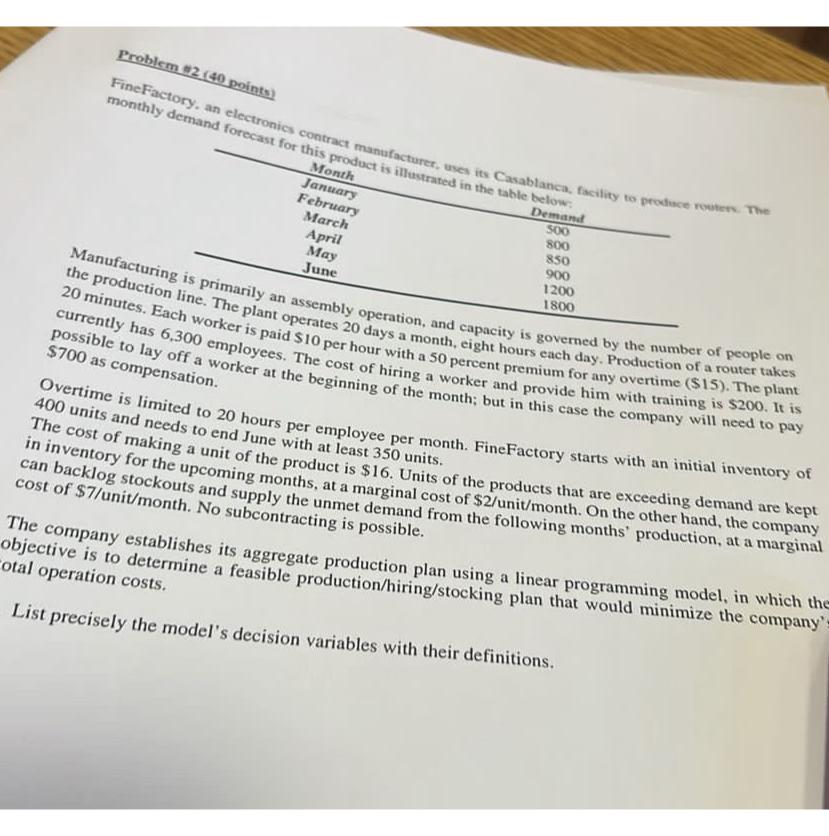

Question: 3 0 0 8 0 0 8 5 0 9 0 0 1 2 0 0 1 8 0 0 the production line. The plant

the production line. The plant operates days a month, eight hours each day. Production of a router takes minutes, Each worker is paid $ per hour with a percent premium for any overtime $ The plant currently has employees. The cost of hiring a worker and provide him with training is $ It is possible to lay off a w

$ as compensation.

Overtime is limited to hours per employee per month. FineFactory starts with an initial inventory of units and needs to end June with at least units.

The cost of making a unit of the product is $ Units of the products that are exceeding demand are kept in inventory for the upcoming months, at a marginal cost of $onth. On the other hand, the company can backlog stockouts and supply the unmet demand from the following month' production, at a marginal cost of $ unitmonth No subcontracting is possible.

The company establishes its aggregate production plan using a linear programming model, in which the objective is to determine a feasible productionhiringstocking plan that would minimize the company' otal operation costs.

List precisely the model's decision variables with their definitions.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock