Question: 3 6 5 days in a year assumption Setup cost per order Holding cost per unit per year Expected annual demand StDev of annual demand

days in a year assumption

Setup cost per order

Holding cost per unit per year

Expected annual demand

StDev of annual demand

Expected Lead time in years

StDev of Lead time in years

Expected demand during lead time

StDev of demand during lead time

Shortage penalty in a cycle.

Optimal solution using Solver to choose and

Changing cells

for Solver

Safety stock

Probability of a shortage during an ordering cycle

Reorder point

Willing to pay:

to get rid of the uncertainty

in shippingtime MicroApple & MacinDOS

days in a year assumption

Inputs

Optimal solution using Solver to choose and

Assessing the Stockout Costs Explicitly through p the Shortage Penalty

Changing cells

for Solver

Safety stock

Probability of a shortage during an ordering cycle

Reorder point

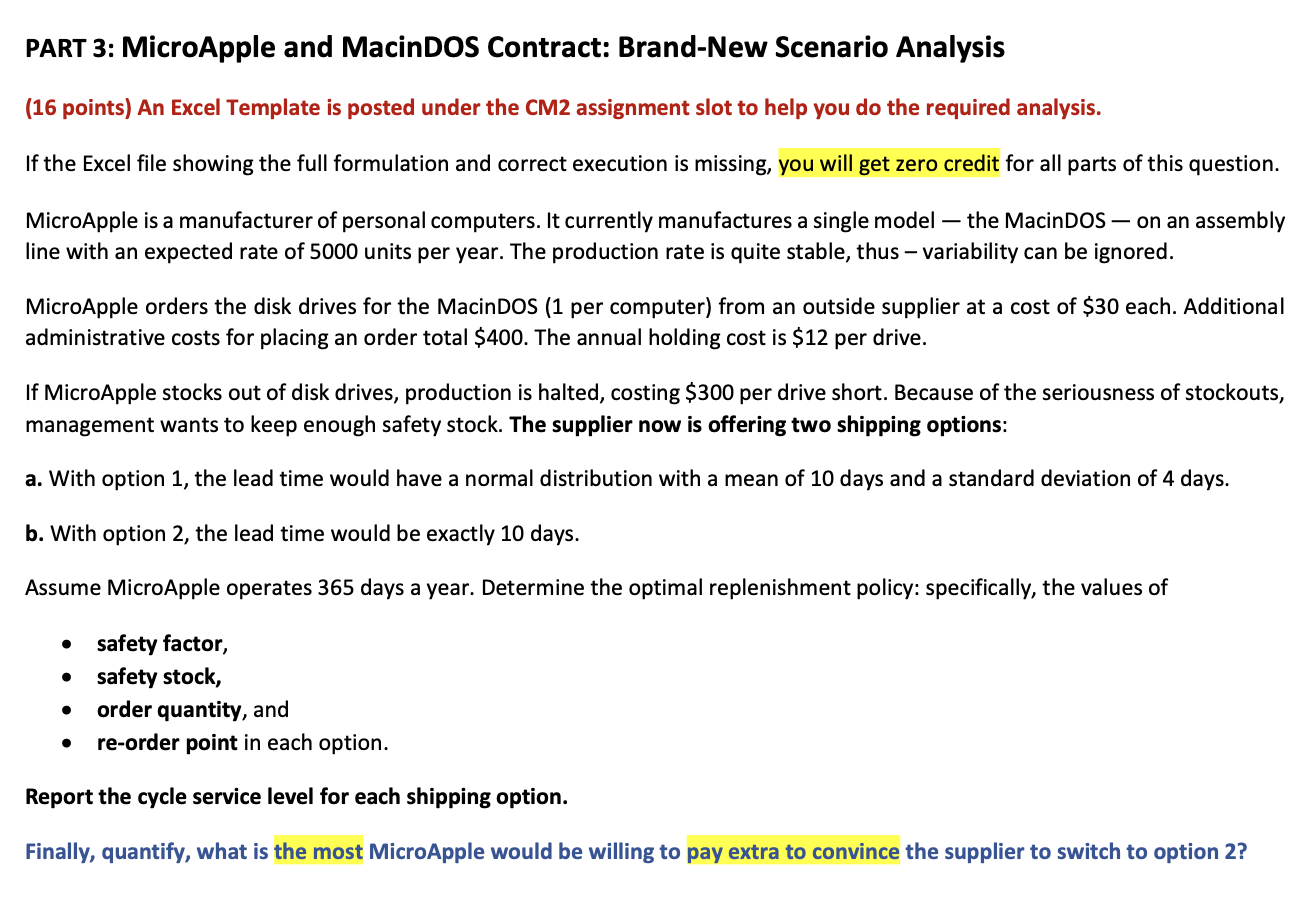

PART : MicroApple and MacinDOS Contract: BrandNew Scenario Analysis

points An Excel Template is posted under the CM assignment slot to help you do the required analysis.

If the Excel file showing the full formulation and correct execution is missing, you will get zero credit for all parts of this question.

MicroApple is a manufacturer of personal computers. It currently manufactures a single model the MacinDOS on an assembly line with an expected rate of units per year. The production rate is quite stable, thus variability can be ignored.

MicroApple orders the disk drives for the MacinDOS per computer from an outside supplier at a cost of $ each. Additional administrative costs for placing an order total $ The annual holding cost is $ per drive.

If MicroApple stocks out of disk drives, production is halted, costing $ per drive short. Because of the seriousness of stockouts, management wants to keep enough safety stock. The supplier now is offering two shipping options:

a With option the lead time would have a normal distribution with a mean of days and a standard deviation of days.

b With option the lead time would be exactly days.

Assume MicroApple operates days a year. Determine the optimal replenishment policy: specifically, the values of

safety factor,

safety stock,

order quantity, and

reorder point in each option.

Report the cycle service level for each shipping option.

Finally, quantify, what is the most MicroApple would be willing to pay extra to convince the supplier to switch to option

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock