Question: 3 - ( a ) A porous structure fabricated using additive manufacturing is modeled as a simply supported beam with a span L subjected to

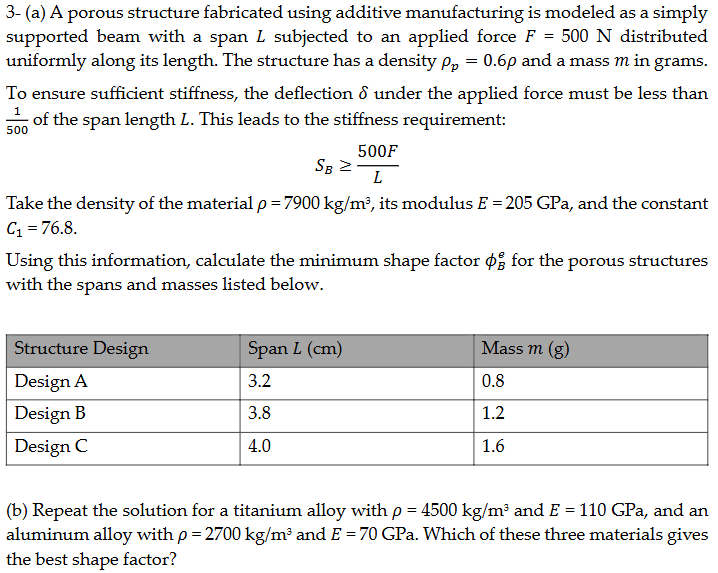

a A porous structure fabricated using additive manufacturing is modeled as a simply

supported beam with a span L subjected to an applied force FN distributed

uniformly along its length. The structure has a density rho prho and a mass m in grams.

To ensure sufficient stiffness, the deflection delta under the applied force must be less than

of the span length L This leads to the stiffness requirement:

SBFL

Take the density of the material rho kgm its modulus EGPa, and the constant

C

Using this information, calculate the minimum shape factor phi Be for the porous structures

with the spans and masses listed below.

b Repeat the solution for a titanium alloy with rho kgm and EGPa, and an

aluminum alloy with rho kgm and EGPa. Which of these three materials gives

the best shape factor?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock