Question: 3. A simplified flowsheet for a flotation process on a copper-nickel ore is shown below. This process would produce two valuable concentrates, one containing primarily

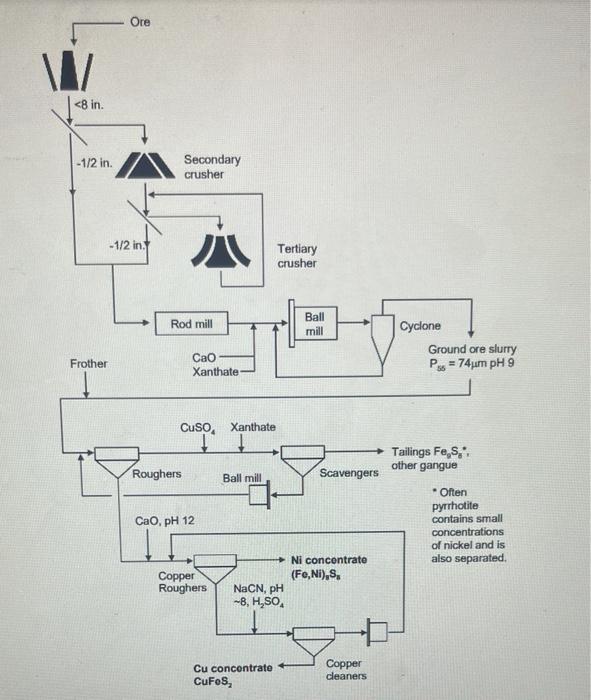

3. A simplified flowsheet for a flotation process on a copper-nickel ore is shown below. This process would produce two valuable concentrates, one containing primarily chalcopyrite and the other containing primarily pentlandite, i.e. (NI,Fe), S. (the sum of Fe + Ni is 9 moles per 8 moles sulfur). The ore also contains pyrrhotite, le Fe, S (x 0.05) and other gangue minerals. The ore is crushed to -8 inch at the mine site, then transported to the size reduction/flotation plant. The ore after primary crushing is first screened. -1/2 inch undersize is directed to product Oversize goes through secondary and tertiary crushing, with 1/2 inch size being the final crushed product. The crushed ore is directed to a two-stage grinding circuit. The ball mill product is classified with oversize being recycled to grinding and undersize reporting to the product stream. The ground ore is then sent to flotation First a copper-nickel concentrate is floated. The "tailings from the roughers go to scavengers where a low grade Ni-Cu concentrate is obtained. This is re-ground and then recycled to the roughers. The roughers Ni-Cu concentrate is treated to produce separate nickel and copper concentrates. In the copper roughers the pH is raised quite high to selectively float chalcopyrite. The tailings of this stage amounts to the nickel concentrate. The roughers copper concentrate is treated in cleaners flotation to produce a high grade copper concentrate and a moderate grade concentrate "tailings. The latter is reground and routed back to the copper roughers. There are many possible variations on this theme and actual flowsheets are more 2 complex Amyl xanthate is commonly used, but for this question assume ethyl xanthate is the collector Briefly explain your answers. (Critical pH curves are provided in the Introduction to Mineral Processing course notes.) (30) (a) Which parts of the size reduction process are operated in closed circuit fashion, and which in open circuit manner? (5) (b) is the overall flotation process more like a differential process or a bulk-selective process? (2) (c) Identify a differential circuit within the overall process. (2) (d) Identify two bulk-selective circuits within the overall process. (4) (e) Explain how the objectives of good grade and good recovery are achieved in the flotation process. (4) (1) A pH of 9 is used in rougher flotation to obtain a Ni Cu concentrate (1) How will this affect pyrrhotite in rougher flotation? () Would the critical pH curve for pentlandite le to the right or the left of pH 9 and the collector concentration used in this process? () Do you think the critical pH for pendlandite would lie to the left or the right of the curve for chalcopyrite? (6) (g) What is the purpose of NaCN addition to copper cleaner flotation? (2) (h) What is the purpose of the ball mills in the recycle streams in the flotation circuit? (2) (1) What are the purposes of the copper sulfate, collector and frother chemicals? (3) Ore

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts