Question: 3 ) Bracket Shearing and Bending The machine support bracket illustrated alongside must be manufactured from 5 mm low - carbon, commercial quality steel (

Bracket Shearing and Bending

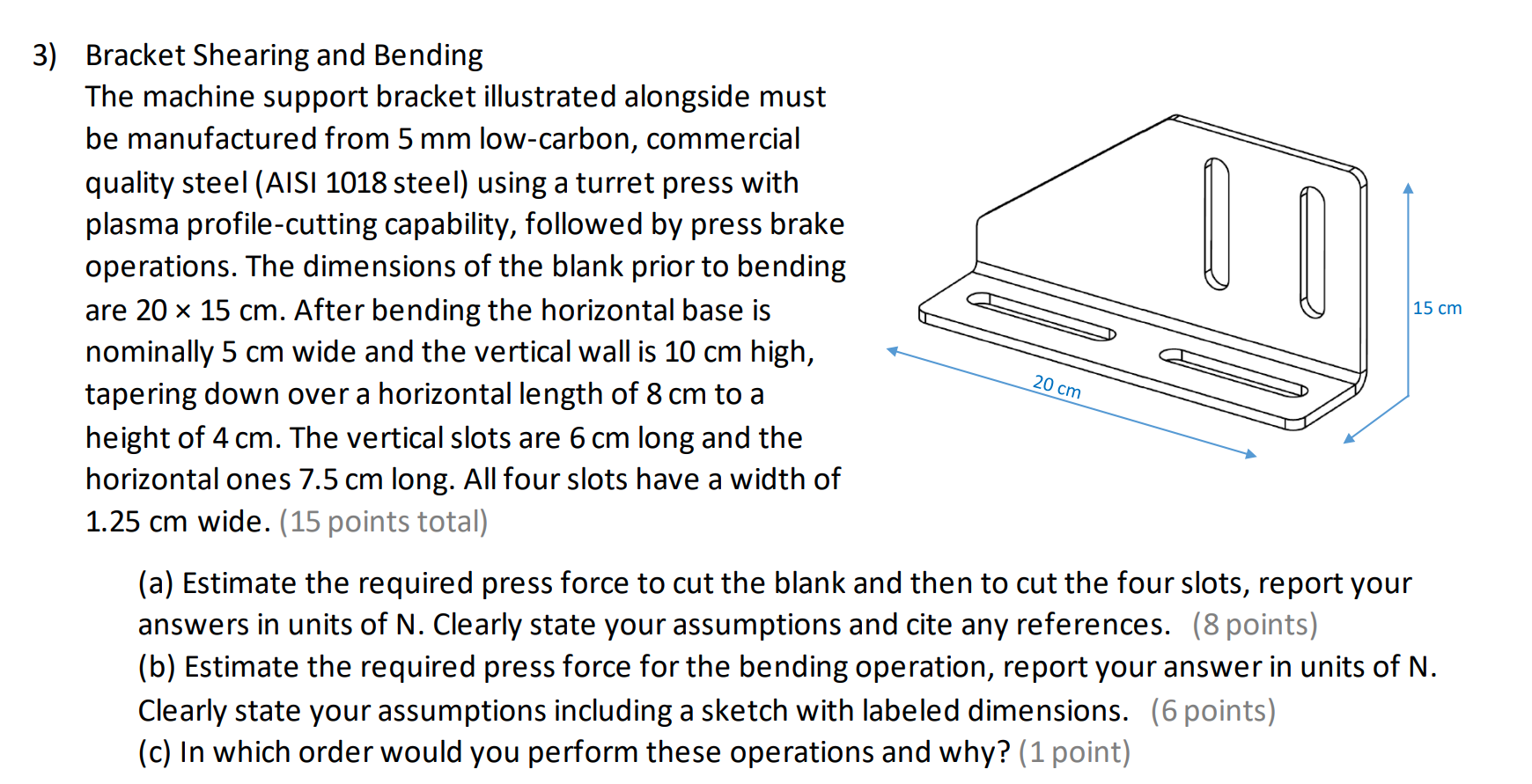

The machine support bracket illustrated alongside must be manufactured from mm lowcarbon, commercial quality steel AISI steel using a turret press with plasma profilecutting capability, followed by press brake operations. The dimensions of the blank prior to bending are times mathrm~cm After bending the horizontal base is nominally cm wide and the vertical wall is cm high, tapering down over a horizontal length of cm to a height of cm The vertical slots are cm long and the horizontal ones cm long. All four slots have a width of cm wide. points total

a Estimate the required press force to cut the blank and then to cut the four slots, report your answers in units of N Clearly state your assumptions and cite any references. points

b Estimate the required press force for the bending operation, report your answer in units of N

Clearly state your assumptions including a sketch with labeled dimensions. points

c In which order would you perform these operations and why? point

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock