Question: (3) Bumbee, Inc is a manufacturing company with operations in Columbus, Ohio and several other places, both in the United States and internationally. One segment

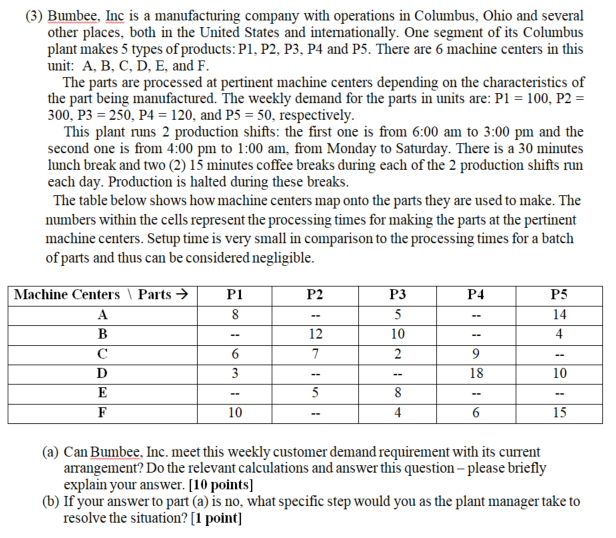

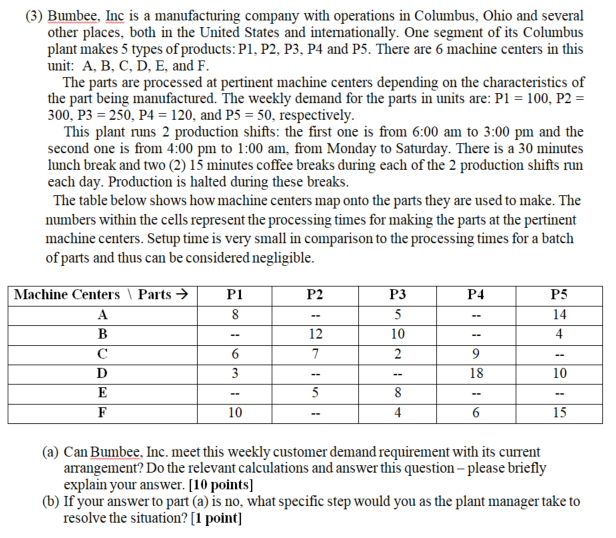

(3) Bumbee, Inc is a manufacturing company with operations in Columbus, Ohio and several other places, both in the United States and internationally. One segment of its Columbus plant makes 5 types of products: P1, P2, P3, P4 and P5. There are 6 machine centers in this unit: A, B, C, D, E, and F. The parts are processed at pertinent machine centers depending on the characteristics of the part being manufactured. The weekly demand for the parts in units are: P1 = 100, P2 = 300, P3 = 250, P4 = 120, and P5 = 50, respectively. This plant runs 2 production shifts: the first one is from 6:00 am to 3:00 pm and the second one is from 4:00 pm to 1:00 am, from Monday to Saturday. There is a 30 minutes lunch break and two (2) 15 minutes coffee breaks during each of the 2 production shifts run each day. Production is halted during these breaks. The table below shows how machine centers map onto the parts they are used to make. The numbers within the cells represent the processing times for making the parts at the pertinent machine centers. Setup time is very small in comparison to the processing times for a batch of parts and thus can be considered negligible. P1 P2 P4 8 Machine Centers Parts A B P3 5 10 2 P5 14 4 12 6 7 9 18 D 3 10 E 5 8 F 10 4 6 15 (a) Can Bumbee, Inc. meet this weekly customer demand requirement with its current arrangement? Do the relevant calculations and answer this question - please briefly explain your answer. [10 points] (6) If your answer to part (a) is no, what specific step would you as the plant manager take to resolve the situation? [1 point) (3) Bumbee, Inc is a manufacturing company with operations in Columbus, Ohio and several other places, both in the United States and internationally. One segment of its Columbus plant makes 5 types of products: P1, P2, P3, P4 and P5. There are 6 machine centers in this unit: A, B, C, D, E, and F. The parts are processed at pertinent machine centers depending on the characteristics of the part being manufactured. The weekly demand for the parts in units are: P1 = 100, P2 = 300, P3 = 250, P4 = 120, and P5 = 50, respectively. This plant runs 2 production shifts: the first one is from 6:00 am to 3:00 pm and the second one is from 4:00 pm to 1:00 am, from Monday to Saturday. There is a 30 minutes lunch break and two (2) 15 minutes coffee breaks during each of the 2 production shifts run each day. Production is halted during these breaks. The table below shows how machine centers map onto the parts they are used to make. The numbers within the cells represent the processing times for making the parts at the pertinent machine centers. Setup time is very small in comparison to the processing times for a batch of parts and thus can be considered negligible. P1 P2 P4 8 Machine Centers Parts A B P3 5 10 2 P5 14 4 12 6 7 9 18 D 3 10 E 5 8 F 10 4 6 15 (a) Can Bumbee, Inc. meet this weekly customer demand requirement with its current arrangement? Do the relevant calculations and answer this question - please briefly explain your answer. [10 points] (6) If your answer to part (a) is no, what specific step would you as the plant manager take to resolve the situation? [1 point)