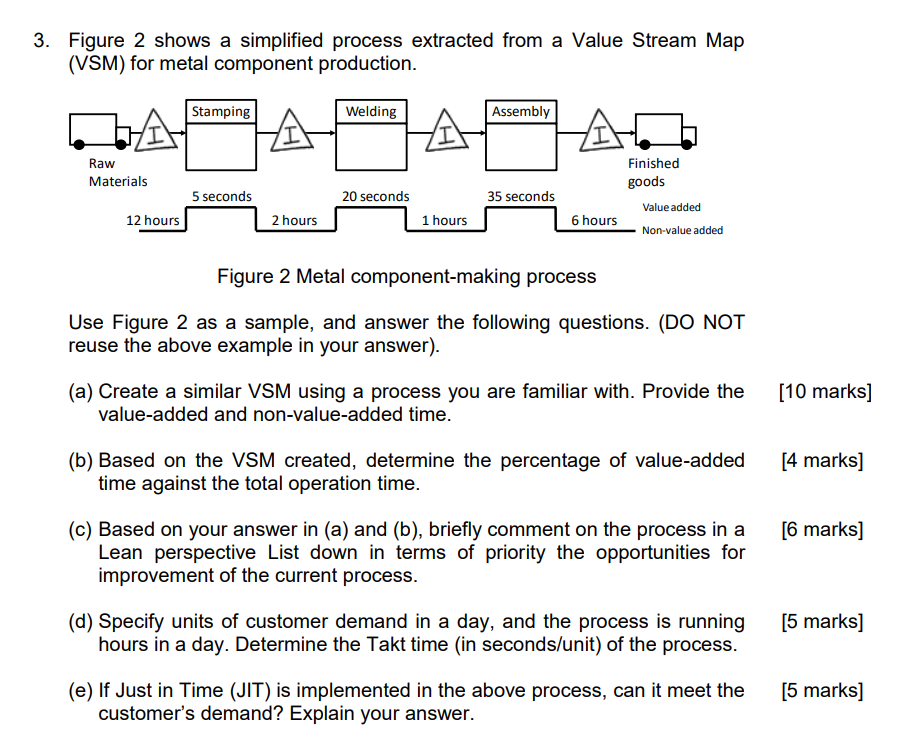

Question: 3. Figure 2 shows a simplified process extracted from a Value Stream Map (VSM) for metal component production. Figure 2 Metal component-making process Use Figure

3. Figure 2 shows a simplified process extracted from a Value Stream Map (VSM) for metal component production. Figure 2 Metal component-making process Use Figure 2 as a sample, and answer the following questions. (DO NOT reuse the above example in your answer). (a) Create a similar VSM using a process you are familiar with. Provide the value-added and non-value-added time. (b) Based on the VSM created, determine the percentage of value-added time against the total operation time. (c) Based on your answer in (a) and (b), briefly comment on the process in a Lean perspective List down in terms of priority the opportunities for improvement of the current process. (d) Specify units of customer demand in a day, and the process is running hours in a day. Determine the Takt time (in seconds/unit) of the process. [5 marks] (e) If Just in Time (JIT) is implemented in the above process, can it meet the [5 marks] customer's demand? Explain your answer. [10 marks] [4 marks] [6 marks] [5 marks] [5 marks]

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts