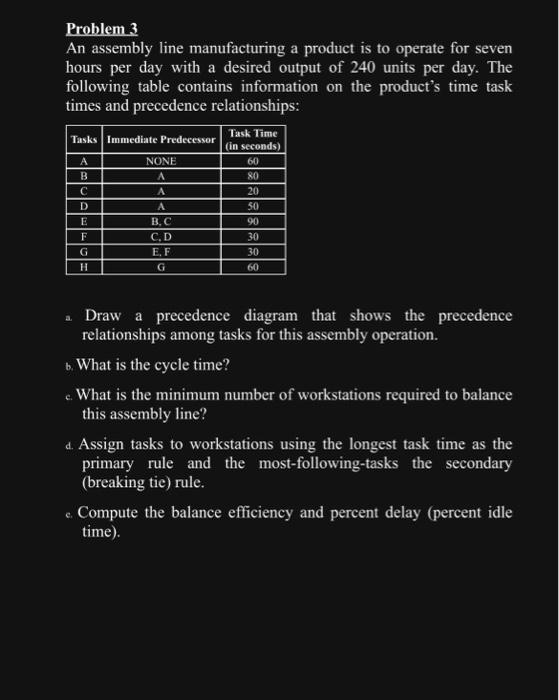

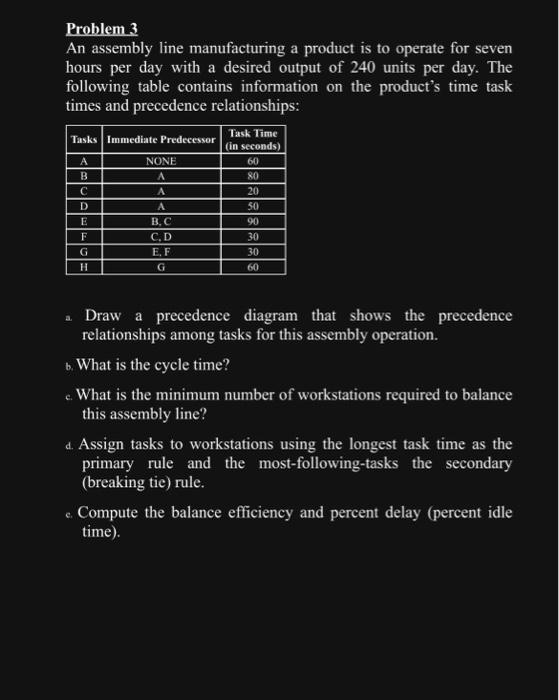

Question: 3 Problem 3 An assembly line manufacturing a product is to operate for seven hours per day with a desired output of 240 units per

3

Problem 3 An assembly line manufacturing a product is to operate for seven hours per day with a desired output of 240 units per day. The following table contains information on the product's time task times and precedence relationships: a Draw a precedence diagram that shows the precedence relationships among tasks for this assembly operation. b. What is the cycle time? c. What is the minimum number of workstations required to balance this assembly line? d. Assign tasks to workstations using the longest task time as the primary rule and the most-following-tasks the secondary (breaking tic) rule. c. Compute the balance efficiency and percent delay (percent idle time)

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock