Question: 3) The following table lists the components needed to assemble an end item, the manufacturing or purchase lead times (in weeks) for typical lot sizes,

3) The following table lists the components needed to assemble an end item, the manufacturing or purchase lead times (in weeks) for typical lot sizes, amount on hand, and the direct components of each item and, in brackets, the number of each component for each parent.LO2&LO3

| Item | Lead Time | Amount on Hand | Direct Components |

|---|---|---|---|

| End item | 1 | ? | L(2), C(1), K(3) |

| L | 2 | 10 | B(2), J(3) |

| C | 3 | 15 | G(2), B(2) |

| K | 3 | 20 | H(4), B(2) |

| B | 2 | 30 | |

| J | 3 | 30 | |

| G | 3 | 5 | |

| H | 2 | ? |

- Draw the product structure tree for the end item.

- If 40 units of the end item are to be assembled, how many additional units of B are needed? (You don't need to develop the MRP tables.)

- An order for 40 units of the end item is scheduled to be shipped at the start of week 8. What is the latest week that the components of the order can be started and the order still be ready to ship on time? (You don't need to develop the MRP tables.)

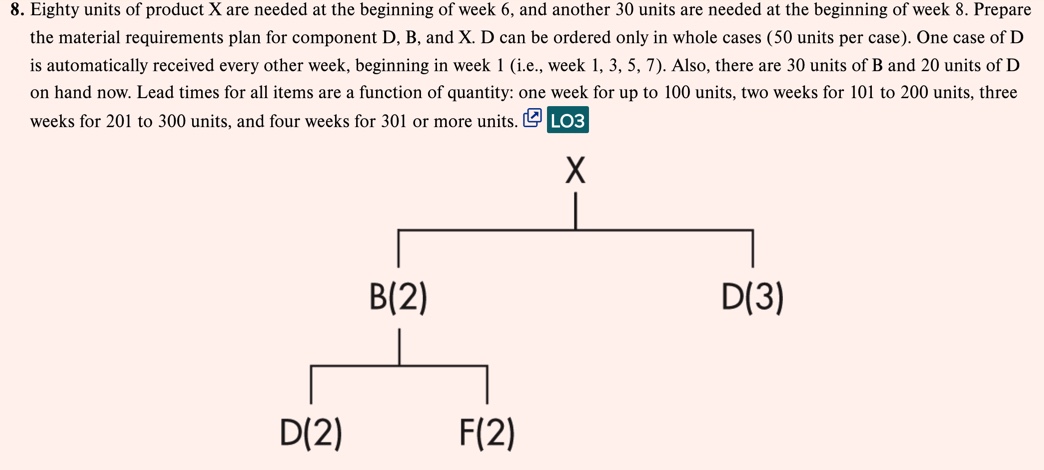

8. Eight):r units of product X are needed at the beginning of week 6, and another 30 units are needed at the beginning of week 8. Prepare the material requirements plan for component D, B, and X. D can be ordered only in whole cases (50 units per case). One case of D is automatically received every other week, beginning in week 1 (i.e., week I, 3. 5, '1'). Also, there are 30 units of B and 20 units of D on band now. Lead times for all items are a function of quantity: one week for up to 100 units, two weeks for 101 to 200 units, three weeks for 201 to 300 units. and four weeks for 30] or more units. X B(2] D(3) 0(2) H2)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts