Question: 3. You are to add/adjust constraint(s)/variables(s)/parameter(s)/objective function for Ex- ercise 3 from the second practice problem set (a copy of the problem is also on

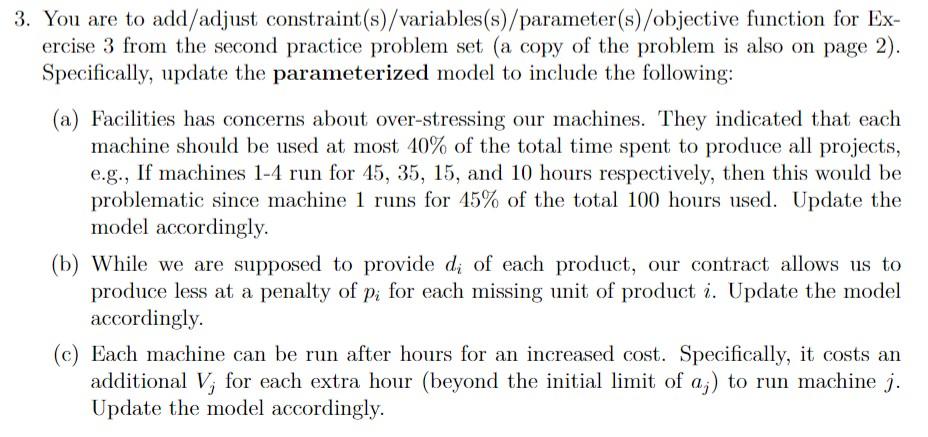

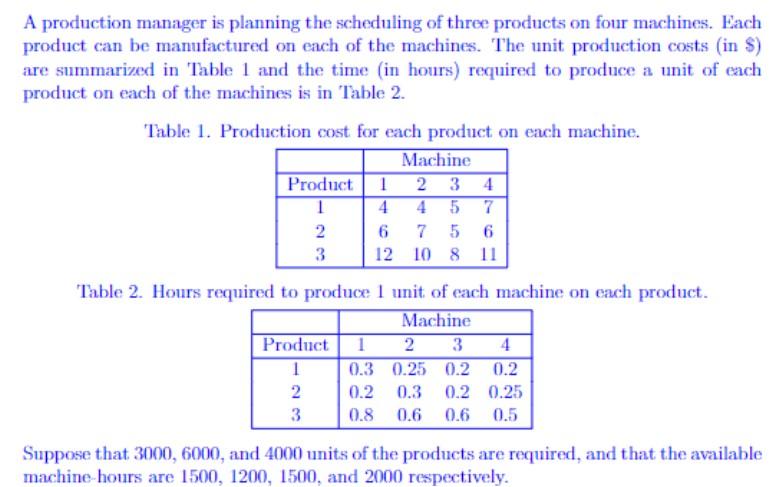

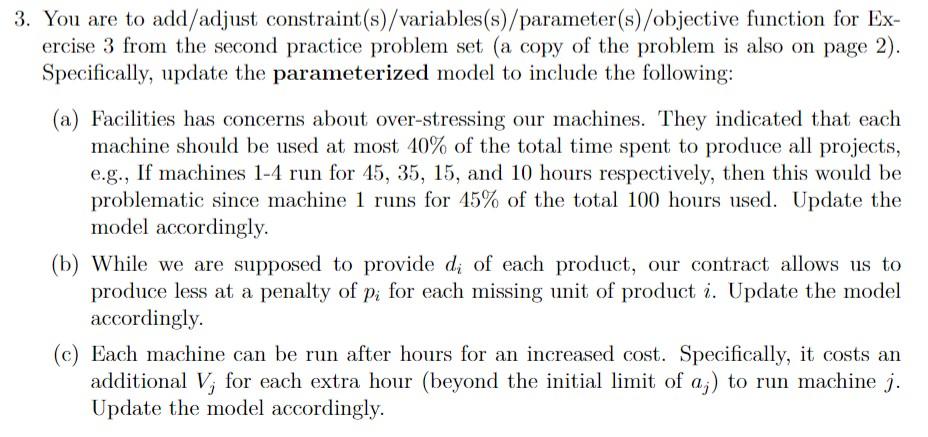

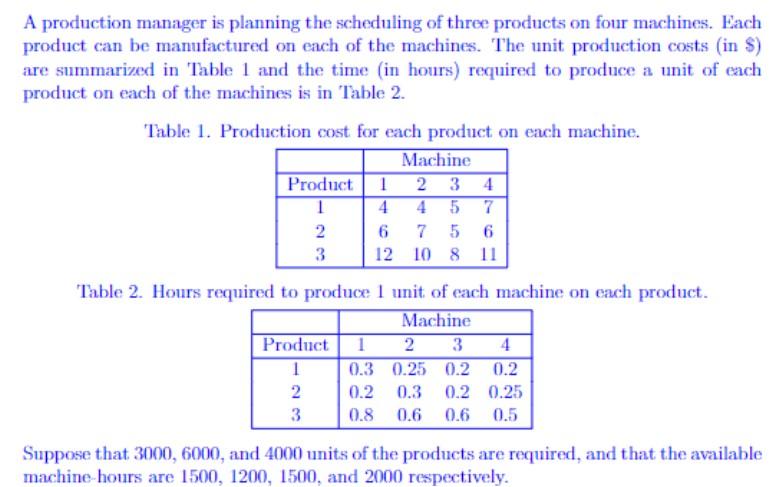

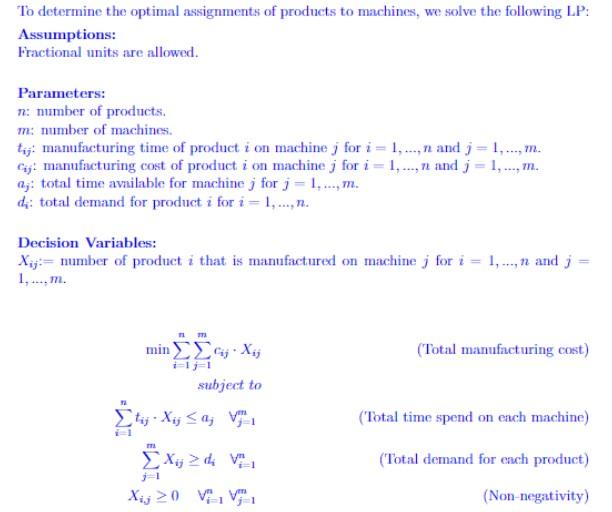

3. You are to add/adjust constraint(s)/variables(s)/parameter(s)/objective function for Ex- ercise 3 from the second practice problem set (a copy of the problem is also on page 2). Specifically, update the parameterized model to include the following: (a) Facilities has concerns about over-stressing our machines. They indicated that each machine should be used at most 40% of the total time spent to produce all projects, e.g., If machines 1-4 run for 45, 35, 15, and 10 hours respectively, then this would be problematic since machine 1 runs for 45% of the total 100 hours used. Update the model accordingly. (b) While we are supposed to provide di of each product, our contract allows us to produce less at a penalty of p; for each missing unit of product i. Update the model accordingly. (c) Each machine can be run after hours for an increased cost. Specifically, it costs an additional V; for each extra hour (beyond the initial limit of a;) to run machine j. Update the model accordingly. A production manager is planning the scheduling of three products on four machines. Each product can be manufactured on each of the machines. The unit production costs (in $) are summarized in Table 1 and the time (in hours) required to produce a unit of each product on each of the machines is in Table 2. Table 1. Production cost for each product on each machine. Machine Product 1 2 3 4 1 4 4 5 7 2 6 7 5 6 3 12 10 8 11 Table 2. Hours required to produce 1 unit of each machine on each product. Machine Product 1 2 3 4 1 0.3 0.25 0.2 0.2 2 0.2 0.3 0.2 0.25 3 0.8 0.6 0.6 0.5 Suppose that 3000, 6000, and 4000 units of the products are required, and that the available machine hours are 1500, 1200, 1500, and 2000 respectively. To determine the optimal assignments of products to machines, we solve the following LP: Assumptions: Fractional units are allowed. Parameters: : number of products. m: number of machines. tiji manufacturing time of product i on machine ; for i = 1, ..., n and j = 1, ..., m. Gyi manufacturing cost of product i on machine ; for i = 1, ..., n and j = 1,...,m. az: total time available for mnchine ; for j = 1,...,m. di: total demand for product i for i=1,..., n. Decision Variables: Xiy= number of product i that is manufactured on machine ; for i = 1,...,n and ; 1. ...m. min , ., (Total manufacturing cost) subject to X;

0 VV" (Non-negativity) 3. You are to add/adjust constraint(s)/variables(s)/parameter(s)/objective function for Ex- ercise 3 from the second practice problem set (a copy of the problem is also on page 2). Specifically, update the parameterized model to include the following: (a) Facilities has concerns about over-stressing our machines. They indicated that each machine should be used at most 40% of the total time spent to produce all projects, e.g., If machines 1-4 run for 45, 35, 15, and 10 hours respectively, then this would be problematic since machine 1 runs for 45% of the total 100 hours used. Update the model accordingly. (b) While we are supposed to provide di of each product, our contract allows us to produce less at a penalty of p; for each missing unit of product i. Update the model accordingly. (c) Each machine can be run after hours for an increased cost. Specifically, it costs an additional V; for each extra hour (beyond the initial limit of a;) to run machine j. Update the model accordingly. A production manager is planning the scheduling of three products on four machines. Each product can be manufactured on each of the machines. The unit production costs (in $) are summarized in Table 1 and the time (in hours) required to produce a unit of each product on each of the machines is in Table 2. Table 1. Production cost for each product on each machine. Machine Product 1 2 3 4 1 4 4 5 7 2 6 7 5 6 3 12 10 8 11 Table 2. Hours required to produce 1 unit of each machine on each product. Machine Product 1 2 3 4 1 0.3 0.25 0.2 0.2 2 0.2 0.3 0.2 0.25 3 0.8 0.6 0.6 0.5 Suppose that 3000, 6000, and 4000 units of the products are required, and that the available machine hours are 1500, 1200, 1500, and 2000 respectively. To determine the optimal assignments of products to machines, we solve the following LP: Assumptions: Fractional units are allowed. Parameters: : number of products. m: number of machines. tiji manufacturing time of product i on machine ; for i = 1, ..., n and j = 1, ..., m. Gyi manufacturing cost of product i on machine ; for i = 1, ..., n and j = 1,...,m. az: total time available for mnchine ; for j = 1,...,m. di: total demand for product i for i=1,..., n. Decision Variables: Xiy= number of product i that is manufactured on machine ; for i = 1,...,n and ; 1. ...m. min , ., (Total manufacturing cost) subject to X; 0 VV" (Non-negativity)