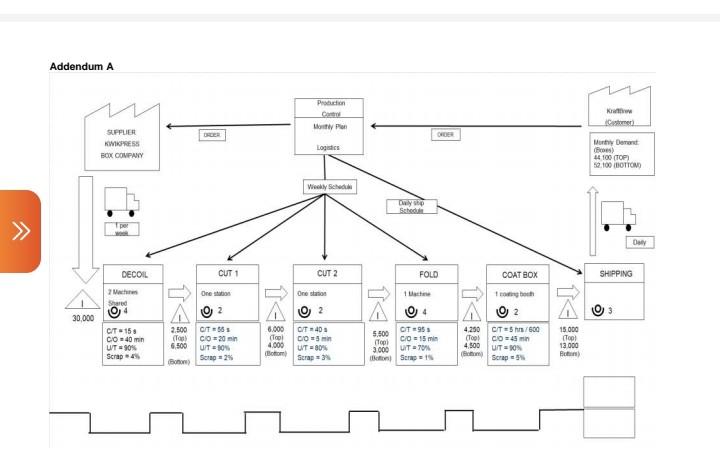

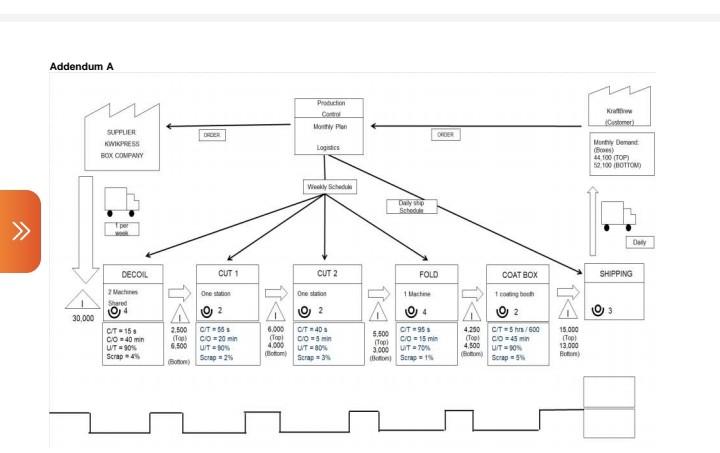

Question: 3.2 ? 3.3 ? 3.4 ? 3.5 ? >>> Addendum A 30,000 SUPPLIER KWIKPRESS BOX COMPANY per DECOIL 2 Mach Shared 04 C/T=158 C/O=40 min

3.2 ? 3.3 ? 3.4 ? 3.5 ?

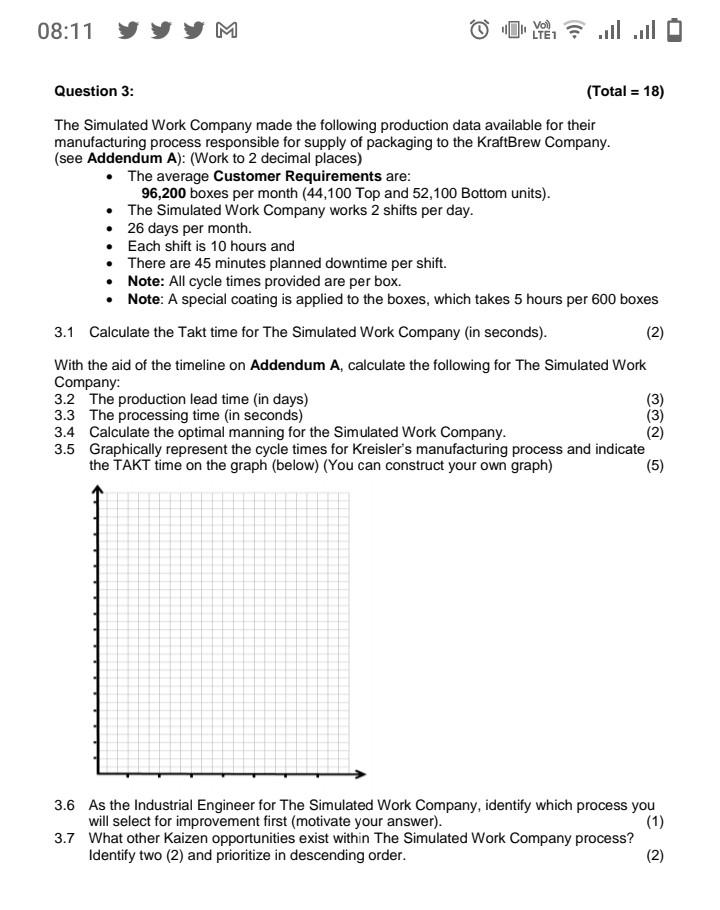

>>> Addendum A 30,000 SUPPLIER KWIKPRESS BOX COMPANY per DECOIL 2 Mach Shared 04 C/T=158 C/O=40 min L/T=90% Scrap-4% 2.500 (Top) 6,500 Boto) CUT 1 One station 0 C/T55 C/O=20 min U/T = 90% Scrap2% 6.000 (Top) 4.000 (Bottom) Production Cont Monthly Plan Logistics Weekly Sched CUT 2 One station 2 C/T = 40 s C/O=5 UT = 80% Scrap = 3% 5.500 (Top) 3,000 Boon Daily sp Schedule ORDER FOLD 1 Mache 4 CIT=95 C/O=15min UIT-70% Scrap = 1% 4,250 (Top) 4.500 (Foto) COAT BOX 1 coin both 2 C/T=5hrs/600 C/O = 45 m U/T = 90% Scrap 15.000 (Top) 13.000 Exton) Ka Castomer) Monty Demand (Boes) 44,100 (TOP) 52,100 (BOTTOM) SHIPPING 3 >>> Addendum A 30,000 SUPPLIER KWIKPRESS BOX COMPANY per DECOIL 2 Mach Shared 04 C/T=158 C/O=40 min L/T=90% Scrap-4% 2.500 (Top) 6,500 Boto) CUT 1 One station 0 C/T55 C/O=20 min U/T = 90% Scrap2% 6.000 (Top) 4.000 (Bottom) Production Cont Monthly Plan Logistics Weekly Sched CUT 2 One station 2 C/T = 40 s C/O=5 UT = 80% Scrap = 3% 5.500 (Top) 3,000 Boon Daily sp Schedule ORDER FOLD 1 Mache 4 CIT=95 C/O=15min UIT-70% Scrap = 1% 4,250 (Top) 4.500 (Foto) COAT BOX 1 coin both 2 C/T=5hrs/600 C/O = 45 m U/T = 90% Scrap 15.000 (Top) 13.000 Exton) Ka Castomer) Monty Demand (Boes) 44,100 (TOP) 52,100 (BOTTOM) SHIPPING 3 .... .... = " 08:11 y y M LTE1 Question 3: (Total = 18) The Simulated Work Company made the following production data available for their manufacturing process responsible for supply of packaging to the KraftBrew Company. (see Addendum A): (Work to 2 decimal places) The average Customer Requirements are: 96,200 boxes per month (44,100 Top and 52,100 Bottom units). The Simulated Work Company works 2 shifts per day. 26 days per month. Each shift is 10 hours and There are 45 minutes planned downtime per shift. Note: All cycle times provided are per box. Note: A special coating is applied to the boxes, which takes 5 hours per 600 boxes 3.1 Calculate the Takt time for The Simulated Work Company (in seconds). (2) With the aid of the timeline on Addendum A, calculate the following for The Simulated Work Company: 3.2 The production lead time (in days) 3.3 The processing time (in seconds) 3.4 Calculate the optimal manning for the Simulated Work Company. (3) (5) 3.5 Graphically represent the cycle times for Kreisler's manufacturing process and indicate the TAKT time on the graph (below) (You can construct your own graph) 3.6 As the Industrial Engineer for The Simulated Work Company, identify which process you will select for improvement first (motivate your answer). (1) 3.7 What other Kaizen opportunities exist within The Simulated Work Company process? Identify two (2) and prioritize in descending order. (2)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts