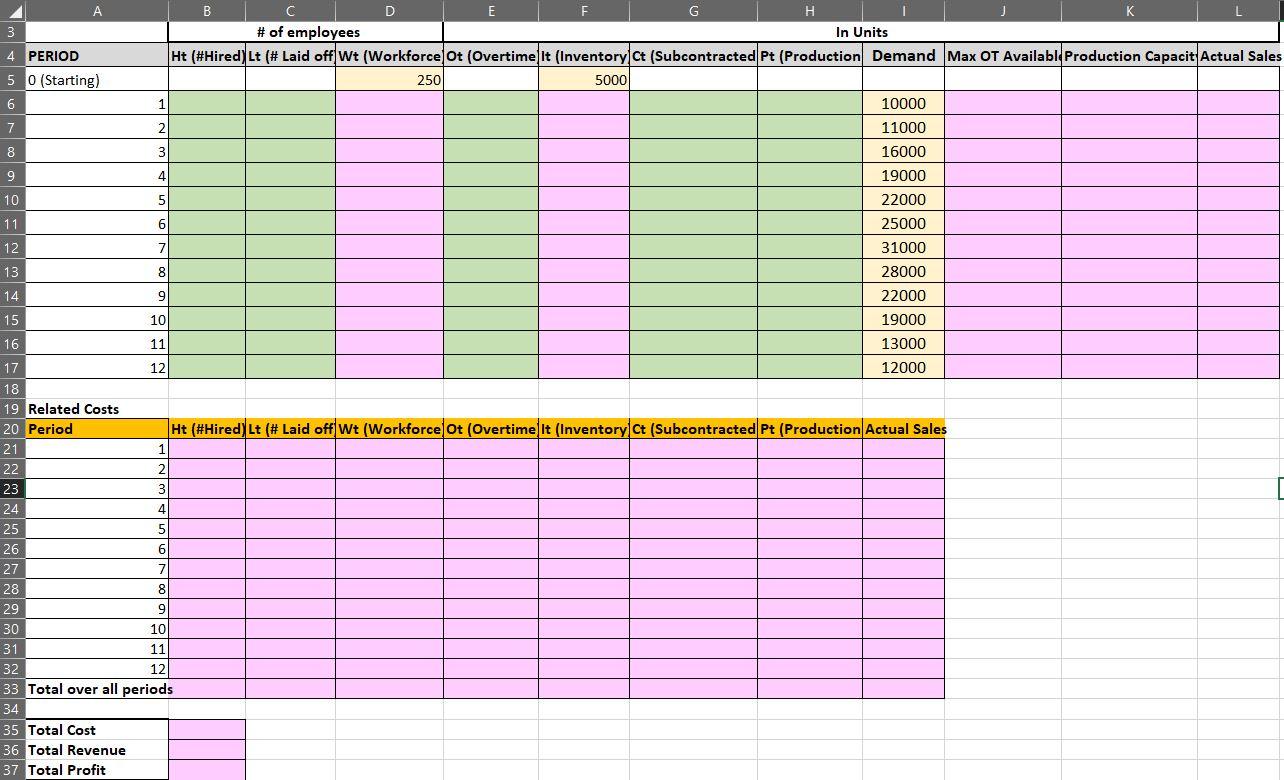

Question: use the info. below and Linear programming, to come up with the most optimal aggregate Production plan via EXCEL. you may need to set up

use the info. below and Linear programming, to come up with the most optimal aggregate Production plan via EXCEL.

you may need to set up constraints

| Costs | |

| Regular Time Labour | 15 |

| Overtime Labour | 22 |

| Subcontracting cost (per unit) | 74 |

| Inventory carrying cost (per unit per month) | 3 |

| Material cost (per unit) | 40 |

| Selling Price (per unit) | 125 |

| Hiring Cost (per new employee) | 1000 |

| Lay-off cost (per laid off employee) | 2000 |

| Starting Inventory | 5000 |

| Desired Ending Inventory | 5000 |

| Overtime Limit (number of units produced per employee) | 10 |

| Production Capacity (per employee per month) | 80 units |

| Starting Workforce | 250 workers |

| Labour hours per unit | 2 |

| MAX overtime per month per employee, HOURS | 20 |

| # of working days per month | 20 |

| # of hours per day | 8 |

3 4 PERIOD 5 0 (Starting) 6 7 8 9 A 10 11 12 13 14 15 16 1 2 3 35 Total Cost 36 Total Revenue 37 Total Profit 4 5 6 7 8 9 10 11 12 17 18 19 Related Costs 20 Period 21 22 23 24 25 26 27 28 29 30 31 32 33 Total over all periods 34 B D E C # of employees In Units Ht (#Hired) Lt (# Laid off) Wt (Workforce Ot (Overtime It (Inventory Ct (Subcontracted Pt (Production Demand Max OT Available Production Capacit Actual Sales 250 5000 F G H 10000 11000 16000 19000 22000 25000 31000 28000 22000 19000 13000 12000 K Ht (#Hired) Lt (# Laid off) Wt (Workforce) Ot (Overtime It (Inventory Ct (Subcontracted Pt (Production Actual Sales 1 2 3 4 5 6 7 8 9 10 11 12

Step by Step Solution

3.37 Rating (163 Votes )

There are 3 Steps involved in it

In order to create the most optimal aggregate production plan using the information provided and the linear programming approach in Excel several step... View full answer

Get step-by-step solutions from verified subject matter experts