Question: 4 0 2 Chapter 9 * Sourcing and procurement Figure 9 . 1 4 Supplier segments and policy considerations EASE STUDY 9 . 6 SRM

Chapter Sourcing and procurement

Figure Supplier segments and policy considerations

EASE STUDY

SRM at Eaton

Eaton Corporation is a $ billion diversified power management and technology manufacturer of over products as diverse as pumps and valves, cylinders, connectors, hoses and motors. The company has a programme under way to move from to some main suppliers of materials by consolidating spend with fewer suppliers, in particular suppliers that can help achieve best total costs see total cost of ownership in Section best service and quality. As a result, Eaton has recognised the need to focus on strategic suppliers see supplier segmentation in Section and be an attractive customer to those suppliers also see Section on customer of choice Criteria used for deciding which suppliers are strategic include:

they meet basic requirements of competitive pricing, quality and service standards and customer satisfaction;

they meet extended requirements such as supporting flexibility, complexity reduction and business continuity eg there is a basis for a longterm relationship;

they dedicate resources to the joint business relationship people process, technology, capacity and investments;

they grant access to brainpower and innovations and align to Eaton's strategic goals.

In the context of its supplier relationship management efforts, Eaton defines its procurement function to fundamentally be:

a relationship builder agent;

a change agent; and

a business process improvement agent.

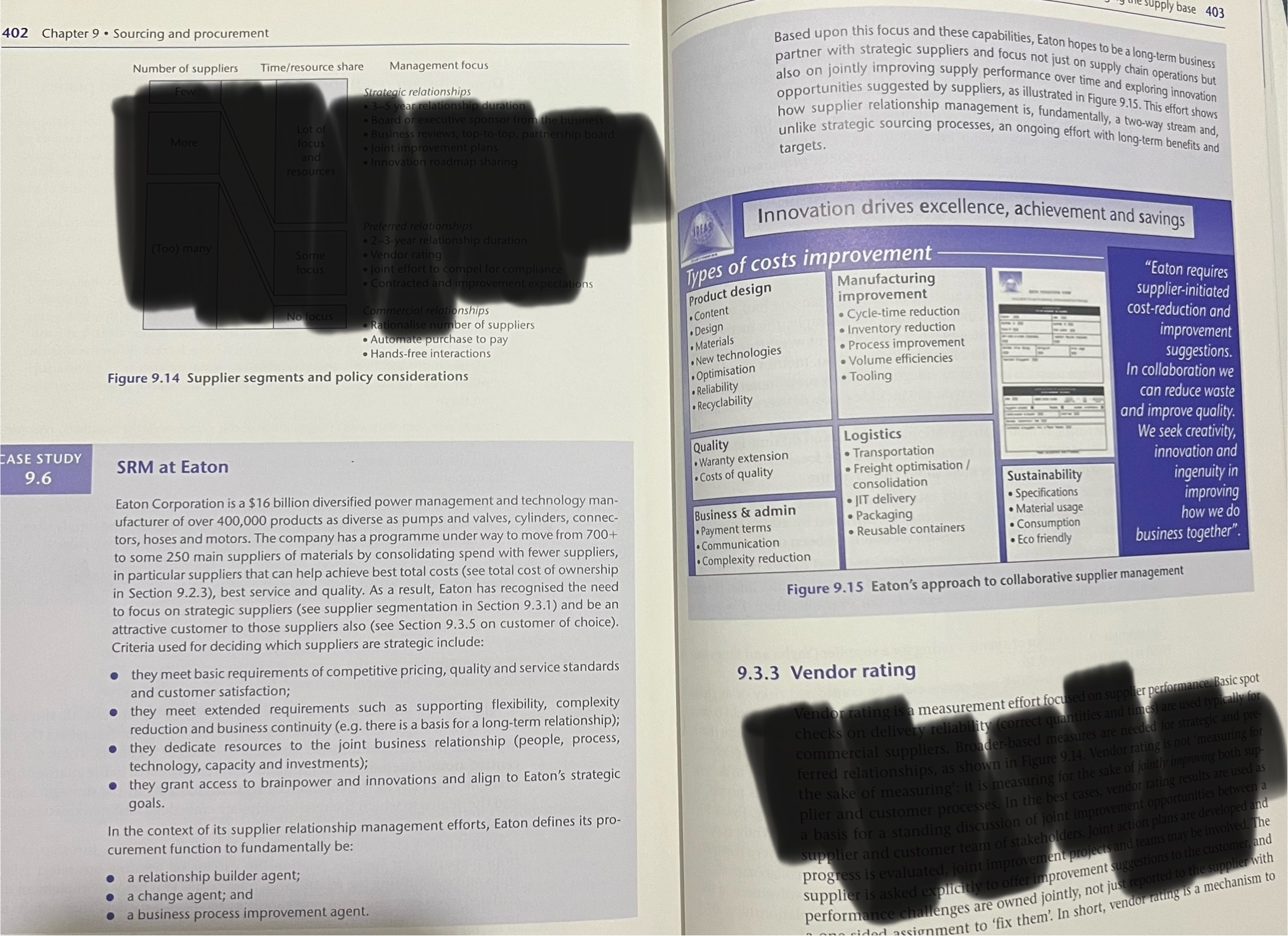

Based upon this focus and these capabilities, Eaton hopes to be a longterm business partner with strategic suppliers and focus not just on supply chain operations but also on jointly improving supply performance over time and exploring innovation opportunities suggested by suppliers, as illustrated in Figure This effort shows how supplier relationship management is fundamentally, a twoway stream and, unlike strategic sourcing processes, an ongoing effort with longterm benefits and targets.

product design

Content

Design

Materials

New technologies

Optimisation

Reliability

Recyclability

Quality

Waranty extension

Costs of quality

Business & admin

Payment terms

Communication

Complexity reduction

tableManufacturingimprovement Cycletime reduction Inventory reduction Process improvement Volume efficiencies Tooling

Logistics

Transportation

Freight optimisation consolidation

IT delivery

Packaging

Reusable containers

"Eaton requires

supplierinitiated

costreduction and

improvement

suggestions.

In collaboration we

can reduce waste

and improve quality.

We seek creativity,

innovation and ingenuity in improving

how we do

business together".

Figure Eaton's approach to collaborative supplier management

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock