Question: 4 0 DISCRETE - EVENTSYSTEM SIMULATION Example 2 . 4 : Simulation of an Order - Up - To - LeveI Inventory System Consider a

DISCRETEEVENTSYSTEM SIMULATION

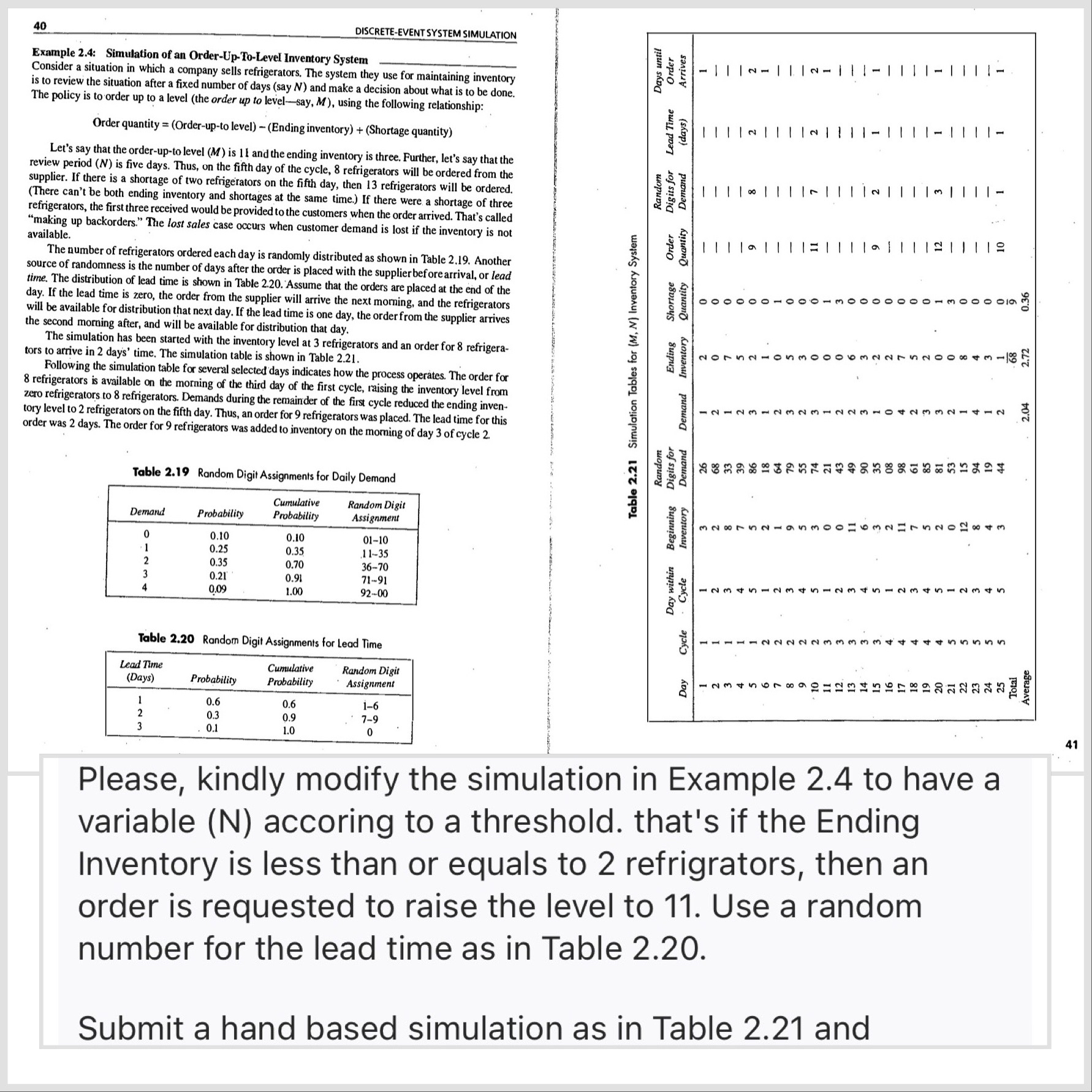

Example : Simulation of an OrderUpToLeveI Inventory System Consider a situation in which a company sells refrigerators. The system they use for maintaining inventory is to review the situation after a fixed number of days say and make a decision about what is to be done. The policy is to order up to a level the order up to levelsay, using the following relationship:

Order quantity level inventory quantity

Let's say that the orderupto level is and the ending inventory is three. Further, let's say that the review period is five days. Thus, on the fifth day of the cycle, refrigerators will be ordered from the supplier. If there is a shortage of two refrigerators on the fifth day, then refrigerators will be ordered. There can't be both ending inventory and shortages at the same time. If there were a shortage of three refrigerators, the first three received would be provided to the customers when the order arrived. That's called "making up backorders." The lost sales case occurs when customer demand is lost if the inventory is not available.

The number of refrigerators ordered each day is randomly distributed as shown in Table Another source of randomness is the number of days after the order is placed with the supplierbef ore arrival, or lead time. The distribution of lead time is shown in Table Assume that the orders are placed at the end of the day. If the lead time is zero, the order from the supplier will arrive the next morning, and the refrigerators will be available for distribution that next day. If the lead time is one day, the order from the supplier arrives the second morning after, and will be available for distribution that day.

The simulation has been started with the inventory level at refrigerators and an order for refrigerators to arrive in days' time. The simulation table is shown in Table

Following the simulation table for several selected days indicates how the process operates. The order for refrigerators is available on the morning of the third day of the first cycle, raising the inventory level from zero refrigerators to refrigerators. Demands during the remainder of the first cycle reduced the ending inventory level to refrigerators on the fifth day. Thus, an order for refrigerators was placed. The lead time for this order was days. The order for refrigerators was added to inventory on the morning of day of cycle

Table Random Digit Assignments for Daily Demand

tableDemandProbability,tableCumulativeProbabilitytableRandom DigitAssignment

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock