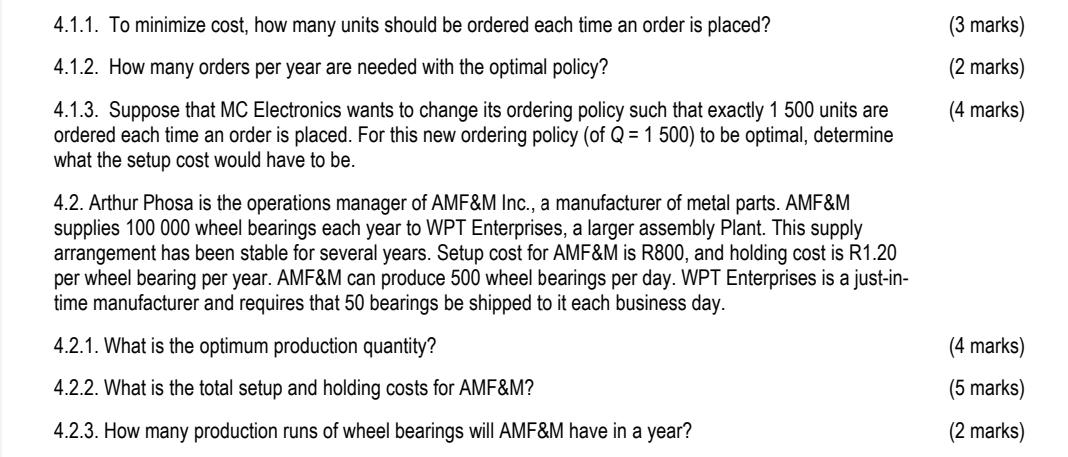

Question: 4 . 1 . 1 . To minimize cost, how many units should be ordered each time an order is placed? ( 3 marks )

To minimize cost, how many units should be ordered each time an order is placed?

marks

How many orders per year are needed with the optimal policy?

marks

Suppose that MC Electronics wants to change its ordering policy such that exactly units are

marks

ordered each time an order is placed. For this new ordering policy of to be optimal, determine what the setup cost would have to be

Arthur Phosa is the operations manager of AMF&M Inc., a manufacturer of metal parts. AMF&M supplies wheel bearings each year to WPT Enterprises, a larger assembly Plant. This supply arrangement has been stable for several years. Setup cost for AMF&M is R and holding cost is R per wheel bearing per year. AMF&M can produce wheel bearings per day. WPT Enterprises is a justintime manufacturer and requires that bearings be shipped to it each business day.

What is the optimum production quantity?

marks

What is the total setup and holding costs for AMF&M

marks

How many production runs of wheel bearings will AMF&M have in a year?

marks

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock