Question: * 4 . 1 . 1 Workpiece Material: 6 0 6 1 Aluminum * 4 . 1 . 2 The radial depth of cut: 0

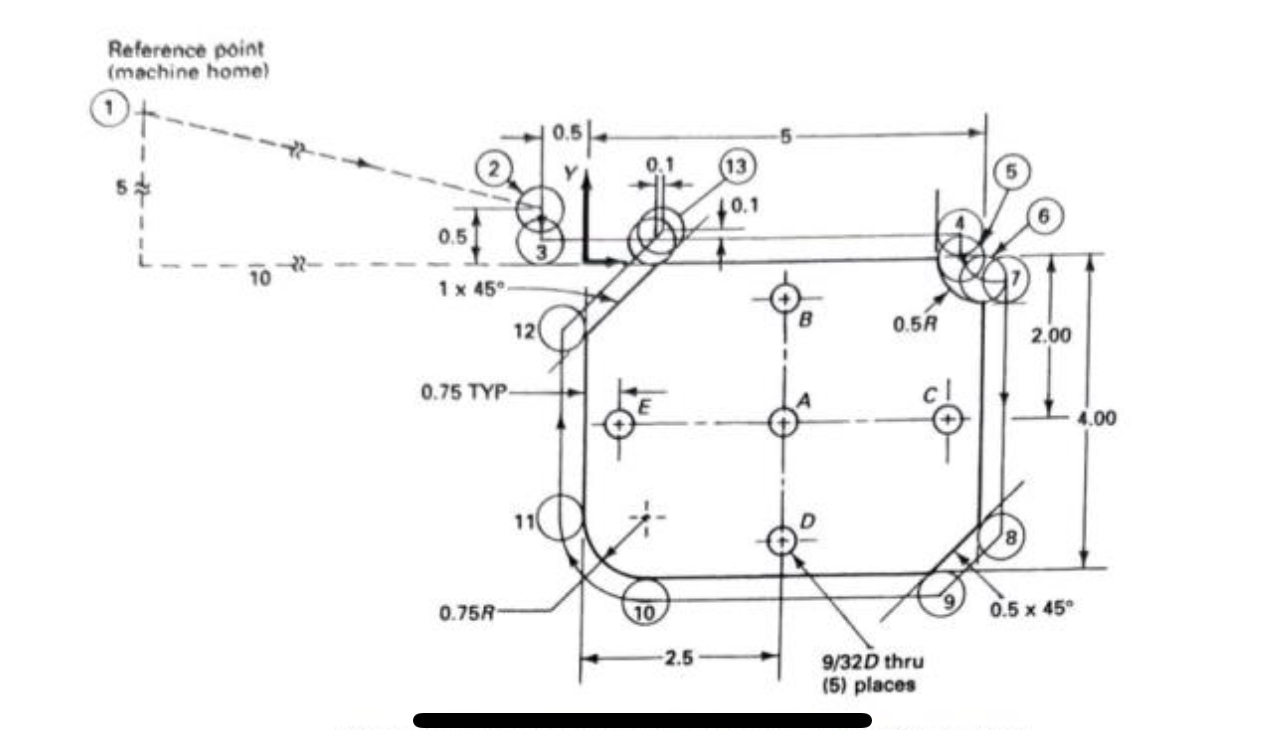

Workpiece Material: Aluminum The radial depth of cut: Use Haas PN as the end mill for all milling operations data sheet and speed and feed tables provided The Part Reference Zero PRZ is: Part #: indicated on the drawing as the center of the part Part #: in dictated on the drawing as the upper left corner of the part, not the "Machine Home" position point Use Haas PN as the end mill for all milling operations data sheet and speed and feed tables provided Assume Aluminum is in VDI Group Part production rate is more important that surface finish. Use fz factor to adjust for chip thinning Instructions Use the part drawing shown below to create a Gcode part program. For Exercise and Exercise below write a GCode part program which incorporates cutter compensation: G G G Circular Interpolations: For G and G useI,JK syntax, not R syntax Insert or delete rows in the table as required to complete the assignment Mill the periphery of workpiece Use end mill specification sheet provided Tool # Create a new point to follow point and ramp off cutter compensation Use your "Speed and Feed Calculator" Excel file from Lab # to aid in calculating the speed and feed rates required Perform sample calculations in section below. This allows partial credit to be given if the solution is not correct Position a drill bit Tool #; No specifications provided over the holes but do not drill them Rapid to above the part Use G and G as desired to position the drill bit above the holes Cutter compensation is not used for this drilling operation Use the GCode table, below in section to record your GCode. To the right of your GCode, record the function of every word within the block.Reference point machine home

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock