Question: 4 5 Tutorial 4 Done 6 . You are appointed as a junior metallurgist in the Anglo - American plant dealing with the recovery of

Tutorial

Done

You are appointed as a junior metallurgist in the AngloAmerican plant dealing with the recovery of PGMs in the Bushveld igneous complex. After their prospective survey, the plant geologists confirmed that the plant would be dealing with a seam of mixed sulfide and oxide ores. It should be noted that from their survey, all the PGMs are trapped in the sulphide matrix made of Chalcopyrite, pyrrhotite, and pentlandite, and the seam has the high grade of and Therefore, there is no need for concentration. You are selected as a team leader to coordinate and proposed a clear chain value route to recover PGMs and principal elements such as and as the byproducts using the hydrometallurgical route. After the study, you and your team proposed four scenarios to recover and

The first consists of Roasting Leaching acid Clarification Fe removal Purification solvent extraction: LIX and LIX Metal recovery electrowinning

The second consists of Direct leaching acid or base: please define conditions Clarification Fe removal Purification activated carbon Metal recovery cementation and precipitation

The third consists of Melting Reduction leaching acid Purification activated carbon Metal recovery cementation and precipitation

The fourth consist of Melting reduction Metal recovery electrorefining of copper only

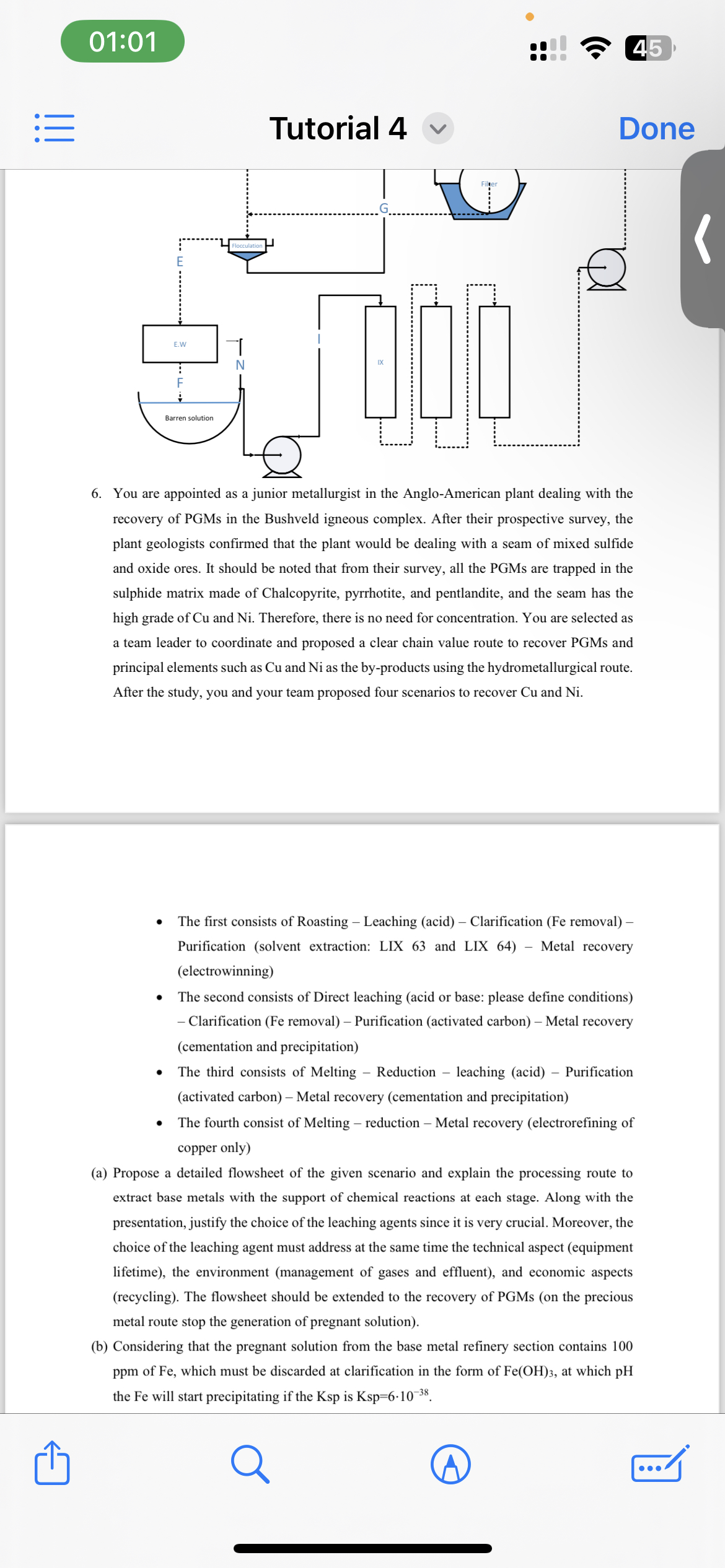

a Propose a detailed flowsheet of the given scenario and explain the processing route to extract base metals with the support of chemical reactions at each stage. Along with the presentation, justify the choice of the leaching agents since it is very crucial. Moreover, the choice of the leaching agent must address at the same time the technical aspect equipment lifetime the environment management of gases and effluent and economic aspects recycling The flowsheet should be extended to the recovery of PGMs on the precious metal route stop the generation of pregnant solution

b Considering that the pregnant solution from the base metal refinery section contains ppm of which must be discarded at clarification in the form of at which the Fe will start precipitating if the is

uarr

Q

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock