Question: 4. (a) How does a cross-docking warehouse let Walmart move inventory rapidly from manufacturers to stores? (b) A common technique in warehouse location is the

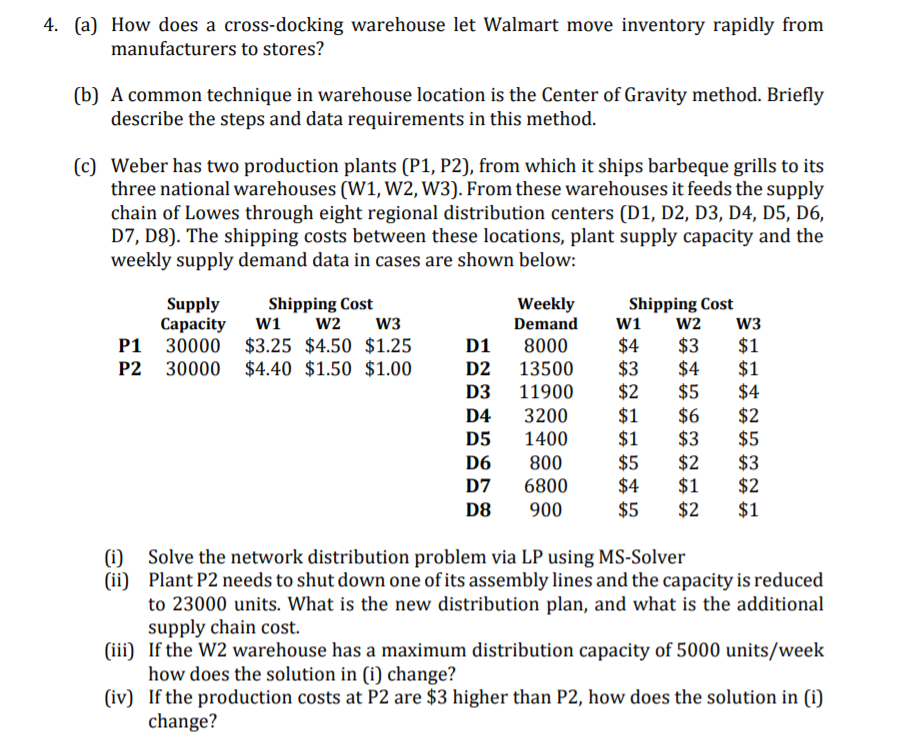

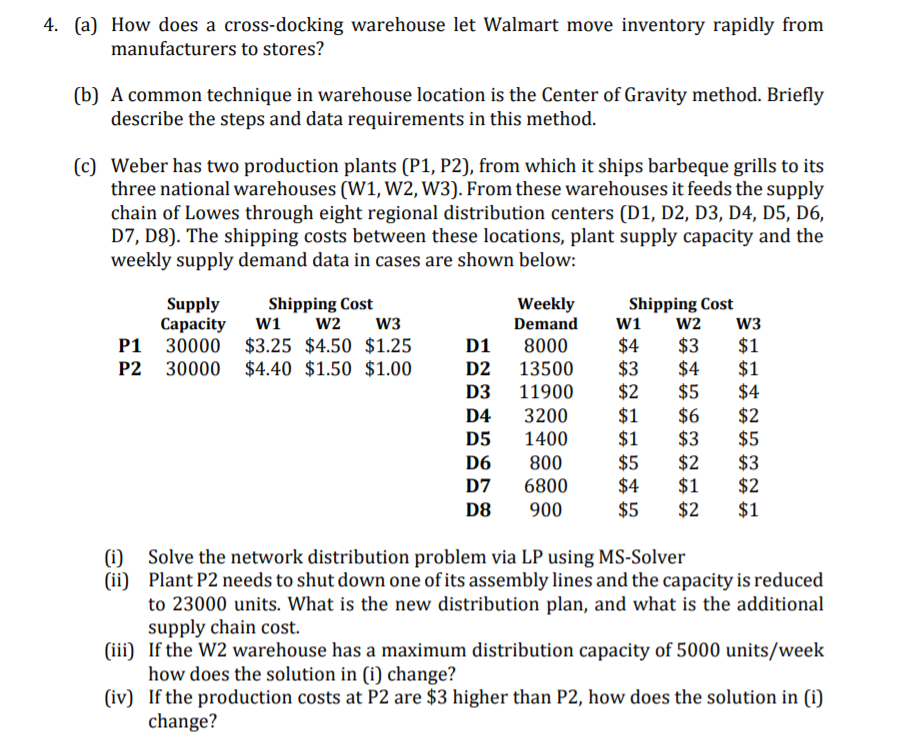

4. (a) How does a cross-docking warehouse let Walmart move inventory rapidly from manufacturers to stores? (b) A common technique in warehouse location is the Center of Gravity method. Briefly describe the steps and data requirements in this method. (C) Weber has two production plants (P1, P2), from which it ships barbeque grills to its three national warehouses (W1, W2, W3). From these warehouses it feeds the supply chain of Lowes through eight regional distribution centers (D1, D2, D3, D4, D5, D6, D7, D8). The shipping costs between these locations, plant supply capacity and the weekly supply demand data in cases are shown below: Supply Capacity P1 30000 P2 30000 Shipping Cost W1 W2 W3 $3.25 $4.50 $1.25 $4.40 $1.50 $1.00 D1 D2 D3 D4 D5 D6 D7 D8 Weekly Demand 8000 13500 11900 3200 1400 800 6800 900 Shipping Cost W1 W2 W3 $4 $3 $1 $3 $4 $1 $2 $5 $4 $1 $6 $2 $1 $3 $5 $5 $2 $3 $4 $1 $5 $2 $1 $2 (i) Solve the network distribution problem via LP using MS-Solver (ii) Plant P2 needs to shut down one of its assembly lines and the capacity is reduced to 23000 units. What is the new distribution plan, and what is the additional supply chain cost. (iii) If the W2 warehouse has a maximum distribution capacity of 5000 units/week how does the solution in (i) change? (iv) If the production costs at P2 are $3 higher than P2, how does the solution in (i) change? 4. (a) How does a cross-docking warehouse let Walmart move inventory rapidly from manufacturers to stores? (b) A common technique in warehouse location is the Center of Gravity method. Briefly describe the steps and data requirements in this method. (C) Weber has two production plants (P1, P2), from which it ships barbeque grills to its three national warehouses (W1, W2, W3). From these warehouses it feeds the supply chain of Lowes through eight regional distribution centers (D1, D2, D3, D4, D5, D6, D7, D8). The shipping costs between these locations, plant supply capacity and the weekly supply demand data in cases are shown below: Supply Capacity P1 30000 P2 30000 Shipping Cost W1 W2 W3 $3.25 $4.50 $1.25 $4.40 $1.50 $1.00 D1 D2 D3 D4 D5 D6 D7 D8 Weekly Demand 8000 13500 11900 3200 1400 800 6800 900 Shipping Cost W1 W2 W3 $4 $3 $1 $3 $4 $1 $2 $5 $4 $1 $6 $2 $1 $3 $5 $5 $2 $3 $4 $1 $5 $2 $1 $2 (i) Solve the network distribution problem via LP using MS-Solver (ii) Plant P2 needs to shut down one of its assembly lines and the capacity is reduced to 23000 units. What is the new distribution plan, and what is the additional supply chain cost. (iii) If the W2 warehouse has a maximum distribution capacity of 5000 units/week how does the solution in (i) change? (iv) If the production costs at P2 are $3 higher than P2, how does the solution in (i) change