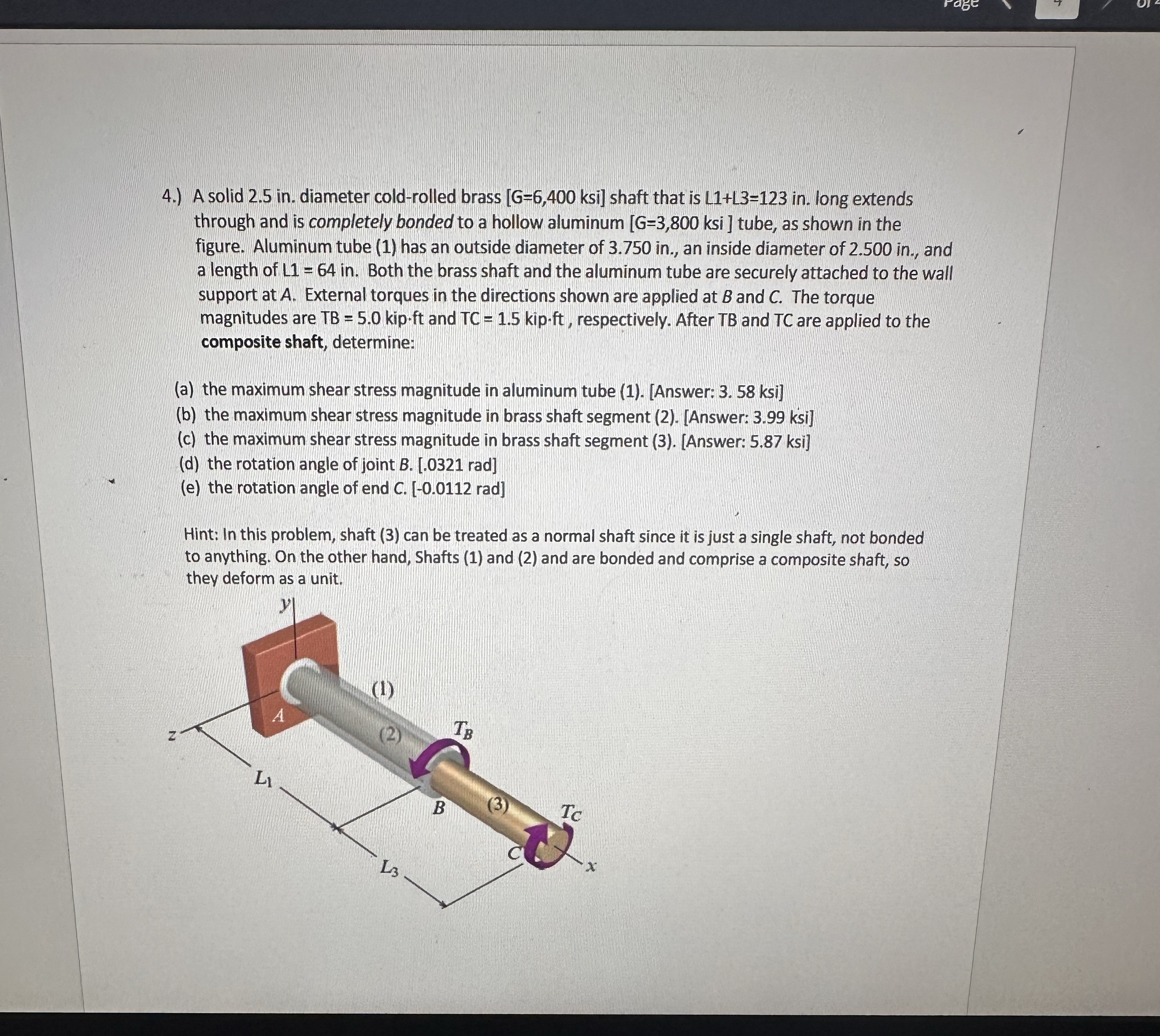

Question: 4 . ) A solid 2 . 5 in . diameter cold - rolled brass G = 6 , 4 0 0 ksi shaft that

A solid in diameter coldrolled brass ksi shaft that is long extends

through and is completely bonded to a hollow aluminum G ksi tube, as shown in the

figure. Aluminum tube has an outside diameter of in an inside diameter of in and

a length of Both the brass shaft and the aluminum tube are securely attached to the wall

support at External torques in the directions shown are applied at and The torque

magnitudes are kip and kip respectively. After and TC are applied to the

composite shaft, determine:

a the maximum shear stress magnitude in aluminum tube Answer: ksi

b the maximum shear stress magnitude in brass shaft segment Answer: ksi

c the maximum shear stress magnitude in brass shaft segment Answer: ksi

d the rotation angle of joint B rad

e the rotation angle of end rad

Hint: In this problem, shaft can be treated as a normal shaft since it is just a single shaft, not bonded

to anything. On the other hand, Shafts and and are bonded and comprise a composite shaft, so

they deform as a unit.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock