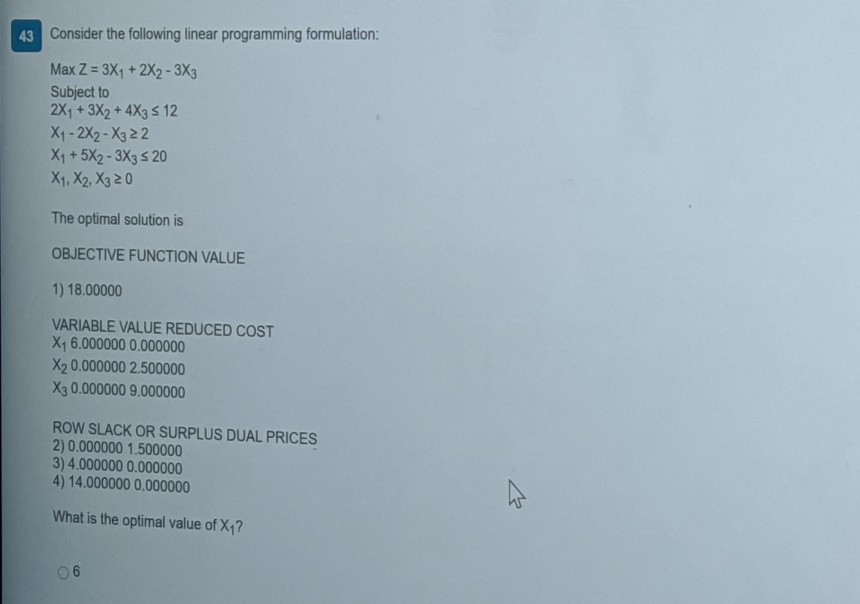

Question: 43 Consider the following linear programming formulation: Max Z = 3X1 + 2X2 - 3X3 Subject to 2X1 +3X2 + 4X3 12 X, 2X2 X3

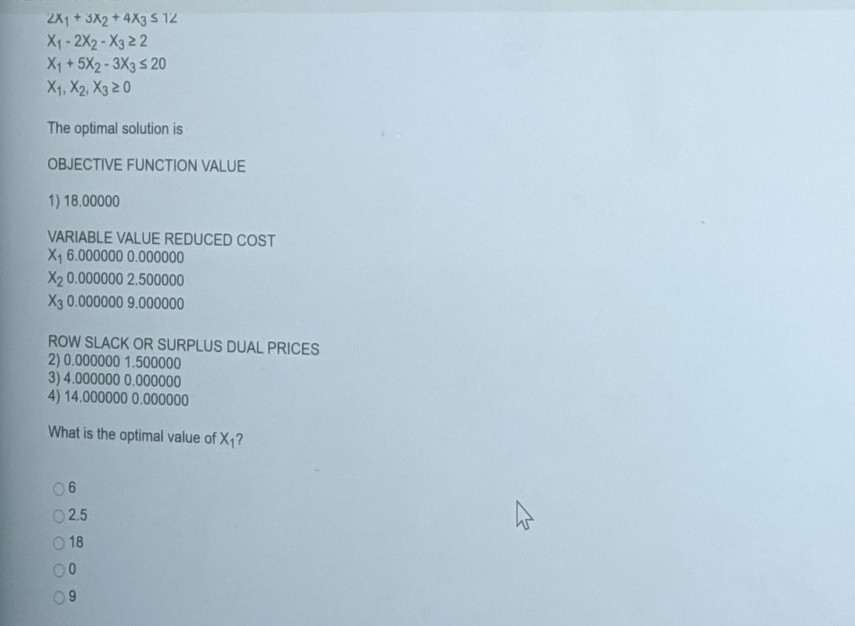

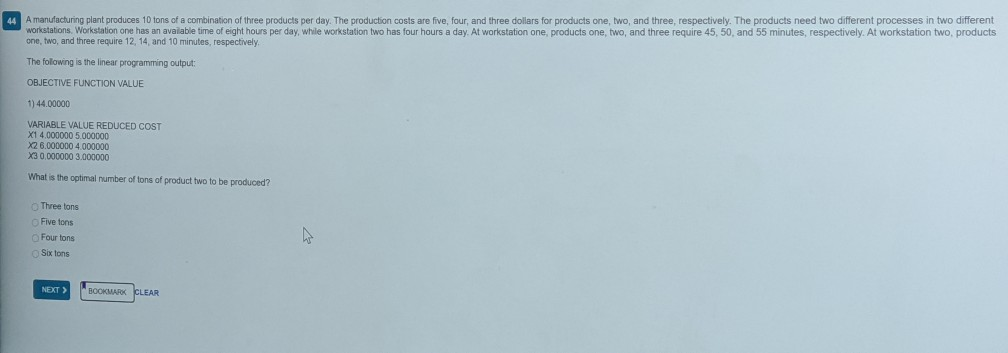

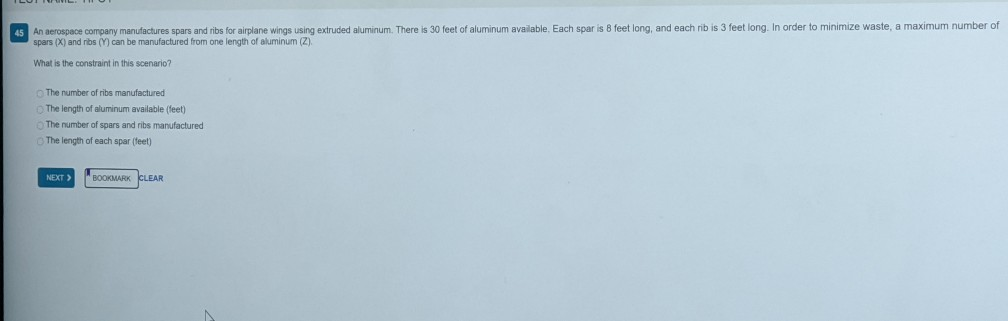

43 Consider the following linear programming formulation: Max Z = 3X1 + 2X2 - 3X3 Subject to 2X1 +3X2 + 4X3 12 X, 2X2 X3 22 X1 +5X2 - 3X3 = 20 X1, X2, X20 The optimal solution is OBJECTIVE FUNCTION VALUE 1) 18.00000 VARIABLE VALUE REDUCED COST X16.000000 0.000000 X2 0.000000 2.500000 X3 0.000000 9.000000 ROW SLACK OR SURPLUS DUAL PRICES 2) 0.000000 1.500000 3) 4.000000 0.000000 4) 14.000000 0.000000 What is the optimal value of X1? 6 2X1 + 3X2 + 4X3 S 12 X - 2X2 - X 22 X1 +5X2 - 3X3 = 20 X1, X2, X3 20 The optimal solution is OBJECTIVE FUNCTION VALUE 1) 18.00000 VARIABLE VALUE REDUCED COST X16.000000 0.000000 X2 0.000000 2.500000 X3 0.000000 9.000000 ROW SLACK OR SURPLUS DUAL PRICES 2) 0.000000 1.500000 3)4.000000 0.000000 4) 14.000000 0.000000 What is the optimal value of X1? 6 2.5 18 00 44 A manufacturing plant produces 10 tons of a combination of three products per day. The production costs are five, four, and three dollars for products one, two, and three, respectively. The products need two different processes in two different workstations. Workstation one has an available time of eight hours per day, while workstation two has four hours a day. At workstation one, products one, two, and three require 45, 50, and 55 minutes, respectively. At workstation two, products one, two, and three require 12, 14, and 10 minutes, respectively, The following is the linear programming output: OBJECTIVE FUNCTION VALUE 1) 44.00000 VARIABLE VALUE REDUCED COST X1 4.000000 5.000000 X26.000000 4.000000 X3 0,000000 3.000000 What is the optimal number of tons of product two to be produced? Three tons Five tons Four tons Six tons NEXT > BOOKMARK CLEAR An aerospace company manufactures spars and ribs for airplane wings using extruded aluminum. There is 30 feet of aluminum available. Each spar is 8 feet long, and each rib is 3 feet long. In order to minimize waste, a maximum number of spars (X) and ribs (1) can be manufactured from one length of aluminum (Z). What is the constraint in this scenario? The number of ribs manufactured The length of aluminum available (feet) The number of spars and ribs manufactured The length of each spar (feet) NEXT > BOOKMARK CLEAR

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock