Question: ( 5 0 marks ) A multistage fixed bed catalytic reactor was to be designed for the dehydrogenation of ethylbenzene ( 5 0 marks )

marks A multistage fixed bed catalytic reactor was to be designed for the dehydrogenation of ethylbenzene marks A multistage fixed bed catalytic reactor was to be designed for the dehydrogenation

of ethylbenzene into styrene using excess steam to control the reaction

temperature. The goal is to reach percent conversion of ethylbenzene, using a multistage

system if necessary. A new catalyst has been developed that allows operation at temperatures as

high as Assume that the pseudohomogeneous onedimensional plug flow model is valid,

and that each stage operates isobarically.

a If the reactor operates adiabatically, how many stages would be required in order to achieve

the target conversion with the new catalyst? Assume that the outlet temperature from each

stage is greater than the equilibrium temperature. List the outlet fractional conversion

and operating temperature for each stage. The graph provided on the next page may be

helpful.

b Assuming conversion is obtained in the first stage of this process, how much catalyst

would be required for this stage? Use a step size of for fractional conversion for your

numerical integration.

c If the Thiele modulus : for the catalyst particles in part b was equal to how much

extra catalyst in would be needed relative to your answer in part b

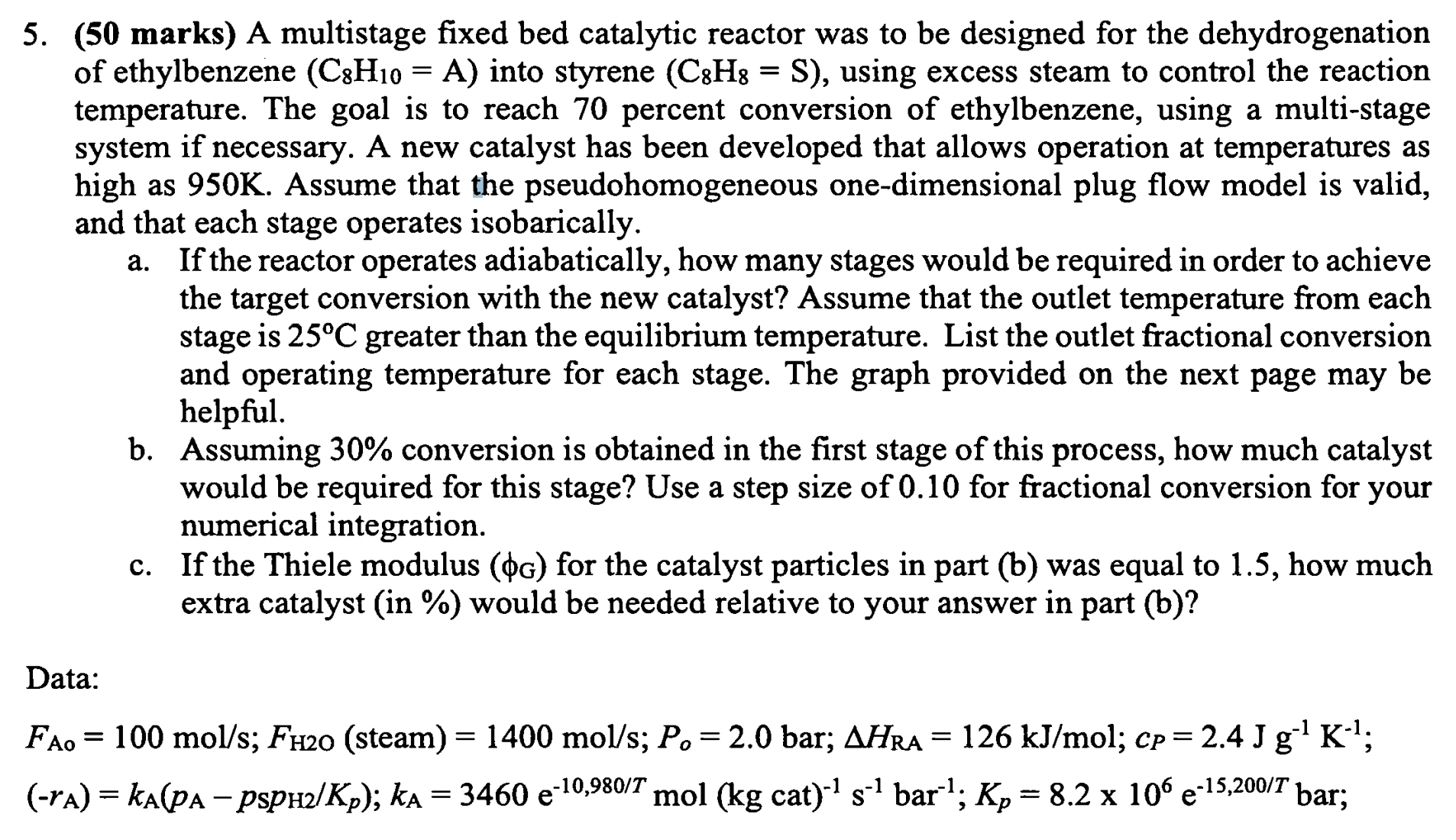

Data:

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock