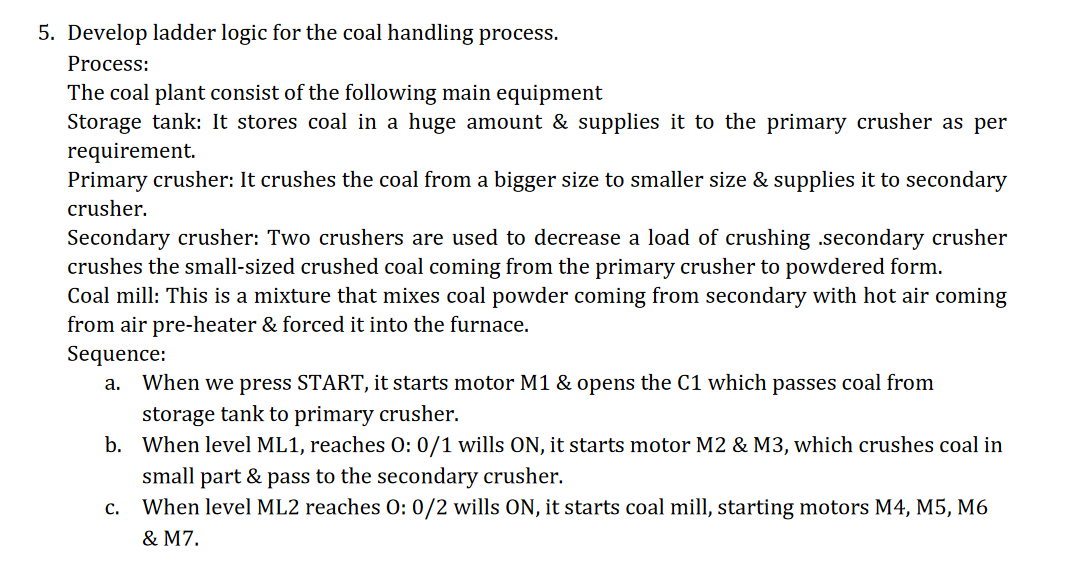

Question: 5 . Develop ladder logic for the coal handling process. Using PLC Programmble logic controller Process: The coal plant consist of the following main equipment

Develop ladder logic for the coal handling process. Using PLC Programmble logic controller

Process:

The coal plant consist of the following main equipment

Storage tank: It stores coal in a huge amount & supplies it to the primary crusher as per requirement.

Primary crusher: It crushes the coal from a bigger size to smaller size & supplies it to secondary crusher.

Secondary crusher: Two crushers are used to decrease a load of crushing secondary crusher crushes the smallsized crushed coal coming from the primary crusher to powdered form.

Coal mill: This is a mixture that mixes coal powder coming from secondary with hot air coming from air preheater & forced it into the furnace.

Sequence:

a When we press START, it starts motor M& opens the C which passes coal from storage tank to primary crusher.

b When level ML reaches : wills ON it starts motor M& M which crushes coal in small part & pass to the secondary crusher.

c When level ML reaches O: wills ON it starts coal mill, starting motors M M M& M

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock