Question: 5.21 Plasma spray-coating processes are often used to provide surface protection for materials exposed to hostile environments, which induce degradation through factors such as wear,

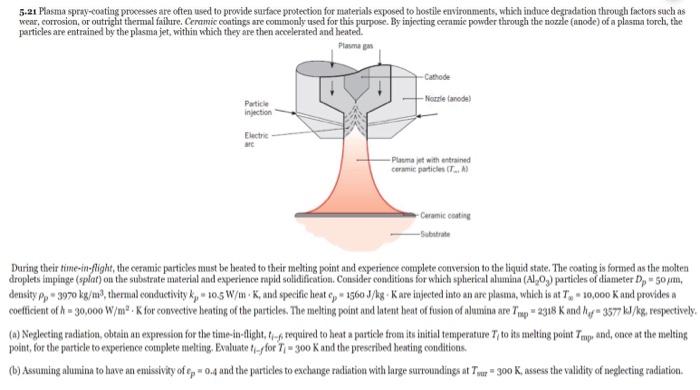

5.21 Plasma spray-coating processes are often used to provide surface protection for materials exposed to hostile environments, which induce degradation through factors such as wear, corrosion, or outright thermal failure. Ceranic contings are commonly used for this purpose. By injectiag ceramie powder through the nozde (anode) of a plasma torch, the particles are entrained by the plasma jet, within which they are then accelerated and heated. During their time-in-flight, the ceramic particles must be beated to their melting point and experience complete cotrersion to the liquid state. The coating is formed as the moltea droplets impinge (spiat) on the substrate material and experience mapid solidification. Consider conditions for which spherical ahimina (A2O3) particles of diameter Dp = 5m, deasity =3970kg/m3, thernal eoaductivity kp=10.5W/mK, and specific heat cp=1560J/kgK are injected iato an are plasma, which is at Tw=10,000K and provides a coefficient of h=30,000W/m2. K for convective beating of the particles. The melting point and latent beat of fusion of alumina are T1ap=2318K and hy = 3577kJ/kg, resjectively. (a) Neglecting radiation, obtain an expression for the time-ia-tlight, ti6 required to heat a patticle from its initial temperature Tj to its melting poiat Taip, and, oace at the melting point, for the particle to expericnce cotmplete melting. Evaluate tif for Ti=300K and the procribed heating conditions. (b) Assuming alumina to have an emissivity of p=0.4 and the particles to exchange radiation with large surroundings at Tmur=300K, assess the validity of neglecting radiation

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts