Question: 5-24 Forecasting resource capacity using a TDABC system Western Mechanical produces three products (Sequence, Forward, and Revolution) that are used in the heavy manufacturing industry.

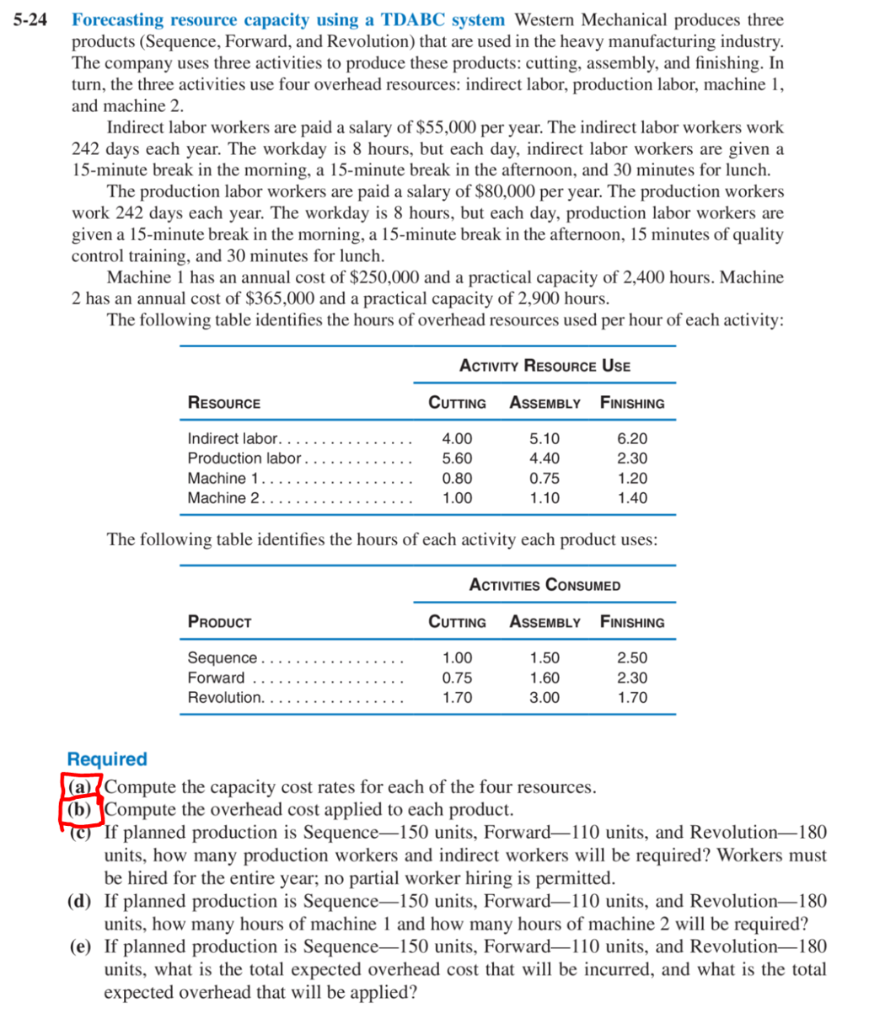

5-24 Forecasting resource capacity using a TDABC system Western Mechanical produces three products (Sequence, Forward, and Revolution) that are used in the heavy manufacturing industry. The company uses three activities to produce these products: cutting, assembly, and finishing. In turn, the three activities use four overhead resources: indirect labor, production labor, machine 1, and machine 2. Indirect labor workers are paid a salary of $55,000 per year. The indirect labor workers work 242 days each year. The workday is 8 hours, but each day, indirect labor workers are given a 15-minute break in the morning, a 15-minute break in the afternoon, and 30 minutes for lunch. The production labor workers are paid a salary of $80,000 per year. The production workers work 242 days each year. The workday is 8 hours, but each day, production labor workers are given a 15-minute break in the morning, a 15-minute break in the afternoon, 15 minutes of quality control training, and 30 minutes for lunch. Machine 1 has an annual cost of $250,000 and a practical capacity of 2,400 hours. Machine 2 has an annual cost of $365,000 and a practical capacity of 2,900 hours. The following table identifies the hours of overhead resources used per hour of each activity: ACTIVITY RESOURCE USE RESOURCE CUTTING ASSEMBLY FINISHING Indirect labor. Production labor Machine 1. Machine 2 4.00 5.60 0.80 1.00 5.10 4.40 0.75 1.10 6.20 2.30 1.20 1.40 The following table identifies the hours of each activity each product uses: ACTIVITIES CONSUMED PRODUCT CUTTING ASSEMBLY FINISHING Sequence Forward Revolution. 1.00 0.75 1.70 1.50 1.60 3.00 2.50 2.30 1.70 Required (a) Compute the capacity cost rates for each of the four resources. [(b) Compute the overhead cost applied to each product. TC) If planned production is Sequence150 units, Forward110 units, and Revolution180 units, how many production workers and indirect workers will be required? Workers must be hired for the entire year, no partial worker hiring is permitted. (d) If planned production is Sequence150 units, Forward110 units, and Revolution180 units, how many hours of machine 1 and how many hours of machine 2 will be required? (e) If planned production is Sequence150 units, Forward110 units, and Revolution180 units, what is the total expected overhead cost that will be incurred, and what is the total expected overhead that will be applied? 5-24 Forecasting resource capacity using a TDABC system Western Mechanical produces three products (Sequence, Forward, and Revolution) that are used in the heavy manufacturing industry. The company uses three activities to produce these products: cutting, assembly, and finishing. In turn, the three activities use four overhead resources: indirect labor, production labor, machine 1, and machine 2. Indirect labor workers are paid a salary of $55,000 per year. The indirect labor workers work 242 days each year. The workday is 8 hours, but each day, indirect labor workers are given a 15-minute break in the morning, a 15-minute break in the afternoon, and 30 minutes for lunch. The production labor workers are paid a salary of $80,000 per year. The production workers work 242 days each year. The workday is 8 hours, but each day, production labor workers are given a 15-minute break in the morning, a 15-minute break in the afternoon, 15 minutes of quality control training, and 30 minutes for lunch. Machine 1 has an annual cost of $250,000 and a practical capacity of 2,400 hours. Machine 2 has an annual cost of $365,000 and a practical capacity of 2,900 hours. The following table identifies the hours of overhead resources used per hour of each activity: ACTIVITY RESOURCE USE RESOURCE CUTTING ASSEMBLY FINISHING Indirect labor. Production labor Machine 1. Machine 2 4.00 5.60 0.80 1.00 5.10 4.40 0.75 1.10 6.20 2.30 1.20 1.40 The following table identifies the hours of each activity each product uses: ACTIVITIES CONSUMED PRODUCT CUTTING ASSEMBLY FINISHING Sequence Forward Revolution. 1.00 0.75 1.70 1.50 1.60 3.00 2.50 2.30 1.70 Required (a) Compute the capacity cost rates for each of the four resources. [(b) Compute the overhead cost applied to each product. TC) If planned production is Sequence150 units, Forward110 units, and Revolution180 units, how many production workers and indirect workers will be required? Workers must be hired for the entire year, no partial worker hiring is permitted. (d) If planned production is Sequence150 units, Forward110 units, and Revolution180 units, how many hours of machine 1 and how many hours of machine 2 will be required? (e) If planned production is Sequence150 units, Forward110 units, and Revolution180 units, what is the total expected overhead cost that will be incurred, and what is the total expected overhead that will be applied

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts