Question: 59 WBS ELEMENT DESCRIPTION CASE STUDY 2.3 The WBS Dictionary is being prepared to define the scope of work to be included within the WBS

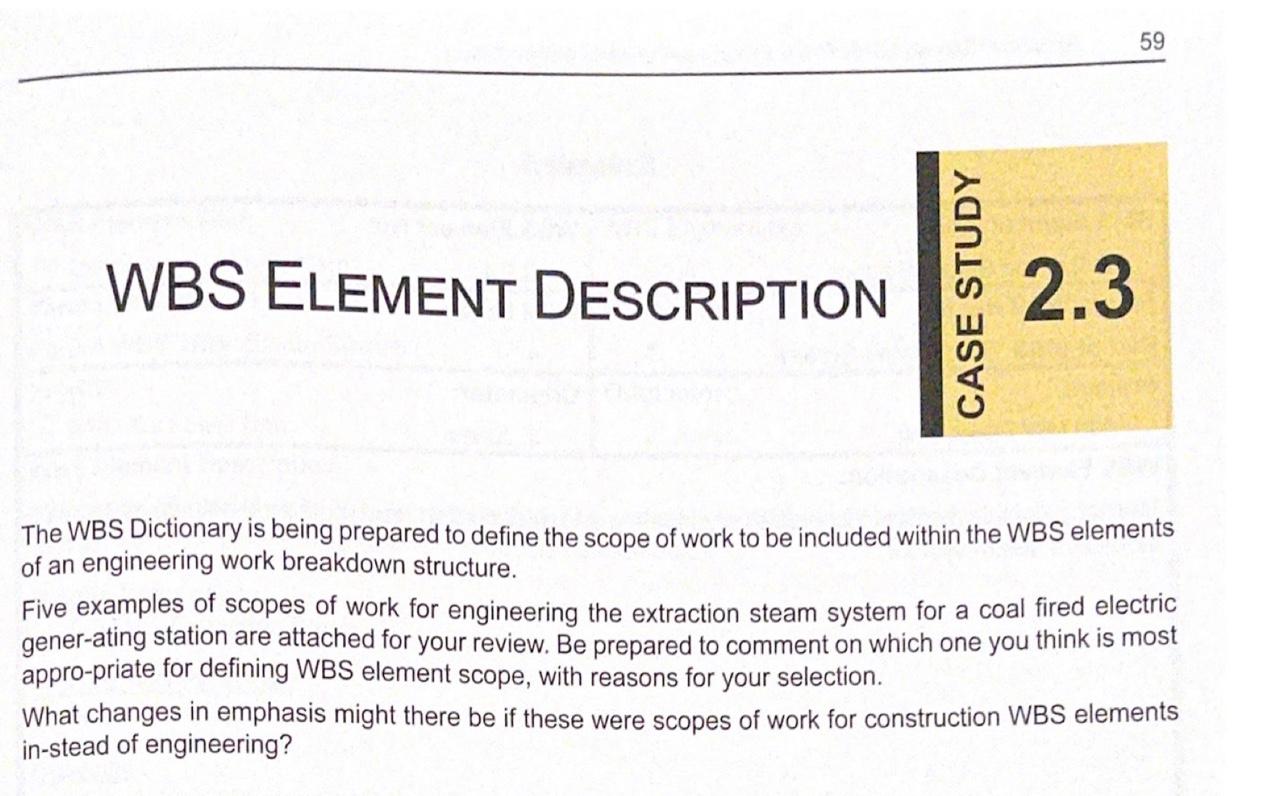

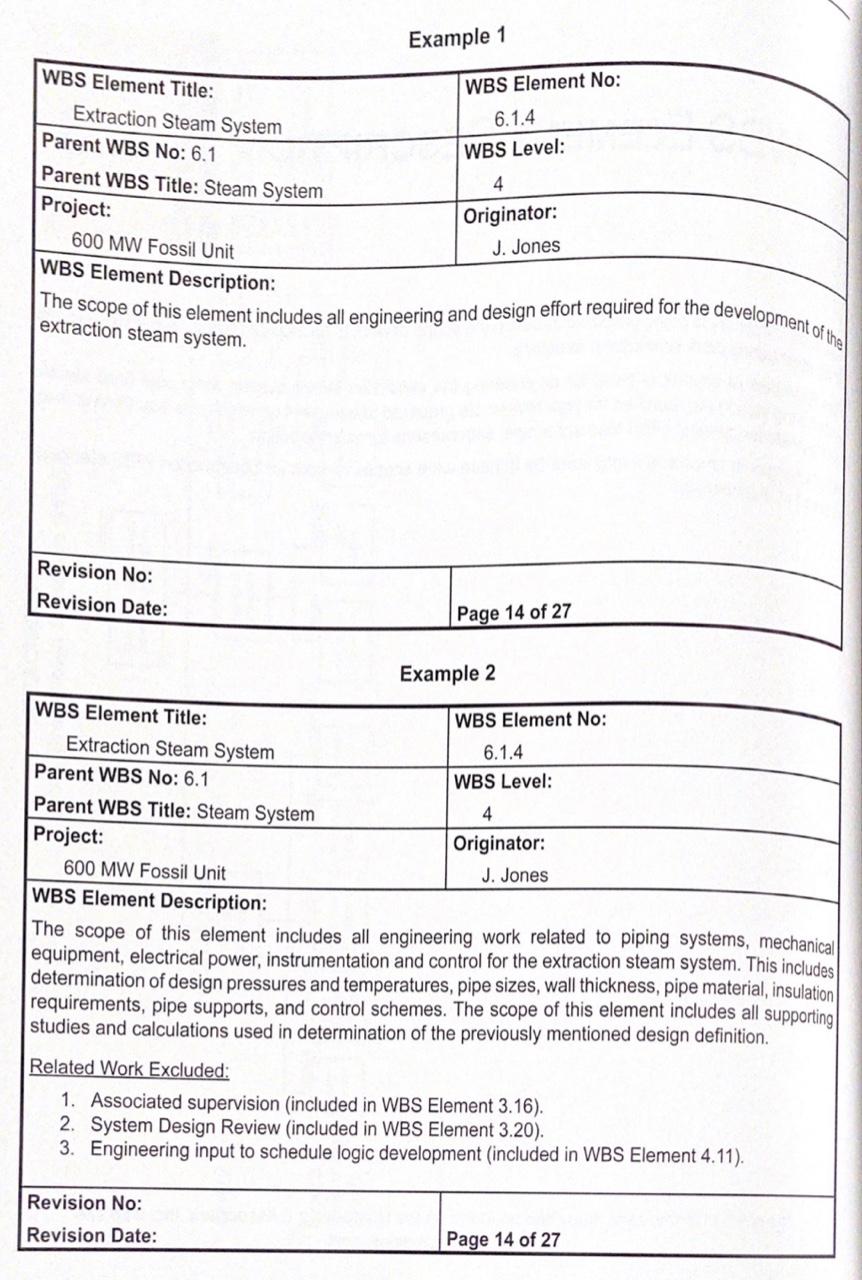

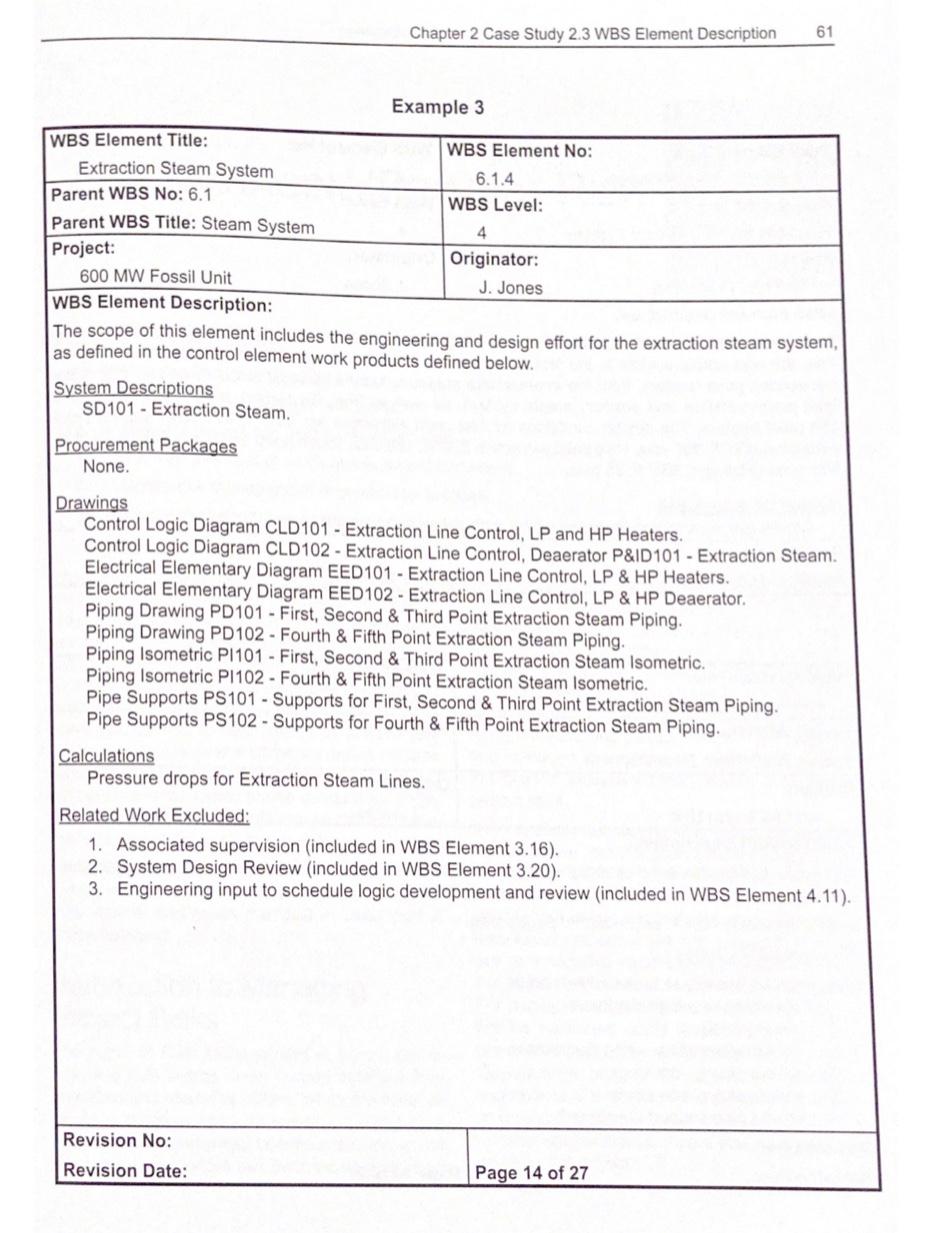

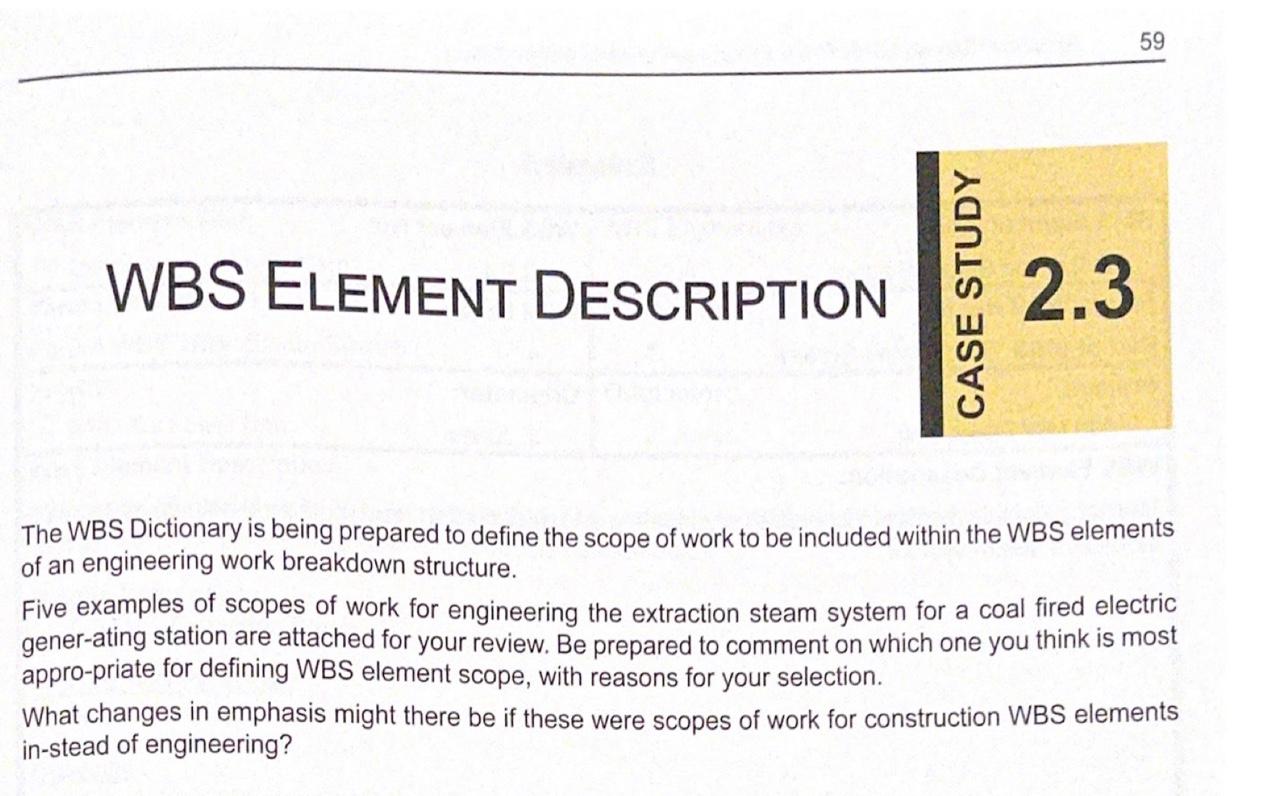

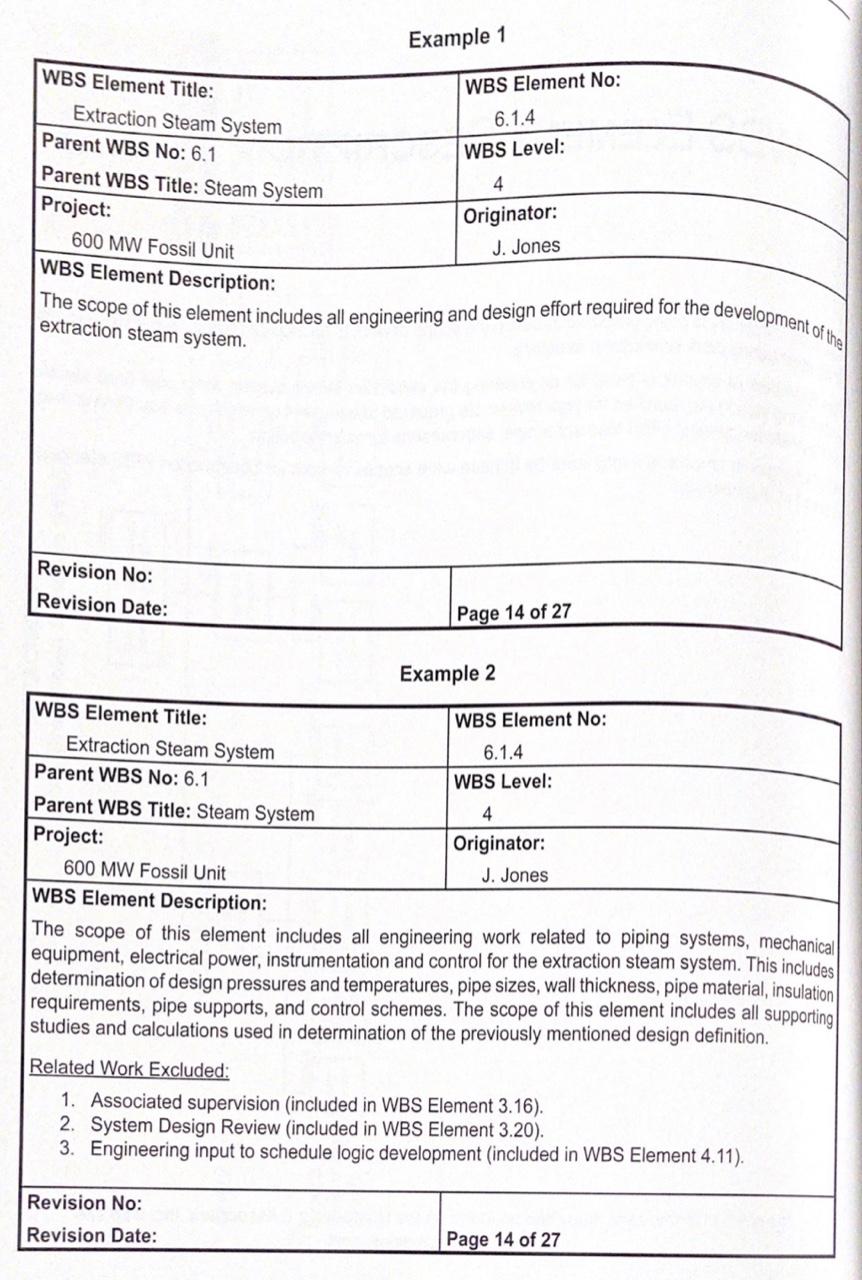

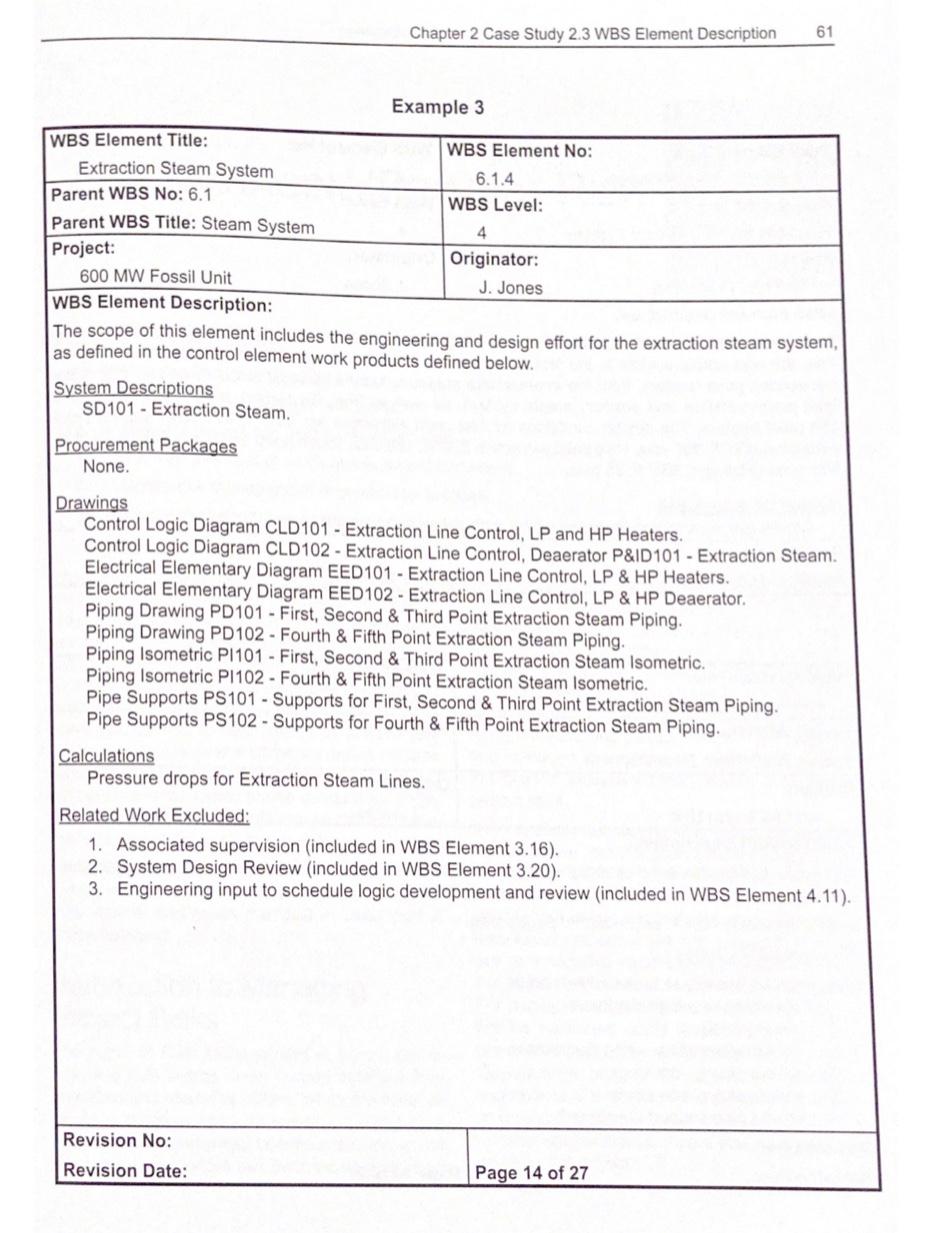

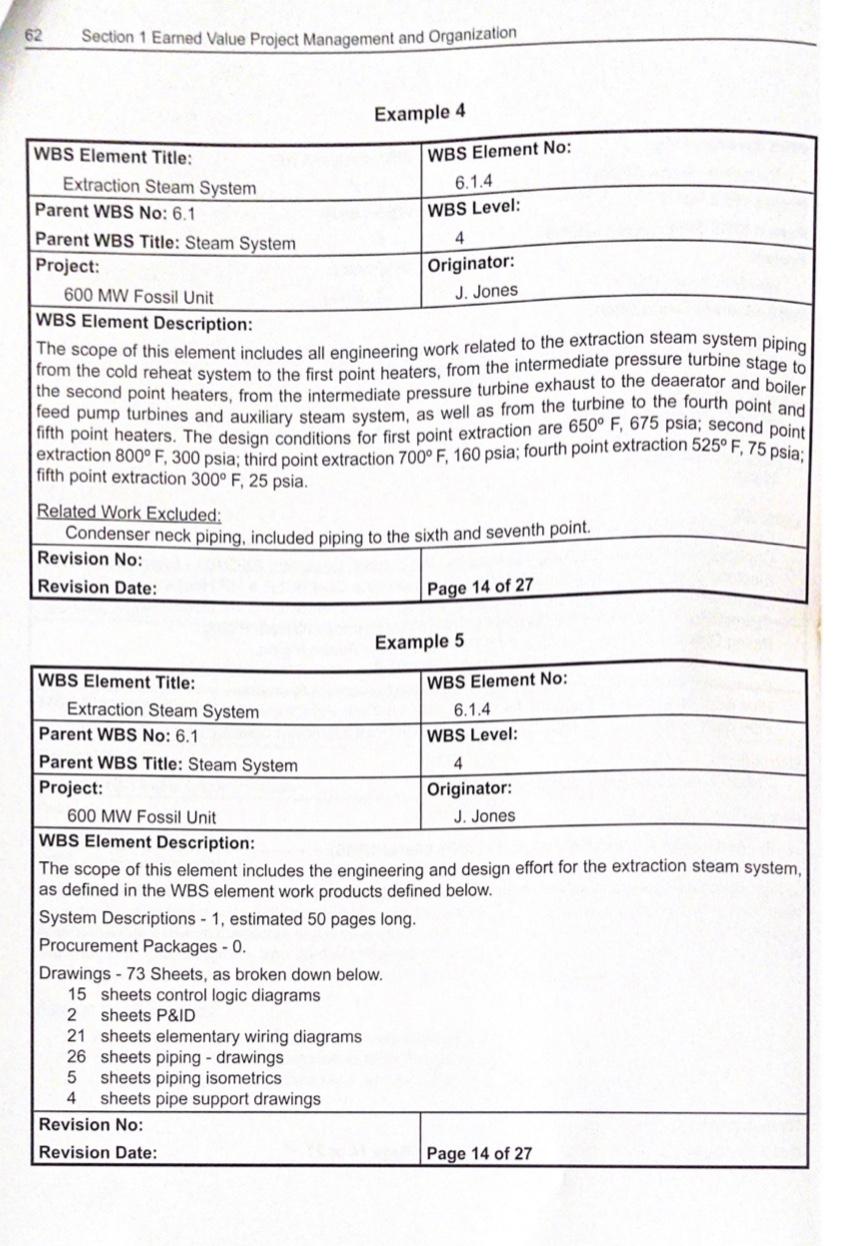

59 WBS ELEMENT DESCRIPTION CASE STUDY 2.3 The WBS Dictionary is being prepared to define the scope of work to be included within the WBS elements of an engineering work breakdown structure. Five examples of scopes of work for engineering the extraction steam system for a coal fired electric gener-ating station are attached for your review. Be prepared to comment on which one you think is most appro-priate for defining WBS element scope, with reasons for your selection. What changes in emphasis might there be if these were scopes of work for construction WBS elements in-stead of engineering? Example 1 WBS Element No: 6.1.4 WBS Level: WBS Element Title: Extraction Steam System Parent WBS No: 6.1 Parent WBS Title: Steam System Project: 600 MW Fossil Unit WBS Element Description: 4 Originator: J. Jones The scope of this element includes all engineering and design effort required for the development of the extraction steam system. Revision No: Revision Date: Page 14 of 27 Example 2 WBS Element Title: Extraction Steam System WBS Element No: 6.1.4 Parent WBS No: 6.1 WBS Level: 4 Jone Parent WBS Title: Steam System Project: Originator: 600 MW Fossil Unit WBS Element Description: The scope of this element includes all engineering work related to piping systems, mechanical equipment, electrical power, instrumentation and control for the extraction steam system. This includes determination of design pressures and temperatures, pipe sizes, wall thickness, pipe material, insulation requirements, pipe supports, and control schemes. The scope of this element includes all supporting studies and calculations used in determination of the previously mentioned design definition. Related Work Excluded: 1. Associated supervision (included in WBS Element 3.16). 2. System Design Review (included in WBS Element 3.20). 3. Engineering input to schedule logic development (included in WBS Element 4.11). Revision No: Revision Date: Page 14 of 27 Chapter 2 Case Study 2.3 WBS Element Description 61 Example 3 WBS Element Title: WBS Element No: Extraction Steam System 6.1.4 Parent WBS No: 6.1 WBS Level: Parent WBS Title: Steam System 4 Project: Originator: 600 MW Fossil Unit J. Jones WBS Element Description: The scope of this element includes the engineering and design effort for the extraction steam system, as defined in the control element work products defined below. System Descriptions SD 101 - Extraction Steam. Procurement Packages None. Drawings Control Logic Diagram CLD101 - Extraction Line Control, LP and HP Heaters. Control Logic Diagram CLD102 - Extraction Line Control, Deaerator P&ID 101 - Extraction Steam Electrical Elementary Diagram EED101 - Extraction Line Control, LP & HP Heaters. Electrical Elementary Diagram EED 102 - Extraction Line Control, LP & HP Deaerator. Piping Drawing PD101 - First, Second & Third Point Extraction Steam Piping. Piping Drawing PD102 - Fourth & Fifth Point Extraction Steam Piping. Piping Isometric PI101 - First, Second & Third Point Extraction Steam Isometric, Piping Isometric PI 102 - Fourth & Fifth Point Extraction Steam Isometric. Pipe Supports PS 101 - Supports for First, Second & Third Point Extraction Steam Piping. Pipe Supports PS102 - Supports for Fourth & Fifth Point Extraction Steam Piping. Calculations Pressure drops for Extraction Steam Lines. Related Work Excluded: 1. Associated supervision (included in WBS Element 3.16). 2. System Design Review (included in WBS Element 3.20). 3. Engineering input to schedule logic development and review (included in WBS Element 4.11). Revision No: Revision Date: Page 14 of 27 62 Section 1 Earned Value Project Management and Organization Example 4 WBS Element No: 6.1.4 WBS Level: WBS Element Title: Extraction Steam System Parent WBS No: 6.1 Parent WBS Title: Steam System Project: 600 MW Fossil Unit WBS Element Description: 4 Originator: J. Jones from the cold reheat system to the first point heaters, from the intermediate pressure turbine stage to from scope of this element includes all engineering work related to the extraction steam system piping the second point heaters, from the intermediate pressure turbine exhaust to the deaerator and boiler feed pump turbines and auxiliary steam system, as well as from the turbine to the fourth point and fifth point heaters. The design conditions for first point extraction are 650F, 675 psia; second point extraction 800F, 300 psia; third point extraction 700F, 160 psia; fourth point extraction 525 F, 75 psia: fifth point extraction 300 F, 25 psia. Related Work Excluded: Condenser neck piping, included piping to the sixth and seventh point. Revision No: Revision Date: Page 14 of 27 Example 5 WBS Element No: WBS Element Title: Extraction Steam System Parent WBS No: 6.1 6.1.4 WBS Level: Parent WBS Title: Steam System 4 Project: Originator: 600 MW Fossil Unit J. Jones WBS Element Description: The scope of this element includes the engineering and design effort for the extraction steam system, as defined in the WBS element work products defined below. System Descriptions - 1. estimated 50 pages long. Procurement Packages - 0. Drawings - 73 Sheets, as broken down below. 15 sheets control logic diagrams 2 sheets P&ID 21 sheets elementary wiring diagrams 26 sheets piping - drawings 5 sheets piping isometrics 4 sheets pipe support drawings Revision No: Revision Date: Page 14 of 27