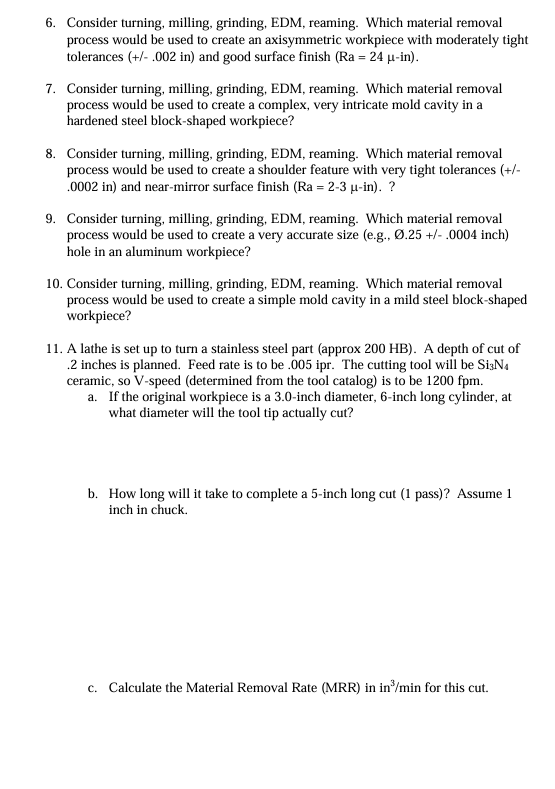

Question: 6 . Consider turning, milling, grinding, EDM, reaming. Which material removal process would be used to create an axisymmetric workpiece with moderately tight tolerances (

Consider turning, milling, grinding, EDM, reaming. Which material removal process would be used to create an axisymmetric workpiece with moderately tight tolerances mathrmin and good surface finish mathrmRamu in

Consider turning, milling, grinding, EDM, reaming. Which material removal process would be used to create a complex, very intricate mold cavity in a hardened steel blockshaped workpiece?

Consider turning, milling, grinding, EDM, reaming. Which material removal process would be used to create a shoulder feature with very tight tolerances in and nearmirror surface finish mathrmRamu in

Consider turning, milling, grinding, EDM, reaming. Which material removal process would be used to create a very accurate size eg inch hole in an aluminum workpiece?

Consider turning, milling, grinding, EDM, reaming. Which material removal process would be used to create a simple mold cavity in a mild steel blockshaped workpiece?

A lathe is set up to turn a stainless steel part approx HB A depth of cut of inches is planned. Feed rate is to be ipr The cutting tool will be mathrmSimathrm~N ceramic, so Vspeed determined from the tool catalog is to be fpm

a If the original workpiece is a inch diameter, inch long cylinder, at what diameter will the tool tip actually cut?

b How long will it take to complete a inch long cut pass Assume inch in chuck.

c Calculate the Material Removal Rate MRR in mathrminmathrmmin for this cut.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock