Question: 63) A machine is available 10 hours a day setup. 10% of the parts made are defective and must during which both setup and fabricati

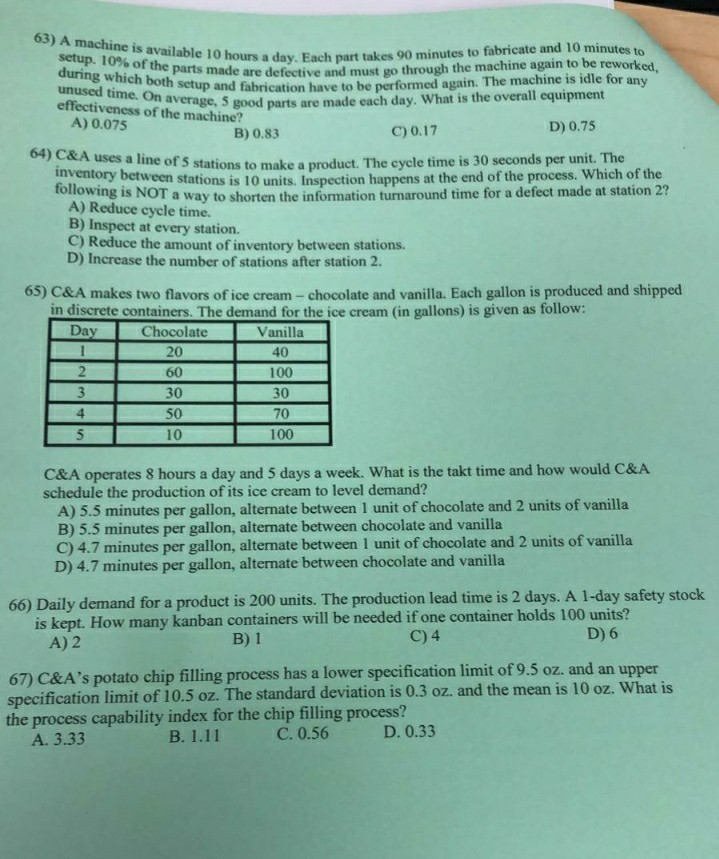

63) A machine is available 10 hours a day setup. 10% of the parts made are defective and must during which both setup and fabricati unused time. On average, 5 good par effectiveness of the machine? A) 0.075 ole 10 hours a day. Each part takes 90 minutes to fabricate and 10 minutes to * made are defective and must go through the machine again to be reworked setup and fabrication have to be performed again. The machine is idle for any verage, 5 good parts are made each day. What is the overall equipment B) 0.83 C) 0.17 D) 0.75 64) C&A uses a line of 5 stations to make a pro sa line of 5 stations to make a product. The cycle time is 30 seconds per unit. The inventory between stations is 10 units. In between stations is 10 units. Inspection happens at the end of the process. Which of the owing is NOT a way to shorten the information turnaround time for a defect made at station 2? A) Reduce cycle time. B) Inspect at every station. C) Reduce the amount of inventory between stations. D) Increase the number of stations after station 2. Os) C&A makes two flavors of ice cream - chocolate and vanilla. Each gallon is produced and shipped in discrete containers. The demand for the ice cream (in gallons) is given as follow: Day Chocolate Vanilla LT 20 40 60 100 30 30 4 50 70 5 10 100 2 C&A operates 8 hours a day and 5 days a week. What is the takt time and how would C&A schedule the production of its ice cream to level demand? A) 5.5 minutes per gallon, alternate between 1 unit of chocolate and 2 units of vanilla B) 5.5 minutes per gallon, alternate between chocolate and vanilla C) 4.7 minutes per gallon, alternate between 1 unit of chocolate and 2 units of vanilla D) 4.7 minutes per gallon, alternate between chocolate and vanilla 66) Daily demand for a product is 200 units. The production lead time is 2 days. A 1-day safety stock is kept. How many kanban containers will be needed if one container holds 100 units? C) 4 D) 6 A) 2 B) 1 67) C&A's potato chip filling process has a lower specification limit of 9.5 oz. and an upper specification limit of 10.5 Oz. The standard deviation is 0.3 oz. and the mean is 10 oz. What is the process capability index for the chip filling process? A. 3.33 B. 1.11 C. 0.56 D. 0.33

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock