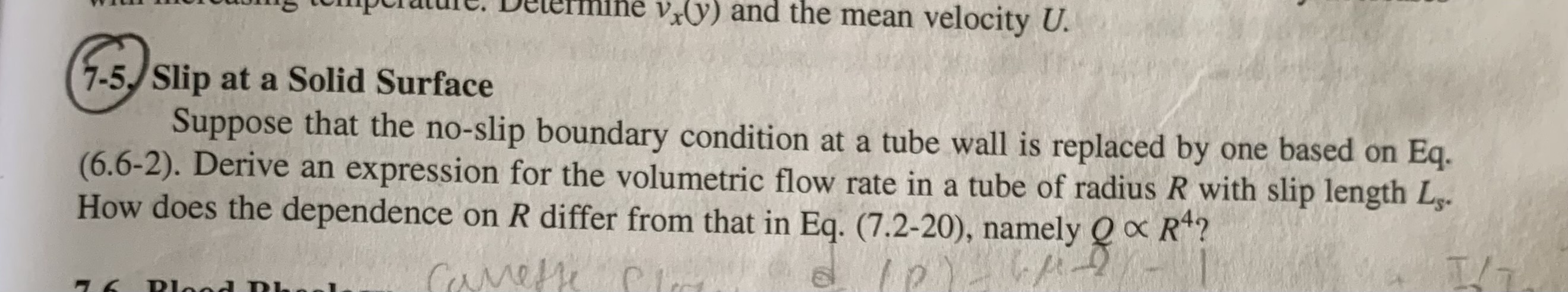

Question: 7-5. Slip at a Solid Surface Suppose that the no-slip boundary condition at a tube wall is replaced by one based on Eq. (6.6-2). Derive

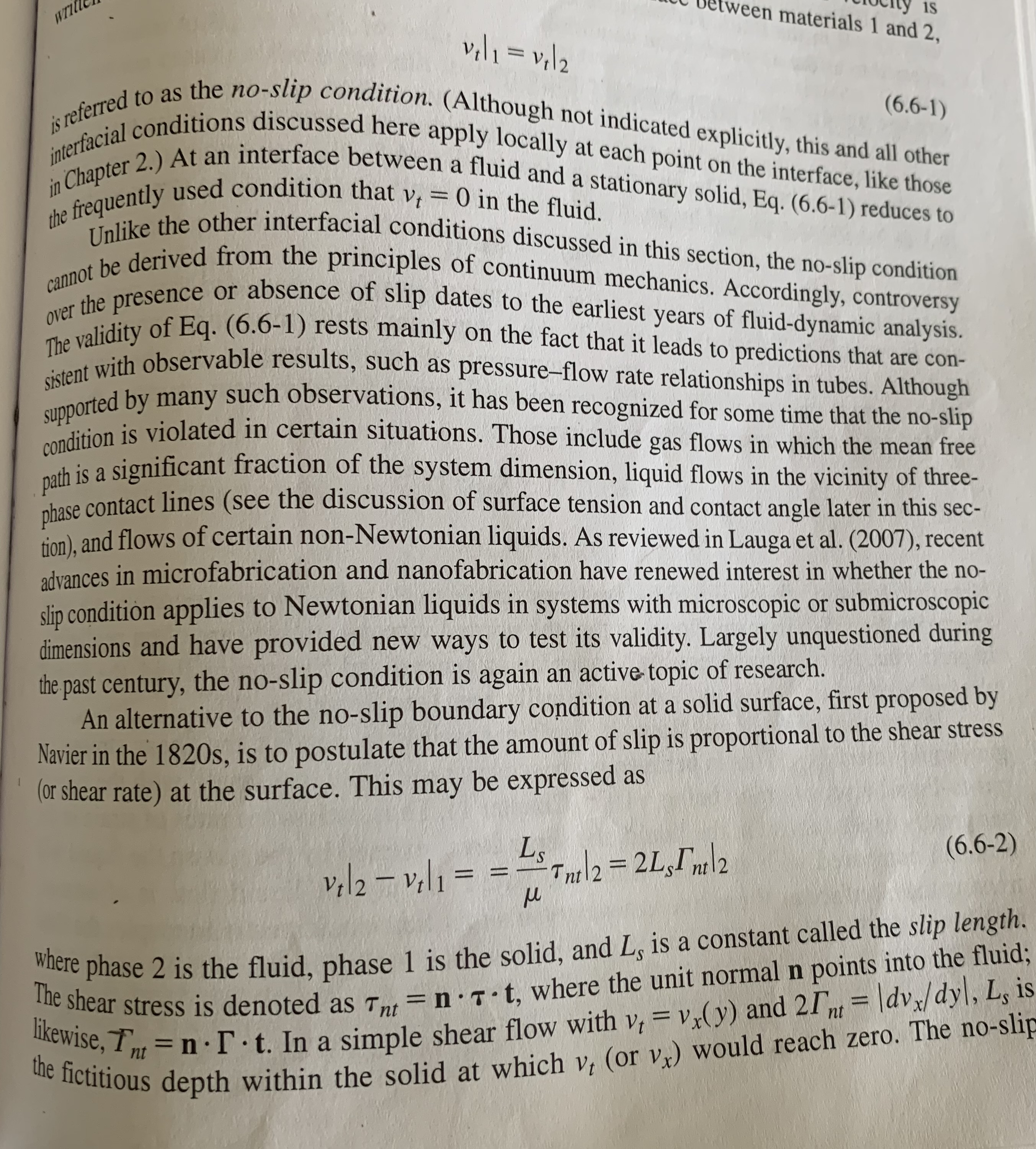

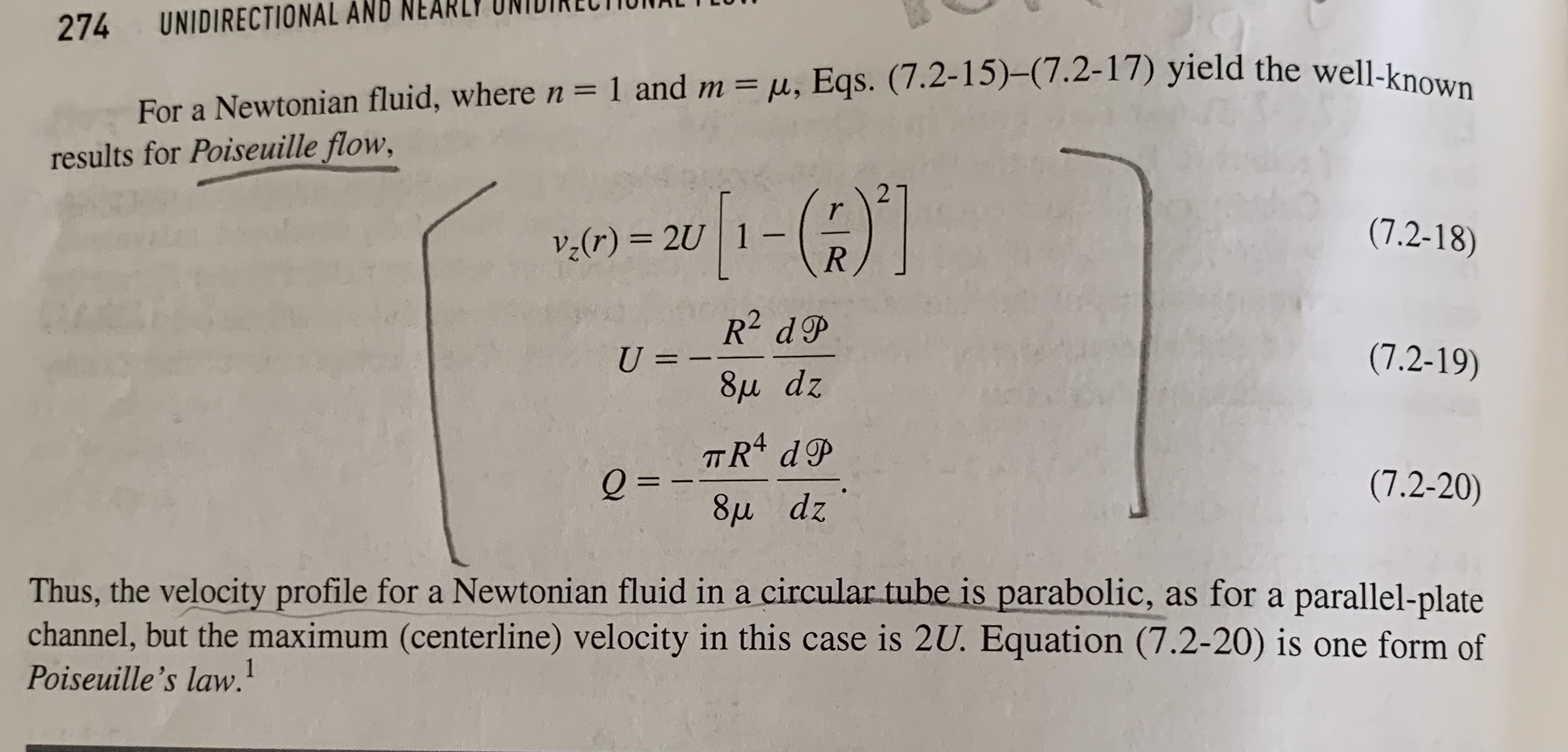

7-5. Slip at a Solid Surface Suppose that the no-slip boundary condition at a tube wall is replaced by one based on Eq. (6.6-2). Derive an expression for the volumetric flow rate in a tube of radius R with slip length Ls. How does the dependence on R differ from that in Eq. (7.2-20), namely QR4 ? vt1=vt2 is referred to as the no-slip condition. (Although not indicated explicitly, this and all other in in Chapter 2.) At an interface between a fluid and at each point on the interface, like those the frequently used condition that vt=0 in the fluid. Unlike the other interfacial conditions discussed in this section, the no-slip condition cannot be derived from the principles of continuum mechanics. Accordingly, controversy over the presence or absence of slip dates to the earliest years of fluid-dynamic analysis. The validity of Eq. (6.6-1) rests mainly on the fact that it leads to predictions that are consistent with observable results, such as pressure-flow rate relationships in tubes. Although supported by many such observations, it has been recognized for some time that the no-slip condition is violated in certain situations. Those include gas flows in which the mean free path is a significant fraction of the system dimension, liquid flows in the vicinity of threephase contact lines (see the discussion of surface tension and contact angle later in this section), and flows of certain non-Newtonian liquids. As reviewed in Lauga et al. (2007), recent advances in microfabrication and nanofabrication have renewed interest in whether the noslip condition applies to Newtonian liquids in systems with microscopic or submicroscopic dimensions and have provided new ways to test its validity. Largely unquestioned during the past century, the no-slip condition is again an active topic of research. An alternative to the no-slip boundary condition at a solid surface, first proposed by Navier in the 1820s, is to postulate that the amount of slip is proportional to the shear stress (or shear rate) at the surface. This may be expressed as vt2vt1==Lsnt2=2Lsnt2 where phase 2 is the fluid, phase 1 is the solid, and Ls is a constant called the slip length The shear stress is denoted as nt=nt, where the unit normal n points into the fluid likewise, Tnt=nt. In a simple shear flow with vt=vx(y) and 2nt=dvx/dy,Ls i the fictitious depth within the solid at which vt (or vx ) would reach zero. The no-sli For a Newtonian fluid, where n=1 and m=, Eqs. (7.2-15)-(7.2-17) yield the well-known results for Poiseuille flow, vz(r)=2U[1(Rr)2]U=8R2dzdPQ=8R4dzdP Thus, the velocity profile for a Newtonian fluid in a circular tube is parabolic, as for a parallel-plate channel, but the maximum (centerline) velocity in this case is 2U. Equation (7.2-20) is one form of Poiseuille's law. 1

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts