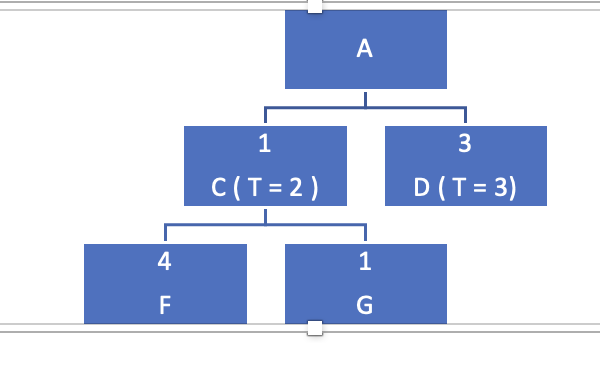

Question: 8 . 1 4 Consider product A , shown in the figure below. All lead times are one week unless stated otherwise. In the figure,

Consider product A shown in the figure below. All lead times are one week unless stated otherwise. In the figure, numerical values indicate the number of child items needed to make on parent item. The master production schedule for planned assemblies over the next ten weeks for product A is as follows: and Current onhand inventory levels are part Ds part Fs and parts of type G In addition, an order of part Cs is in process and should be completed in time for use in period A batch of parts type Ds is in the shop and due at the start of week Plan order release for all items using lotforlot scheduling. Assume lead time times can be kept. Determine Planned order releases.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock