Question: A 103/4 inch surface casing is to be set at 4500ft with 10.6ppg mud in the hole. Design the casing to achieve minimum cost. Only

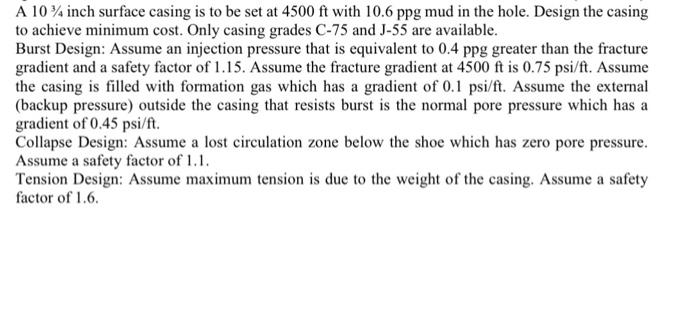

A 103/4 inch surface casing is to be set at 4500ft with 10.6ppg mud in the hole. Design the casing to achieve minimum cost. Only casing grades C75 and J55 are available. Burst Design: Assume an injection pressure that is equivalent to 0.4ppg greater than the fracture gradient and a safety factor of 1.15 . Assume the fracture gradient at 4500ft is 0.75psi/ft. Assume the casing is filled with formation gas which has a gradient of 0.1psi/ft. Assume the external (backup pressure) outside the casing that resists burst is the normal pore pressure which has a gradient of 0.45psi/ft. Collapse Design: Assume a lost circulation zone below the shoe which has zero pore pressure. Assume a safety factor of 1.1 . Tension Design: Assume maximum tension is due to the weight of the casing. Assume a safety factor of 1.6

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts