Question: (a) Assuming one-week lead time for each operation, make a detailed capacity check to determine the the planned order releases and scheduled receipts are feasible.

(a) Assuming one-week lead time for each operation, make a detailed capacity check to determine the the planned order releases and scheduled receipts are feasible. If not, revise the planned order releases and/or scheduled receipts.

(b) Using the Microsoft Excel, draw the load profiles of the work centers in all weeks where a production takes place.

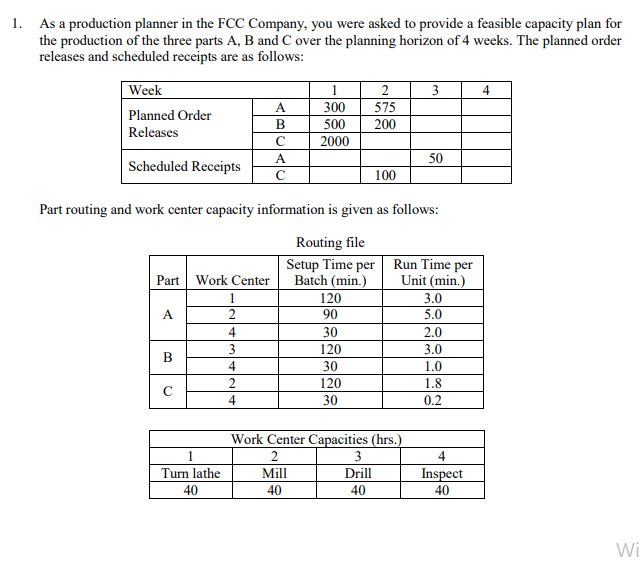

1. As a production planner in the FCC Company, you were asked to provide a feasible capacity plan for the production of the three parts A, B and Cover the planning horizon of 4 weeks. The planned order releases and scheduled receipts are as follows: 3 4 Week Planned Order Releases 1 300 500 2000 2 575 200 A B C A 50 Scheduled Receipts 100 Part routing and work center capacity information is given as follows: Routing file Setup Time per Run Time per Part Work Center Batch (min.) Unit (min.) 1 120 3.0 A 2 90 5.0 4 30 2.0 3 120 3.0 B 4 30 2 120 1.8 4 30 0.2 B 1.0 1 Turn lathe 40 Work Center Capacities (hrs.) 3 Mill Drill 40 40 Inspect 40 Wi 1. As a production planner in the FCC Company, you were asked to provide a feasible capacity plan for the production of the three parts A, B and Cover the planning horizon of 4 weeks. The planned order releases and scheduled receipts are as follows: 3 4 Week Planned Order Releases 1 300 500 2000 2 575 200 A B C A 50 Scheduled Receipts 100 Part routing and work center capacity information is given as follows: Routing file Setup Time per Run Time per Part Work Center Batch (min.) Unit (min.) 1 120 3.0 A 2 90 5.0 4 30 2.0 3 120 3.0 B 4 30 2 120 1.8 4 30 0.2 B 1.0 1 Turn lathe 40 Work Center Capacities (hrs.) 3 Mill Drill 40 40 Inspect 40 WiStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts