Question: a. b. c. note: chegg policy has changed so please answer all questions. if all questions are not answered i will downvote and report Williams

a.

b. c.

c.

note: chegg policy has changed so please answer all questions. if all questions are not answered i will downvote and report

note: chegg policy has changed so please answer all questions. if all questions are not answered i will downvote and report

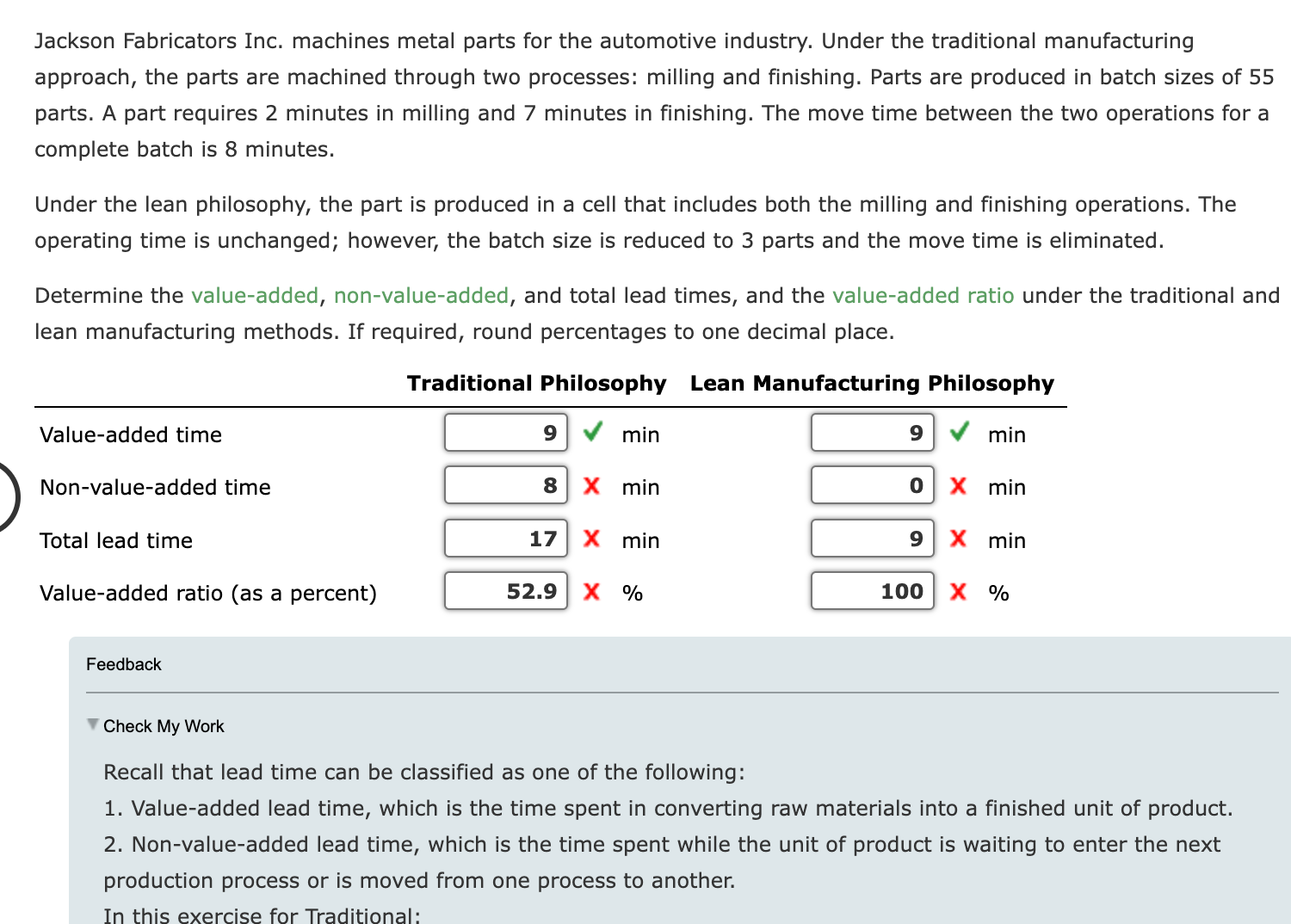

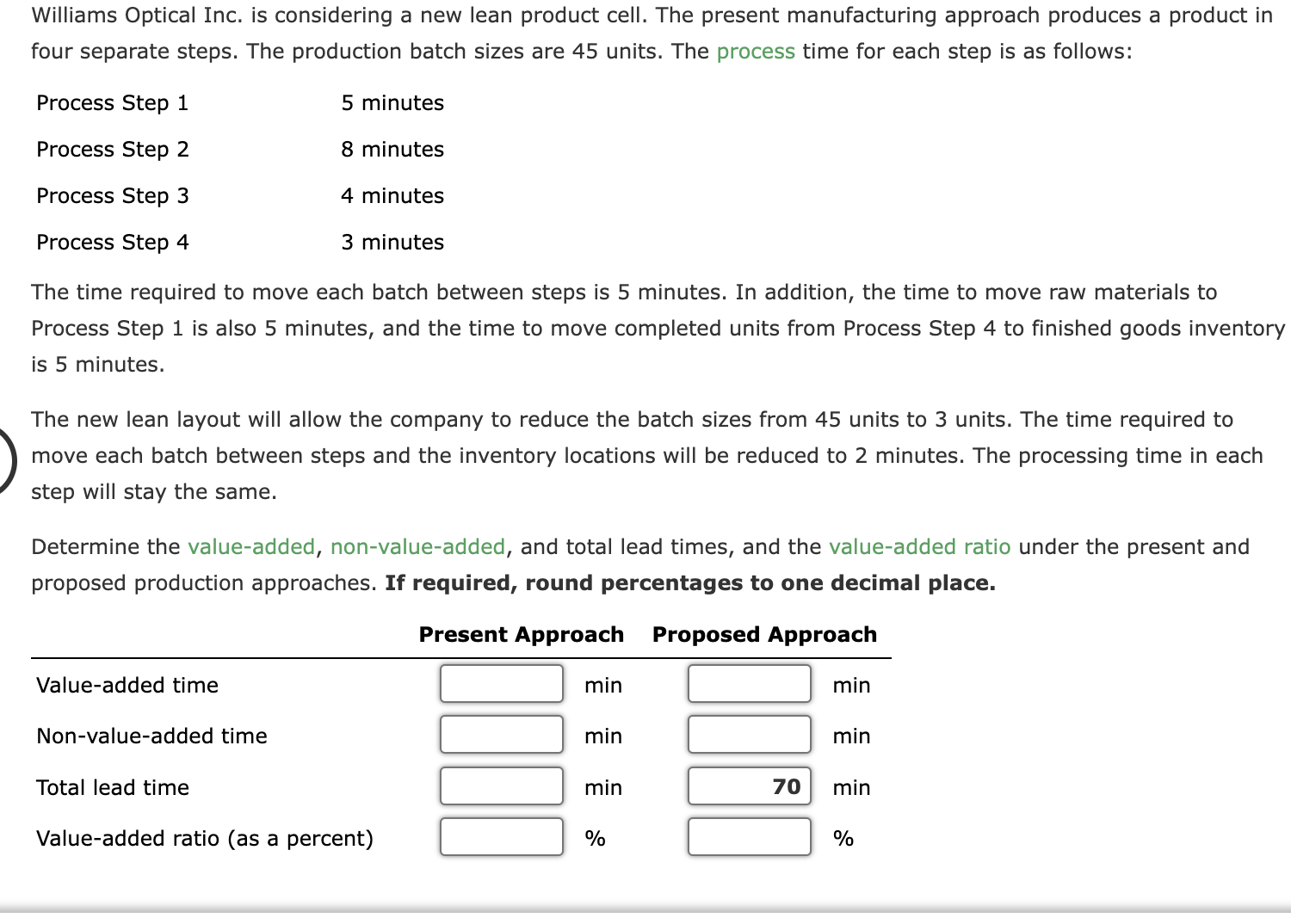

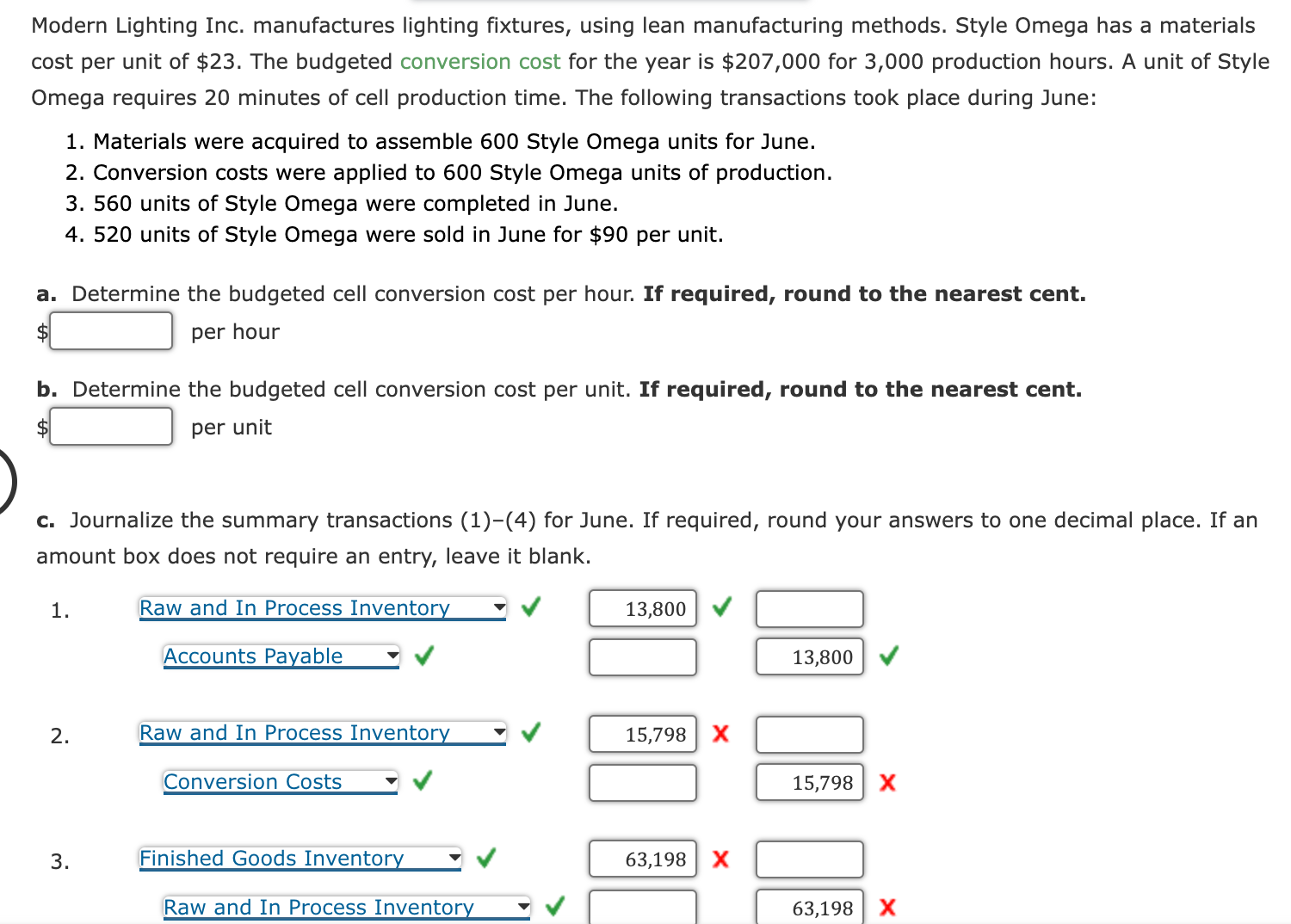

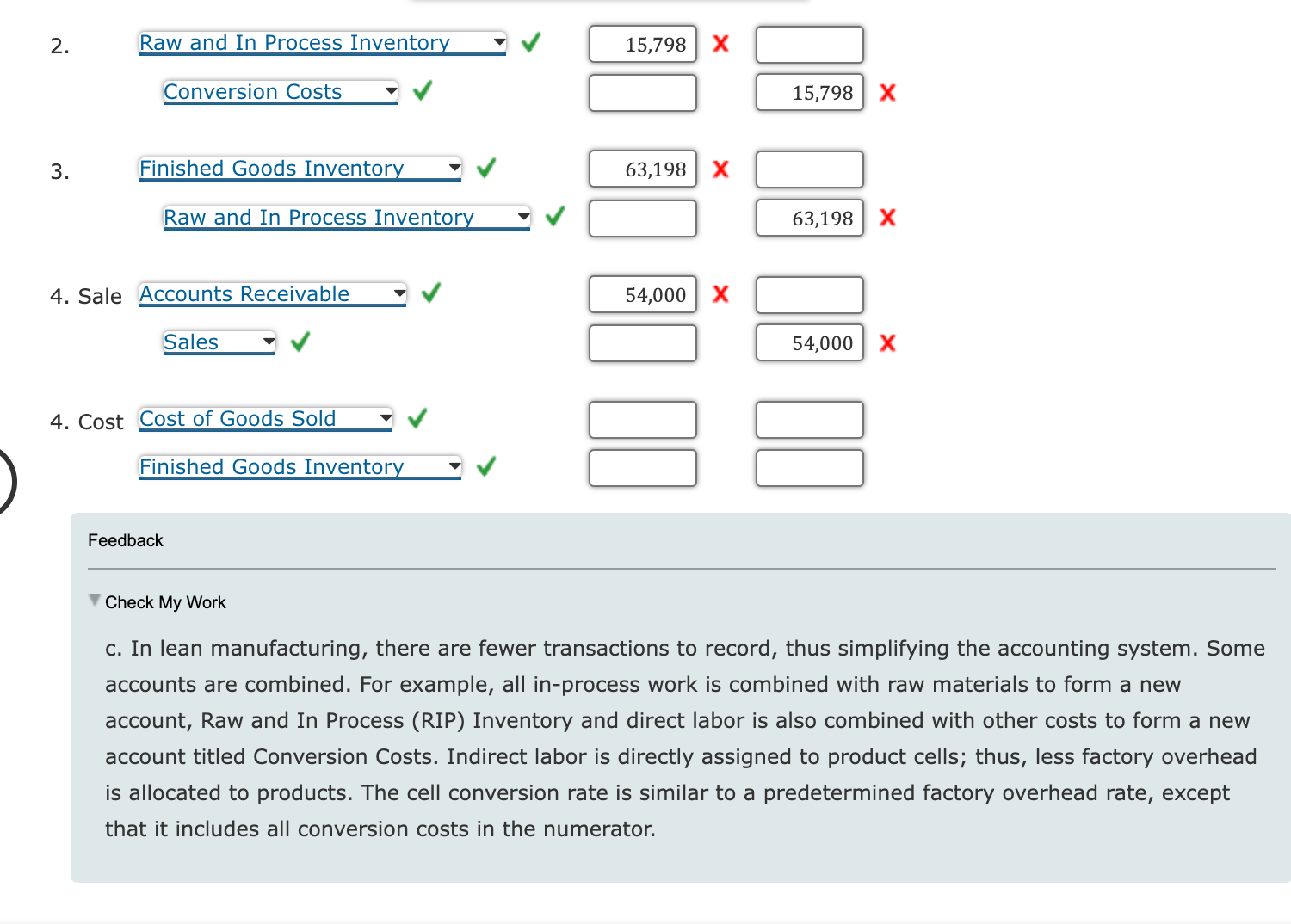

Williams Optical Inc. is considering a new lean product cell. The present manufacturing approach produces a product in four separate steps. The production batch sizes are 45 units. The process time for each step is as follows: The time required to move each batch between steps is 5 minutes. In addition, the time to move raw materials to Process Step 1 is also 5 minutes, and the time to move completed units from Process Step 4 to finished goods inventory is 5 minutes. The new lean layout will allow the company to reduce the batch sizes from 45 units to 3 units. The time required to move each batch between steps and the inventory locations will be reduced to 2 minutes. The processing time in each step will stay the same. Determine the value-added, non-value-added, and total lead times, and the value-added ratio under the present and proposed production approaches. If required, round percentages to one decimal place. Modern Lighting Inc. manufactures lighting fixtures, using lean manufacturing methods. Style Omega has a materials cost per unit of $23. The budgeted conversion cost for the year is $207,000 for 3,000 production hours. A unit of Style Omega requires 20 minutes of cell production time. The following transactions took place during June: 1. Materials were acquired to assemble 600 Style Omega units for June. 2. Conversion costs were applied to 600 Style Omega units of production. 3. 560 units of Style Omega were completed in June. 4. 520 units of Style Omega were sold in June for $90 per unit. a. Determine the budgeted cell conversion cost per hour. If required, round to the nearest cent. q per hour b. Determine the budgeted cell conversion cost per unit. If required, round to the nearest cent. $ per unit c. Journalize the summary transactions (1)-(4) for June. If required, round your answers to one decimal place. If an amount box does not require an entry, leave it blank. Jackson Fabricators Inc. machines metal parts for the automotive industry. Under the traditional manufacturing approach, the parts are machined through two processes: milling and finishing. Parts are produced in batch sizes of 55 parts. A part requires 2 minutes in milling and 7 minutes in finishing. The move time between the two operations for a complete batch is 8 minutes. Under the lean philosophy, the part is produced in a cell that includes both the milling and finishing operations. The operating time is unchanged; however, the batch size is reduced to 3 parts and the move time is eliminated. Determine the value-added, non-value-added, and total lead times, and the value-added ratio under the traditional and lean manufacturing methods. If required, round percentages to one decimal place. Feedback Check My Work Recall that lead time can be classified as one of the following: 1. Value-added lead time, which is the time spent in converting raw materials into a finished unit of product. 2. Non-value-added lead time, which is the time spent while the unit of product is waiting to enter the next production process or is moved from one process to another. Check My Work c. In lean manufacturing, there are fewer transactions to record, thus simplifying the accounting system. Some accounts are combined. For example, all in-process work is combined with raw materials to form a new account, Raw and In Process (RIP) Inventory and direct labor is also combined with other costs to form a new account titled Conversion Costs. Indirect labor is directly assigned to product cells; thus, less factory overhead is allocated to products. The cell conversion rate is similar to a predetermined factory overhead rate, except that it includes all conversion costs in the numerator

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts