Question: A cement importer operates two plants where they repackage bulk imported cement into smaller bags for end customers. The suppliers are willing to supply

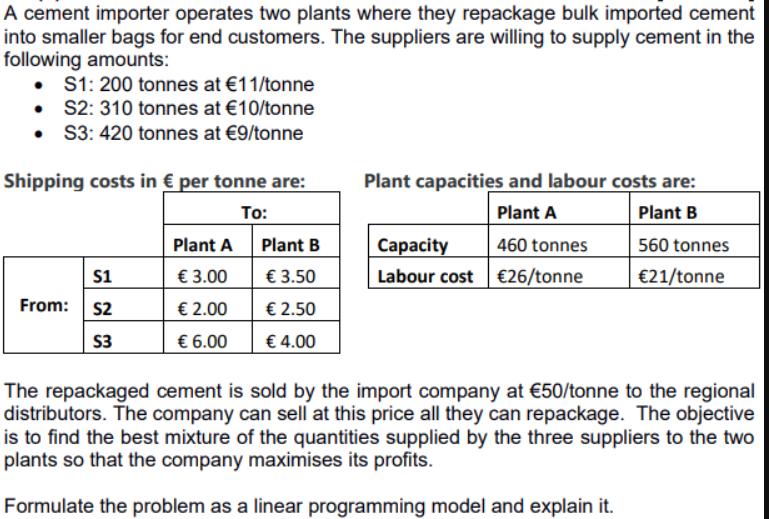

A cement importer operates two plants where they repackage bulk imported cement into smaller bags for end customers. The suppliers are willing to supply cement in the following amounts: S1: 200 tonnes at 11/tonne S2: 310 tonnes at 10/tonne S3: 420 tonnes at 9/tonne Shipping costs in per tonne are: To: S1 From: S2 S3 Plant A Plant B 3.00 3.50 2.00 2.50 6.00 4.00 Plant capacities and labour costs are: Plant A Plant B 460 tonnes 560 tonnes 21/tonne Capacity Labour cost 26/tonne The repackaged cement is sold by the import company at 50/tonne to the regional distributors. The company can sell at this price all they can repackage. The objective is to find the best mixture of the quantities supplied by the three suppliers to the two plants so that the company maximises its profits. Formulate the problem as a linear programming model and explain it.

Step by Step Solution

3.41 Rating (154 Votes )

There are 3 Steps involved in it

Linear Programming Formulation for Cement Importer The goal is to maximize the profit of the cement importer by determining the optimal quantities of ... View full answer

Get step-by-step solutions from verified subject matter experts