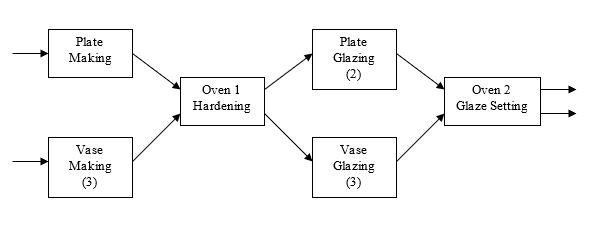

Question: A ceramics company makes plates and vases. The basic shapes created at separate workstations1 for plates and 1 for vases. Both types are made one

A ceramics company makes plates and vases. The basic shapes created at separate workstations1 for plates and 1 for vases. Both types are made one at a time by hand. It takes a worker an average of 12 min to A ceramics company makes plates and vases. The basic shapes are made out of clay at separate workstations1 for plates and 1 for vases form a plate, and it takes a worker an average of 20 min to form a vase. There is 1 worker at the plate forming station and 3 workers at the vase forming station. After being formed, the raw ceramics pieces all go to a single oven where they are baked until hard. The oven can accommodate either of the ceramics types, but plates and vases are always baked in separate batches. The oven can hold 230 vases at a time or 460 plates at a time. It takes 24 hours (including loading and unloading) to bake the clay to its proper hardness (regardless of ceramics type).

After baking the vases move to a vase glazing station where workers use glaze to hand-paint designs on the pieces. Each worker does 1 piece at a time, and it takes an average of 30 min per piece. There are 3 workers at this workstation. After baking, all of the plates move to a separate plate glazing station where they receive a simple coat of a single-color glaze. Each worker does 1 piece at a time, and it takes an average of 20 min per piece. There are 2 workers at this workstation.

After glazing, all pieces (plates and vases) go to a single oven (different from the previous oven) where they are baked to set the glaze. This oven can hold 300 plates or 200 vases at a time, and plates and vases are always baked in separate batches. It takes 24 hours (including loading and unloading) to bake pieces until the glaze is set (regardless of ceramics type).

The following is the process flow diagram for this system.

- Assuming that the process runs 24 hours per day, and that in the long run half of the pieces Artistic Ceramics makes are plates and half are vases, calculate the long-run average processing rate (in pieces per hour) for each workstation in isolation. Make plates processing rate _________________ (pieces/hr) Make vases processing rate _________________ (pieces/hr) Oven 1 (clay hardening) processing rate _________________ (pieces/hr) Plate glazing processing rate _________________ (pieces/hr) Vase glazing processing rate _________________ (pieces/hr) Oven 2 (glaze setting) processing rate _________________ (pieces/hr)

- Current market demand is for 100 plates per day and 100 vases per day. Does the company have sufficient capacity to meet demand? Briefly justify your answer. Answer: Yes No (Bold and underline one) Justify: ___________________________________________________________ _________________________________________________________________

- Suppose that Artistic Ceramics learns that its second oven is near the end of its life. The company is not sure that it wants to invest the money to purchase a new oven, so it is considering using the first oven to bake the original pieces and also to set the glaze. Baking and glaze setting for plates and vases would all be d1in separate batches (i.e., four different types of batches). Plate batches (for either baking or glaze setting) would contain 460 plates, while vase batches (for either baking or glaze setting) would contain 230 vases. If Artistic Ceramics decides to do this, what is the maximum number of plates and vases that they could produce per day assuming that they still want to produce equal numbers of each? Plate processing rate _________________ (pieces/day) Vase processing rate _________________ (pieces/day)

- (For this question, assume the original problem setting i.e., assume that both ovens are still available.) DIY Ceramics is a chain of stores that provide customers with unglazed ceramics that customers then decorate with glaze in the DIY Ceramics store. They have approached Artistic Ceramics with an offer to purchase 100 unglazed vases per day from the company. (Producing these vases does not require Artistic Ceramics to do the glazing or the final baking that sets the glaze.) Does Artistic Ceramics have enough capacity to accept this new contract in addition to its existing production of 100 plates per day and 100 vases per day? Justify your answer. Answer: Yes No (Bold and underline one) Justify: ___________________________________________________________ _________________________________________________________________

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts