Question: (a) Describe the relationship between ordering cost and setup cost. (3 marks) (b) Explain TWO (2) assumptions of the Economic Order Quantity (EOQ) model. (4

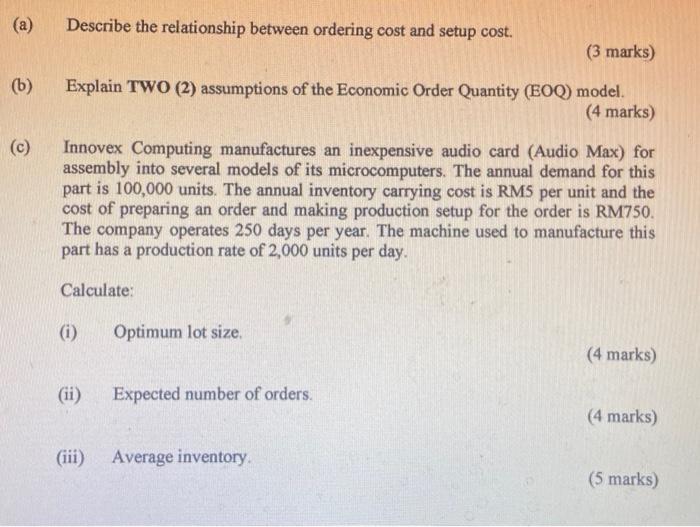

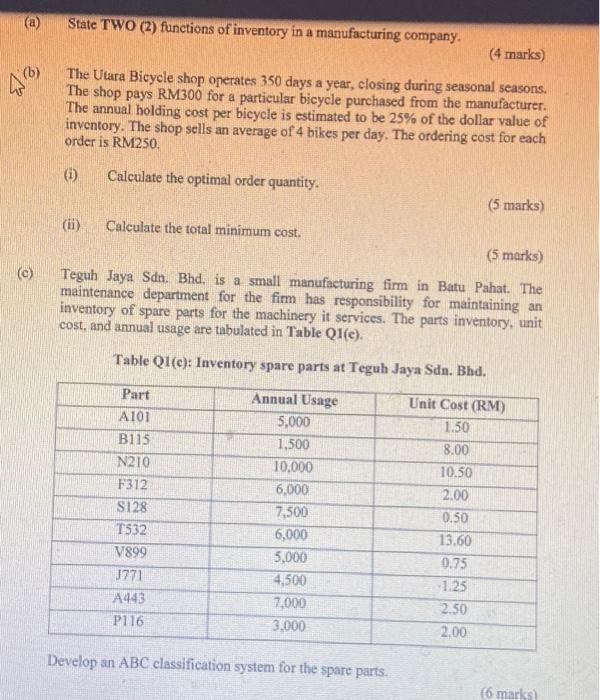

(a) Describe the relationship between ordering cost and setup cost. (3 marks) (b) Explain TWO (2) assumptions of the Economic Order Quantity (EOQ) model. (4 marks) (c) Innovex Computing manufactures an inexpensive audio card (Audio Max) for assembly into several models of its microcomputers. The annual demand for this part is 100,000 units. The annual inventory carrying cost is RMS per unit and the cost of preparing an order and making production setup for the order is RM750. The company operates 250 days per year. The machine used to manufacture this part has a production rate of 2,000 units per day. Calculate: (i) Optimum lot size. (4 marks) (ii) Expected number of orders. (4 marks) (iii) Average inventory. (5 marks) (b) The Utara Bicycle shop operates 350 days a year, closing during seasonal seasons. The shop pays RM300 for a particular bicycle purchased from the manufacturer. The annual holding cost per bicycle is estimated to be 25% of the dollar value of inventory. The shop sells an average of 4 bikes per day. The ordering cost for each order is RM250. (i) Calculate the optimal order quantity. ( 5 marks) (ii) Calculate the total minimum cost. ( 5 marks) (c) Teguh Jaya Sdn. Bhd, is a small manufacturing firm in Batu Pahat. The maintenance department for the firm has responsibility for maintaining an inventory of spare parts for the machinery it services. The parts inventory, unit. cost, and annual usage are tabulated in Table Q1(e). Table QI(c): Inventory spare parts at Teguh Jaya Sdn. Bhd. Develop an ABC classification system for the spare parts

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts