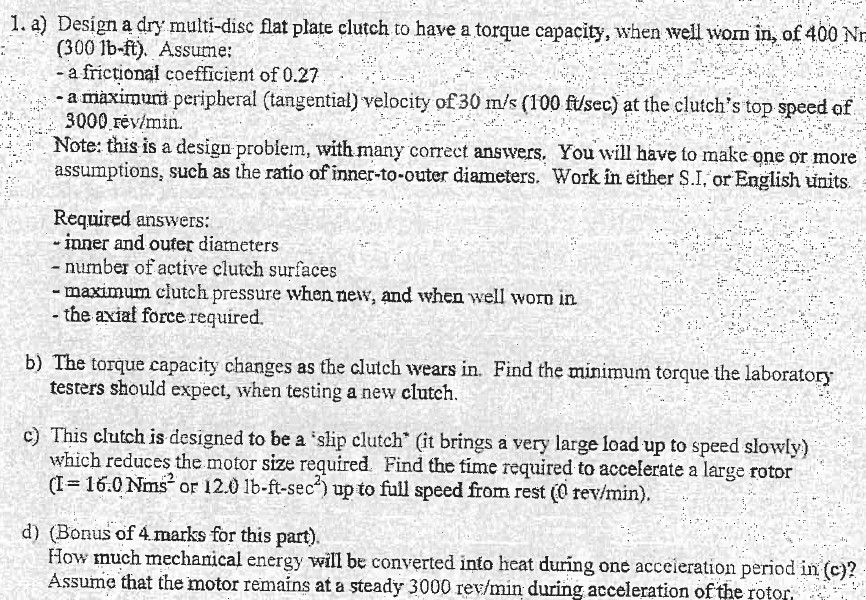

Question: a ) Design a dry multi - disc flat plate clutch to have a torque capacity, when well worn in , of 4 0 0

a Design a dry multidisc flat plate clutch to have a torque capacity, when well worn in of Nr

ft Assume:

a frictional coefficient of

a maximum peripheral tangential velocity of at the clutch's top speed of

revimin.

Note: this is a design problem, with many correct answers, You will have to make one or more

assumptions, such as the ratio of innertoouter diameters. Work in either SI, or English units.

Required answers:

inner and outer diameters

number of active clutch surfaces

maximum clutch pressure when new, and when well worn in

the axial force required.

b The torque capacity changes as the clutch wears in Find the minimum torque the laboratory

testers should expect, when testing a new clutch.

c This clutch is designed to be a "slip clutchit brings a very large load up to speed slowly

which reduces the motor size required. Find the time required to accelerate a large rotor

or : up to full speed from rest

dBonus of marks for this part

How much mechanical energy will be converted into heat during one acceieration period in c

Assume that the motor remains at a steady during acceleration of the rotor.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock