Question: a) Develop another plan for the Mexican roofing manufacturer. For this plan, plan 5, the firm wants to maintain a constant workforce of eight, using

a)

Develop another plan for the Mexican roofing manufacturer. For this plan, plan 5, the firm wants to maintain a constant workforce of eight, using overtime to meet remaining demand. Is this plan preferable?

b)

The same roofing manufacturer has yet a sixth plan. A constant workforce of seven is selected, with the remainder of demand filled by subcontracting. c)

Is this better than plans 15?

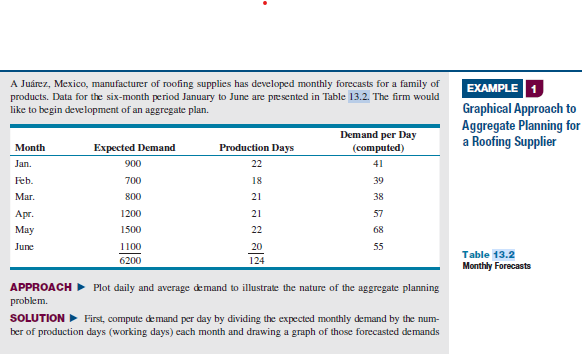

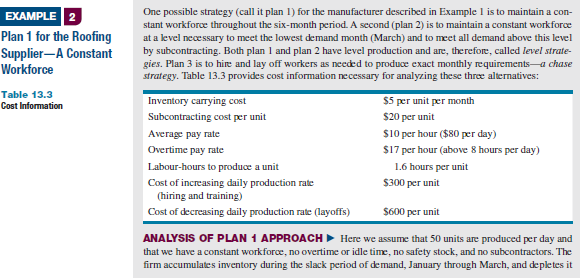

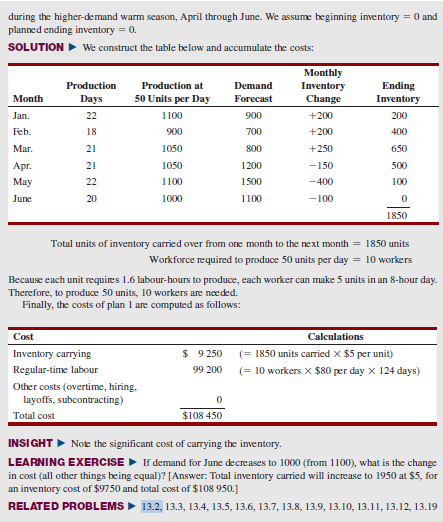

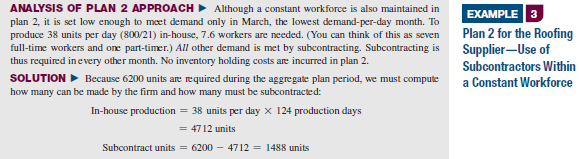

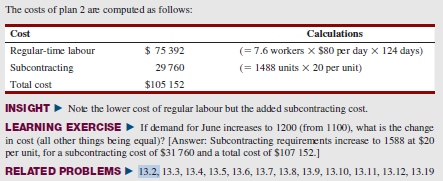

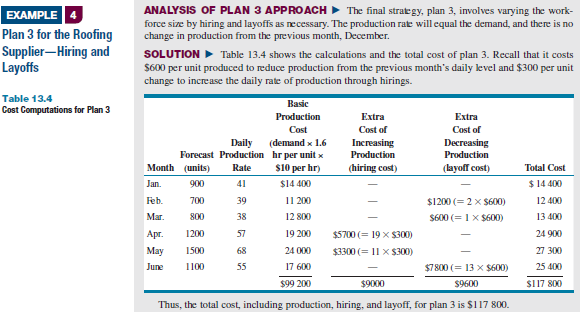

EXAMPLE 1 Graphical Approach to Aggregate Planning for a Roofing Supplier A Jurez, Mexico, manufacturer of roofing supplies has developed monthly forecasts for a family of products. Data for the six-month period January to June are presented in Table 13.2. The firm would like to begin development of an aggregate plan. Demand per Day Month Expected Demand Production Days (computed) Jan. 900 22 41 Feb. 700 18 39 Mar 800 21 38 Apr. 1200 57 May 1500 22 June 1100 20 55 6200 124 21 68 Table 13.2 Monthly Forecasts APPROACH Plot daily and average demand to illustrate the nature of the aggregate planning problem. SOLUTION First, compute demand per day by dividing the expected monthly demand by the num- ber of production days (working days) each month and drawing a graph of those forecasted demands EXAMPLE 2 Plan 1 for the Roofing Supplier-A Constant Workforce Table 13.3 Cost Information One possible strategy (call it plan 1) for the manufacturer described in Example 1 is to maintain a con- stant workforce throughout the six-month period. A second (plan 2) is to maintain a constant workforce at a level necessary to meet the lowest demand month (March) and to meet all demand above this level by subcontracting. Both plan 1 and plan 2 have level production and are, therefore, called level strate- gies. Plan 3 is to hire and lay off workers as needed to produce exact monthly requirementsa chase strategy. Table 13.3 provides cost information necessary for analyzing these three alternatives: Inventory carrying cost $5 per unit per month Subcontracting cost per unit $20 per unit Average pay rate $10 per hour ($80 per day) Overtime pay rate $17 per hour (above 8 hours per day) Labour-hours to produce a unit 1.6 hours per unit Cost of increasing daily production rate $300 per unit (hiring and training) Cost of decreasing daily production rate (layoffs) $600 per unit ANALYSIS OF PLAN 1 APPROACH Here we assume that 50 units are produced per day and that we have a constant workforce, no overtime or idle time, no safety stock, and no subcontractors. The firm accumulates inventory during the slack period of demand, January through March, and depletes it during the higher-demand warm season, April through June. We assume beginning inventory = 0 and planned ending inventory = 0. SOLUTION We construct the table below and accumulate the costs: Monthly Production Production at Demand Inventory Ending Month Days 50 Units per Day Forecast Change Inventory Jan. 22 1100 900 +200 200 Feb. 18 900 700 +200 400 21 1050 800 +250 Apr. 21 1050 1200 - 150 500 May 22 1100 1500 -400 100 June 20 1000 1100 -100 1850 Mar. 650 0 Total units of inventory carried over from one month to the next month = 1850 units Workforce required to produce 50 units per day = 10 workers Because each unit requires 1.6 labour-hours to produce, cach worker can make 5 units in an 8-hour day. Therefore, to produce 50 units, 10 workers are needed. Finally, the costs of plan 1 are computed as follows: Cost Inventory carrying Regular-time labour Other costs (overtime, hiring, layoffs, subcontracting) Total cost $ 9 250 99 200 Calculations (= 1850 units carried x $5 per unit) (= 10 workers X $80 per day x 124 days) 0 $108 450 INSIGHT Note the significant cost of carrying the inventory. LEARNING EXERCISE If demand for June decreases to 1000 (from 1100), what is the change in cost (all other things being equal)? [Answer: Total inventory carried will increase to 1950 at $5, for an inventory cost of $9750 and total cost of $108 950.] RELATED PROBLEMS 13.2, 13.3, 13.4, 13.5, 13.6, 13.7, 13.8, 13.9, 13.10, 13.11, 13.12, 13.19 ANALYSIS OF PLAN 2 APPROACH Although a constant workforce is also maintained in plan 2, it is set low enough to meet demand only in March, the lowest demand-per-day month. To produce 38 units per day (800/21) in-house, 7.6 workers are needed. (You can think of this as seven full-time workers and one part-timer.) All other demand is met by subcontracting. Subcontracting is thus required in every other month. No inventory holding costs are incurred in plan 2. SOLUTION Because 6200 units are required during the aggregate plan period, we must compute how many can be made by the firm and how many must be subcontracted: In-house production = 38 units per day x 124 production days = 4712 units Subcontract units = 6200 - 4712 = 1488 units EXAMPLE 3 Plan 2 for the Roofing Supplier-Use of Subcontractors Within a Constant Workforce The costs of plan 2 are computed as follows: Cost Regular-time labour Subcontracting Total cost $ 75 392 29 760 $105 152 Calculations (= 7.6 workers X $80 per day X 124 days) (= 1488 units x 20 per unit) INSIGHT Note the lower cost of regular labour but the added subcontracting cost. LEARNING EXERCISE If demand for June increases to 1200 (from 1100), what is the change in cost (all other things being equal)? [Answer: Subcontracting requirements increase to 1588 at $20 per unit, for a subcontracting cost of $31 760 and a total cost of $107 152.] RELATED PROBLEMS 13.2, 13.3, 13.4, 13.5, 13.6, 13.7, 13.8, 13.9, 13.10, 13.11, 13.12, 13.19 EXAMPLE Plan 3 for the Roofing Supplier-Hiring and Layoffs ANALYSIS OF PLAN 3 APPROACH The final strategy, plan 3, involves varying the work- force size by hiring and layoffs as necessary. The production rate will equal the demand, and there is no change in production from the previous month, December SOLUTION Table 13.4 shows the calculations and the total cost of plan 3. Recall that it costs $600 per unit produced to reduce production from the previous month's daily level and $300 per unit change to increase the daily rate of production through hirings. Table 13.4 Cost Computations for Plan 3 Rasic Extra Cost of Increasing Production (hiring cost) Extra Cost of Decreasing Production (layoff cost) Production Cost Daily (demand x 1.6 Forecast Production hr per unit Month (units) Rate $10 per hr) Jan. 900 41 $14400 Feb. 700 39 11 200 Mar. 800 38 12 800 Apr. 1200 57 19 200 May 1500 68 24 000 June 1100 55 17 600 $99 200 $1200 (= 2 X $600) $600 (= I x $600) Total Cost $ 14400 12 400 13 400 24 900 27 300 25 400 $117 800 $5700 (= 19 x $300) $3300 (= 11 X $300) $7800 (= 13 x $600) $9600 $9000 Thus, the total cost, including production, hiring, and layoff, for plan 3 is $117 800. INSIGHT Note the substantial cost associated with changing (both increasing and decreasing) the production levels. LEARNING EXERCISE If demand for June increases to 1200 (from 1100), what is the change in cost? [Answer: Daily production for June is 60 units, which is a decrease of 8 units in the daily pro- duction rate from May's 68 units, so the new June layoff cost is $4800 (= 8 x $600), but an additional production cost for 100 units is $1600 (100 X 16 X $10), with a total plan 3 cost of $116,400.] RELATED PROBLEMS 13.2, 13.3, 13.4, 13.5, 13.6, 13.7, 13.8, 13.9, 13.10, 13.11, 13.12, 13.19

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts