Question: A distillation column is a unit operation that is used to separate a mixture into an overhead product and a bottoms product. Due to the

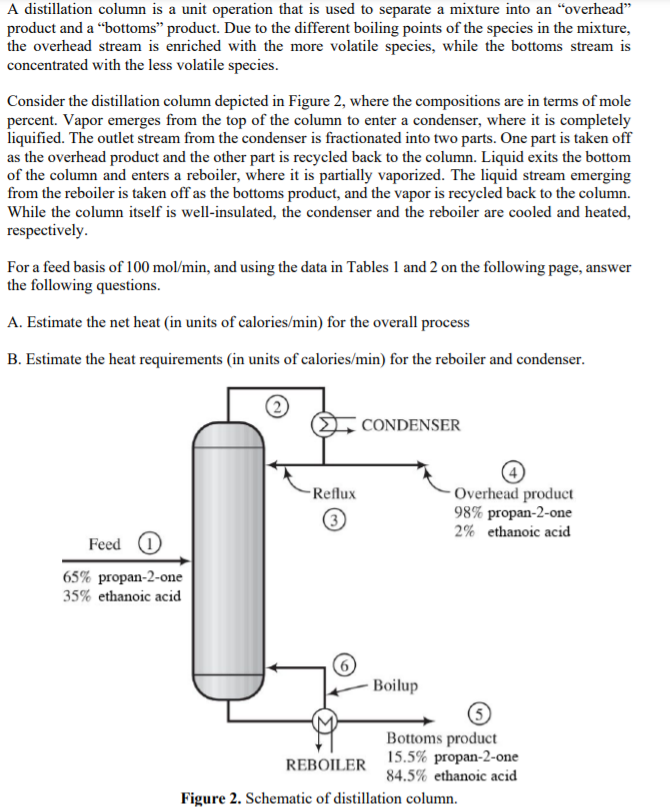

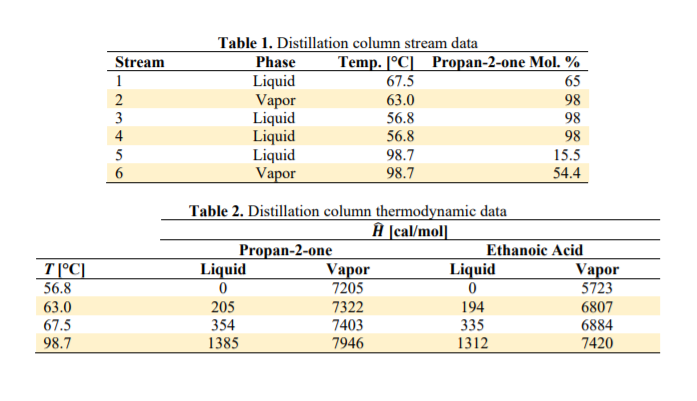

A distillation column is a unit operation that is used to separate a mixture into an "overhead product and a bottoms product. Due to the different boiling points of the species in the mixture, the overhead stream is enriched with the more volatile species, while the bottoms stream is concentrated with the less volatile species. Consider the distillation column depicted in Figure 2, where the compositions are in terms of mole percent. Vapor emerges from the top of the column to enter a condenser, where it is completely liquified. The outlet stream from the condenser is fractionated into two parts. One part is taken off as the overhead product and the other part is recycled back to the column. Liquid exits the bottom of the column and enters a reboiler, where it is partially vaporized. The liquid stream emerging from the reboiler is taken off as the bottoms product, and the vapor is recycled back to the column. While the column itself is well-insulated, the condenser and the reboiler are cooled and heated, respectively. For a feed basis of 100 mol/min, and using the data in Tables 1 and 2 on the following page, answer the following questions. A. Estimate the net heat (in units of calories/min) for the overall process B. Estimate the heat requirements (in units of calories/min) for the reboiler and condenser. CONDENSER Reflux Overhead product 98% propan-2-one 2% ethanoic acid Feed 65% propan-2-one 35% ethanoic acid Boilup Bottoms product REBOILER 15.5% propan-2-one 84.5% ethanoic acid Figure 2. Schematic of distillation column. Table 1. Distillation column stream data Phase Temp. [C] Propan-2-one Mol. % Liquid 67.5 65 Vapor 63.0 Liquid 56.8 98 Liquid 56.8 98 Liquid 98.7 15.5 Vapor 98.7 54.4 Stream 1 2 3 4 5 6 98 T[C] 56.8 63.0 67.5 98.7 Table 2. Distillation column thermodynamic data A cal/mol] Propan-2-one Ethanoic Acid Liquid Vapor Liquid Vapor 0 7205 0 5723 205 7322 194 6807 354 7403 335 6884 1385 7946 1312 7420

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts