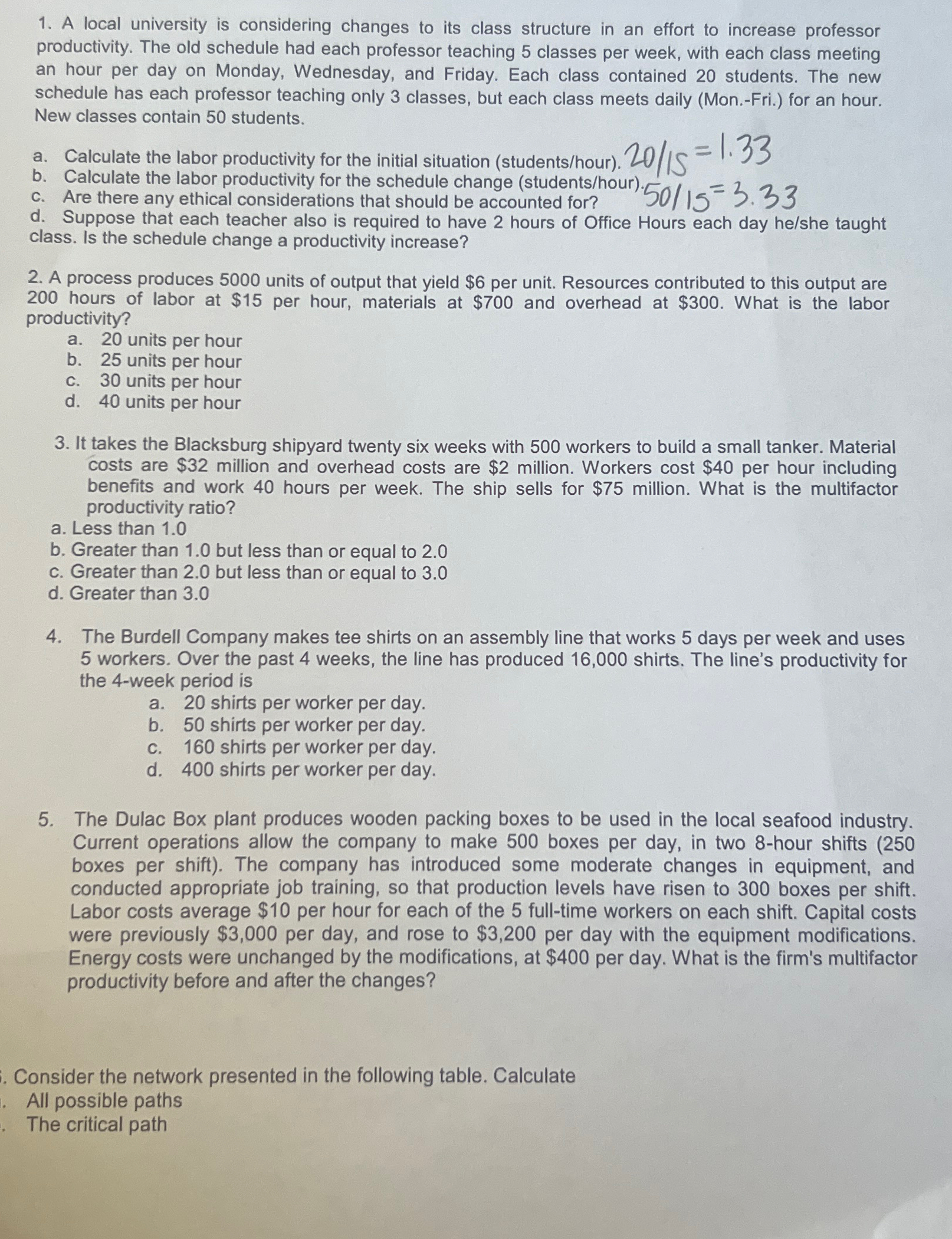

Question: A local university is considering changes to its class structure in an effort to increase professor productivity. The old schedule had each professor teaching 5

A local university is considering changes to its class structure in an effort to increase professor productivity. The old schedule had each professor teaching classes per week, with each class meeting an hour per day on Monday, Wednesday, and Friday. Each class contained students. The new schedule has each professor teaching only classes, but each class meets daily MonFri. for an hour. New classes contain students.

a Calculate the labor productivity for the initial situation studentshour

b Calculate the labor productivity for the schedule change studentshour

d Suppose that each teacher also is required to have hours of Office Hours each day heshe taught class. Is the schedule change a productivity increase?

A process produces units of output that yield $ per unit. Resources contributed to this output are hours of labor at $ per hour, materials at $ and overhead at $ What is the labor productivity?

a units per hour

b units per hour

c units per hour

d units per hour

It takes the Blacksburg shipyard twenty six weeks with workers to build a small tanker Material costs are $ million and overhead costs are $ million. Workers cost $ per hour including benefits and work hours per week. The ship sells for $ million. What is the multifactor productivity ratio?

a Less than

b Greater than but less than or equal to

c Greater than but less than or equal to

d Greater than

The Burdell Company makes tee shirts on an assembly line that works days per week and uses workers. Over the past weeks, the line has produced shirts. The line's productivity for the week period is

a shirts per worker per day.

b shirts per worker per day.

c shirts per worker per day.

d shirts per worker per day.

The Dulac Box plant produces wooden packing boxes to be used in the local seafood industry. Current operations allow the company to make boxes per day, in two hour shifts boxes per shift The company has introduced some moderate changes in equipment, and conducted appropriate job training, so that production levels have risen to boxes per shift. Labor costs average $ per hour for each of the fulltime workers on each shift. Capital costs were previously $ per day, and rose to $ per day with the equipment modifications. Energy costs were unchanged by the modifications, at $ per day. What is the firm's multifactor productivity before and after the changes?

Consider the network presented in the following table. Calculate

All possible paths

The critical path

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock