Question: A manager must set up inventory ordering system for two new production items, P34 and P35. P34 can be ordered anytime, but P35 can be

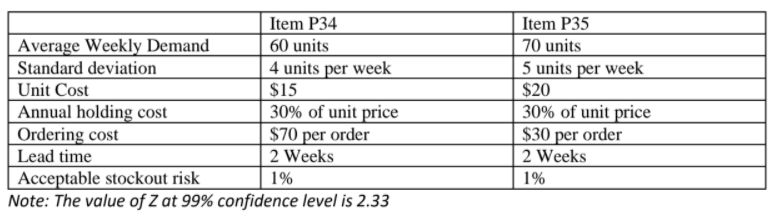

A manager must set up inventory ordering system for two new production items, P34 and P35. P34 can be ordered anytime, but P35 can be ordered only once every four weeks. The company operate 50 weeks a year and weekly usage rates both items are normally distributed. The manager has gathered the following information about the items:

a. Compute the order quantity and Reorder Point (ROP) for P34? b. Compute the Order quantity for P35 if 110 units are on hand at the time of the order is placed? c. What are the safety stocks for P34 and P35?

a. Compute the order quantity and Reorder Point (ROP) for P34? b. Compute the Order quantity for P35 if 110 units are on hand at the time of the order is placed? c. What are the safety stocks for P34 and P35?

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts