Question: A manager must set up inventory ordering systems for two new items, Gadget and Widget. Gadget is ordered from a supplier and is delivered at

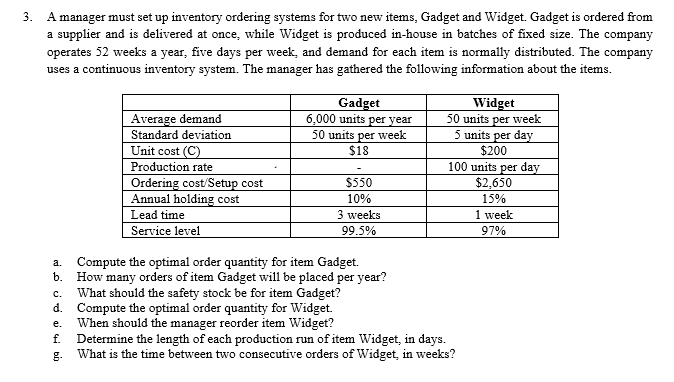

A manager must set up inventory ordering systems for two new items, Gadget and Widget. Gadget is ordered from a supplier and is delivered at once, while Widget is produced inhouse in batches of fixed size. The company operates weeks a year, five days per week, and demand for each item is normally distributed. The company uses a continuous inventory system. The manager has gathered the following information about the items.

tableGadget,WidgetAverage demand, units per year, units per weekStandard deviation, units per week, units per dayUnit cost C$$Production rate, units per dayOrdering costSetup cost$$Annual holding cost,Lead time, weeks, weekService level,

a Compute the optimal order quantity for item Gadget.

b How many orders of item Gadget will be placed per year?

c What should the safety stock be for item Gadget?

d Compute the optimal order quantity for Widget.

e When should the manager reorder item Widget?

f Determine the length of each production run of item Widget, in days.

g What is the time between two consecutive orders of Widget, in weeks?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock