Question: A microwelding process uses a laser to weld two stainless steel micro - wires, each with a diameter of ( mathbf { 1

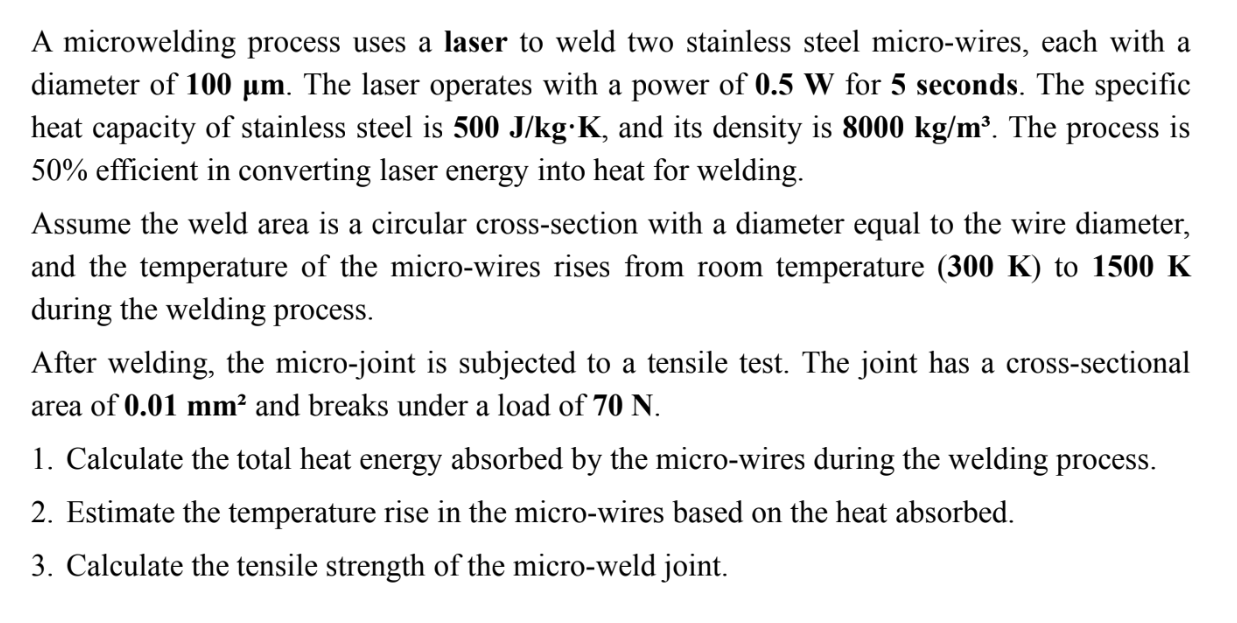

A microwelding process uses a laser to weld two stainless steel microwires, each with a diameter of mathbfboldsymbolmu m The laser operates with a power of mathbfmathbfW for mathbf seconds. The specific heat capacity of stainless steel is mathbfmathbfJmathbfk gcdot mathbfK and its density is mathbfmathbf~ k gmathbfmmathbf The process is efficient in converting laser energy into heat for welding.

Assume the weld area is a circular crosssection with a diameter equal to the wire diameter, and the temperature of the microwires rises from room temperature mathbfmathbf~ K to mathbfmathbfK during the welding process.

After welding, the microjoint is subjected to a tensile test. The joint has a crosssectional area of mathbfmathbfm mmathbf and breaks under a load of mathbfmathbfN

Calculate the total heat energy absorbed by the microwires during the welding process.

Estimate the temperature rise in the microwires based on the heat absorbed

Calculate the tensile strength of the microweld joint.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock