Question: .. A new shell and tube condenser has been installed on a steam power plant with one shell pass and two tube passes. The

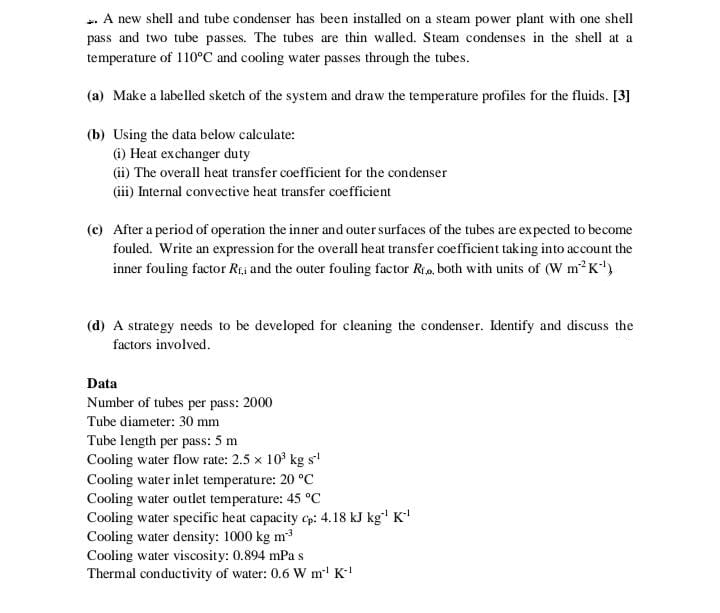

.. A new shell and tube condenser has been installed on a steam power plant with one shell pass and two tube passes. The tubes are thin walled. Steam condenses in the shell at a temperature of 110C and cooling water passes through the tubes. (a) Make a labelled sketch of the system and draw the temperature profiles for the fluids. [3] (b) Using the data below calculate: (i) Heat exchanger duty (ii) The overall heat transfer coefficient for the condenser (iii) Internal convective heat transfer coefficient (c) After a period of operation the inner and outer surfaces of the tubes are expected to become fouled. Write an expression for the overall heat transfer coefficient taking into account the inner fouling factor R, and the outer fouling factor Rio, both with units of (W mK) (d) A strategy needs to be developed for cleaning the condenser. Identify and discuss the factors involved. Data Number of tubes per pass: 2000 Tube diameter: 30 mm Tube length per pass: 5 m Cooling water flow rate: 2.5 x 10 kg s Cooling water inlet temperature: 20 C Cooling water outlet temperature: 45 C Cooling water specific heat capacity cp: 4.18 kJ kg K Cooling water density: 1000 kg m- Cooling water viscosity: 0.894 mPa s Thermal conductivity of water: 0.6 W m K-

Step by Step Solution

3.40 Rating (153 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts