A PLC is used to count the number of cans traveling by on a conveyor belt...

Fantastic news! We've Found the answer you've been seeking!

Question:

Transcribed Image Text:

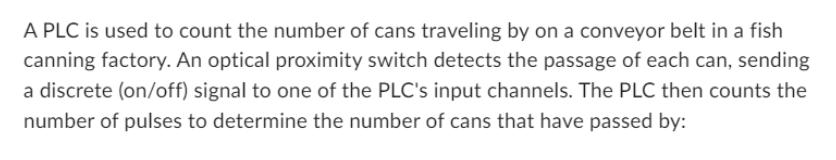

A PLC is used to count the number of cans traveling by on a conveyor belt in a fish canning factory. An optical proximity switch detects the passage of each can, sending a discrete (on/off) signal to one of the PLC's input channels. The PLC then counts the number of pulses to determine the number of cans that have passed by: 120 VAC Power supply 24 VDC L1 L2/N Gnd TB-23 10 20 39 Processor Input 00 Gm Red Blu Org DC sourcing INO >>> IN1 IN2 IN3 INA IN5 ING INT- Counter reset COM COM Input DC sinking INO >> IN1 IN2 IN3 IN4 INS ING IN7 COM COM TB-20 10 20 30 Output DC sinking VDC OUTO OUT1 OUT2 OUT3 OUT4 OUTS OUT6 OUT7 COM Cable 45 TB-31 O NO Bik Om O |0|||0|||0|||0| Wht DC sinking Red One day the canning line operator tells you the PLC has stopped counting even though cans continue to run past the proximity switch as the conveyor belt moves. Identify what you would do to begin diagnosing this problem, justifying each step you would take. A PLC is used to count the number of cans traveling by on a conveyor belt in a fish canning factory. An optical proximity switch detects the passage of each can, sending a discrete (on/off) signal to one of the PLC's input channels. The PLC then counts the number of pulses to determine the number of cans that have passed by: 120 VAC Power supply 24 VDC L1 L2/N Gnd TB-23 10 20 39 Processor Input 00 Gm Red Blu Org DC sourcing INO >>> IN1 IN2 IN3 INA IN5 ING INT- Counter reset COM COM Input DC sinking INO >> IN1 IN2 IN3 IN4 INS ING IN7 COM COM TB-20 10 20 30 Output DC sinking VDC OUTO OUT1 OUT2 OUT3 OUT4 OUTS OUT6 OUT7 COM Cable 45 TB-31 O NO Bik Om O |0|||0|||0|||0| Wht DC sinking Red One day the canning line operator tells you the PLC has stopped counting even though cans continue to run past the proximity switch as the conveyor belt moves. Identify what you would do to begin diagnosing this problem, justifying each step you would take.

Expert Answer:

Related Book For

Automation Production Systems and Computer Integrated Manufacturing

ISBN: 978-0132393218

3rd edition

Authors: Mikell P.Groover

Posted Date:

Students also viewed these mechanical engineering questions

-

An algorithm has been written in pseudocode to input some numbers. It only outputs any numbers that are greater than or equal to 100. The number 999 is not output and stops the algorithm. INPUT...

-

Write a program to count the number of times the words in an input text file occur. The WordCount Structure Define a C++ struct called WordCount that contains the following data members: An array of...

-

8 Assume a company reported the following results: Sales Net operating income Average operating assets Margin Turnover Return on investment (ROI) What is the return on investment? ? $ 120,000 $...

-

Points A and B are separated by a lake. To find the distance between them, a surveyor locates a point C on land such that CAB = 48.8? He also measures CA as 311 ft and CB as 527 ft. find the distance...

-

Lilly Painting Company is considering whether to purchase a new spray paint machine that costs $4,000. The machine is expected to save labor, increasing net income by $600 per year. The effective...

-

Consider the output of a regression using one explanatory variable on \(n=3\) observations. The residuals and leverages are: Compute the PRESS statistic. i 1 2 3 Residuals ei Leverages hi 3.181...

-

Select a company you are interested in and obtain its annual reports by going to the companys website. Download the annual report for the most recent year. (On many companies websites, you will need...

-

The group project will involve students working in groups to develop a new social innovation for their own start-up business that addresses a well-defined social problem or contributes to a clear...

-

Kevin Brownis the management accountant at and Sons Bank. Some of his colleagues attended a conference recently where they learned that machine learning can be used to accurately predict loan...

-

Write a paper on PVC polyvinyl chloride or aluminum.

-

Question 1: What IS company culture? (remember to identify your source) Question 2: What role does company culture have on organizational success (or lack of success)? Question 3: The reading...

-

Describe exactly how and on what basis job holders will be compensated. Be specific about your compensation plan. Use the motivation theories from the class to support/justify your compensation...

-

The context for the exam is the following case that we discussed in class: (Bombardier) Benoit Aubert, Simon Bourdeau, and Brett Walker. "Successfully Navigating the Turbulent Skies of a Large-Scale...

-

Identify internal organizational factors that trigger change. Identify and explain the environmental pressures that can trigger organizational change. Explain why organizations often fail to change...

-

43 A user installs new antivirus software on a PC, runs all available updates from the manufacturer of the antivirus software, and then starts a scan of the computer using the antivirus software....

-

2: Command line, Functions and Recursion Write a C program that takes a command line argument of a number that you need to calculate the factorial value of. The program must use a recursive function...

-

Suppose that you are part of a virtual team and must persuade other team members on an important matter (such as switching suppliers or altering the project deadline). Assuming that you cannot visit...

-

Five machines will constitute a GT cell. The from to data for the machines are shown in the table below. (a) Determine the most logical sequence of machines for this data, and construct the network...

-

What is shop floor control?

-

What is the resolution of an analog-to-digital converter?

-

Compare different cooling schedule of simulated annealing.

-

Discuss the perturbation mechanism of simulated annealing.

-

What are the pros and cons of GA and SA? Can we conceive of a framework that combines the best of both worlds?

Study smarter with the SolutionInn App