Question: A product is produced by assembling four types of components, and it will be manufactured at a rate of 3,000 units per year after inspections.

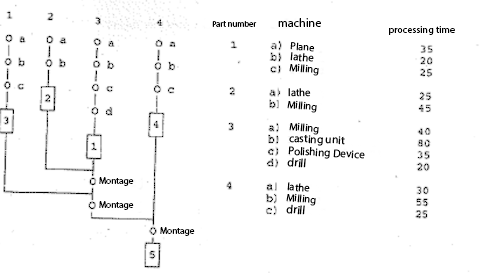

A product is produced by assembling four types of components, and it will be manufactured at a rate of 3,000 units per year after inspections. The process flowchart for this product, along with the machines required and their processing times (in minutes) for each component, is shown below:

The defective part rates for inspections are 2% - 2.5% - 3% - 2.5% - 3.5% in the order of 1-2-3-4-5. Defective parts are scrapped. Calculate the required number of machines for the process flow layout.

(Working capacity is assumed to be 2,400 hours per year). How many workstations should be used in the layout for the desired production quantity of this product, considering the product and the process?

Layout by product: ?

Layout by process: ?

Part number machine processing time 1.a)Planeb)lathec)Milling2a)latheb)Milling34c)drill35202525452)Millingb)castingunitc)PolishingDeviced)drilla)latheb)Milling25408035203055

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts