Question: A production line that assembles computer keyboards has been experiencing problems since a new process was introduced. The supervisor notes that there has been

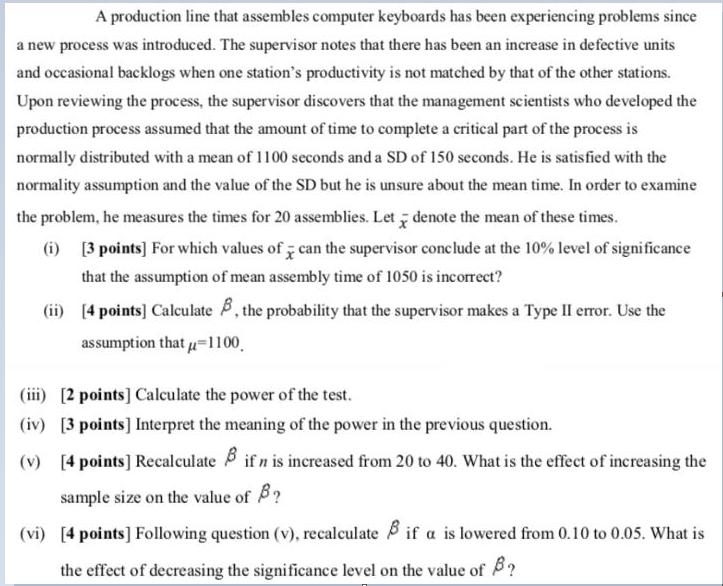

A production line that assembles computer keyboards has been experiencing problems since a new process was introduced. The supervisor notes that there has been an increase in defective units and occasional backlogs when one station's productivity is not matched by that of the other stations. Upon reviewing the process, the supervisor discovers that the management scientists who developed the production process assumed that the amount of time to complete a critical part of the process is normally distributed with a mean of 1100 seconds and a SD of 150 seconds. He is satisfied with the normality assumption and the value of the SD but he is unsure about the mean time. In order to examine the problem, he measures the times for 20 assemblies. Let denote the mean of these times. (i) [3 points] For which values of can the supervisor conclude at the 10% level of significance that the assumption of mean assembly time of 1050 is incorrect? (ii) [4 points] Calculate , the probability that the supervisor makes a Type II error. Use the assumption that u=1100. (iii) [2 points] Calculate the power of the test. (iv) [3 points] Interpret the meaning of the power in the previous question. (v) [4 points] Recalculate if n is inereased from 20 to 40. What is the effect of increasing the sample size on the value of B? (vi) [4 points] Following question (v), recalculate B if a is lowered from 0.10 to 0.05. What is the effect of decreasing the significance level on the value of B?

Step by Step Solution

3.32 Rating (155 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts

Document Format (2 attachments)

635d9b985cf84_177236.pdf

180 KBs PDF File

635d9b985cf84_177236.docx

120 KBs Word File