Question: A quality specialist has collected data from a process which involves the assembly of odometers into the instrument panels. Each hour at the beginning

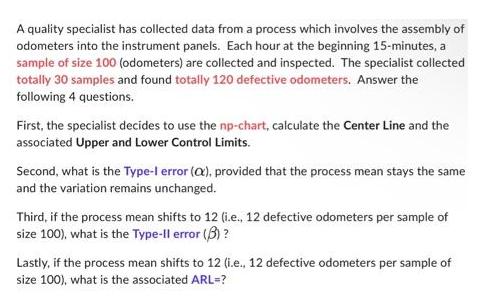

A quality specialist has collected data from a process which involves the assembly of odometers into the instrument panels. Each hour at the beginning 15-minutes, a sample of size 100 (odometers) are collected and inspected. The specialist collected totally 30 samples and found totally 120 defective odometers. Answer the following 4 questions. First, the specialist decides to use the np-chart, calculate the Center Line and the associated Upper and Lower Control Limits. Second, what is the Type-l error (O), provided that the process mean stays the same and the variation remains unchanged. Third, if the process mean shifts to 12 (i.e., 12 defective odometers per sample of size 100), what is the Type-Il error (3) ? Lastly, if the process mean shifts to 12 (i.e., 12 defective odometers per sample of size 100), what is the associated ARL=?

Step by Step Solution

There are 3 Steps involved in it

First we need to calculate the Center Line Upper Control Limit UCL and Lower Control Limit LCL for the npchart The npchart is used to monitor the coun... View full answer

Get step-by-step solutions from verified subject matter experts