Question: A shell and tube heat exchanger has a shell inner diameter of 45 inches and 550 tubes that are 12 ft long on a 1

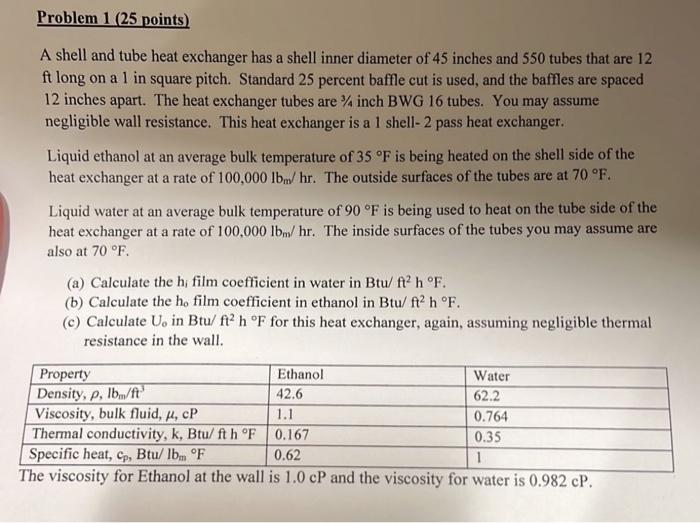

A shell and tube heat exchanger has a shell inner diameter of 45 inches and 550 tubes that are 12 ft long on a 1 in square pitch. Standard 25 percent baffle cut is used, and the baffles are spaced 12 inches apart. The heat exchanger tubes are 3/4 inch BWG 16 tubes. You may assume negligible wall resistance. This heat exchanger is a 1 shell- 2 pass heat exchanger. Liquid ethanol at an average bulk temperature of 35F is being heated on the shell side of the heat exchanger at a rate of 100,000lbm/hr. The outside surfaces of the tubes are at 70F. Liquid water at an average bulk temperature of 90F is being used to heat on the tube side of the heat exchanger at a rate of 100,000lbm/hr. The inside surfaces of the tubes you may assume are also at 70F. (a) Calculate the hi film coefficient in water in Btu/ft2hF. (b) Calculate the ho film coefficient in ethanol in Btu/At2hF. (c) Calculate U0 in Btu/ft2hF for this heat exchanger, again, assuming negligible thermal resistance in the wall. he viscosity for Ethanol at the wall is 1.0cP and the viscosity for water is 0.982cP

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts